Automatic temperature-controllable speed-regulatable mixing mechanism for powder coating

A powder coating and mixing technology, which is applied in the direction of shaking/oscillating/vibrating mixers, mixers, mixer accessories, etc., can solve the problems of inability to meet mixing requirements, low mixing adjustability, inability to mix and stir temperature control and Speed regulation and other issues to achieve the effect of promoting regulation, improving efficiency and quality, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

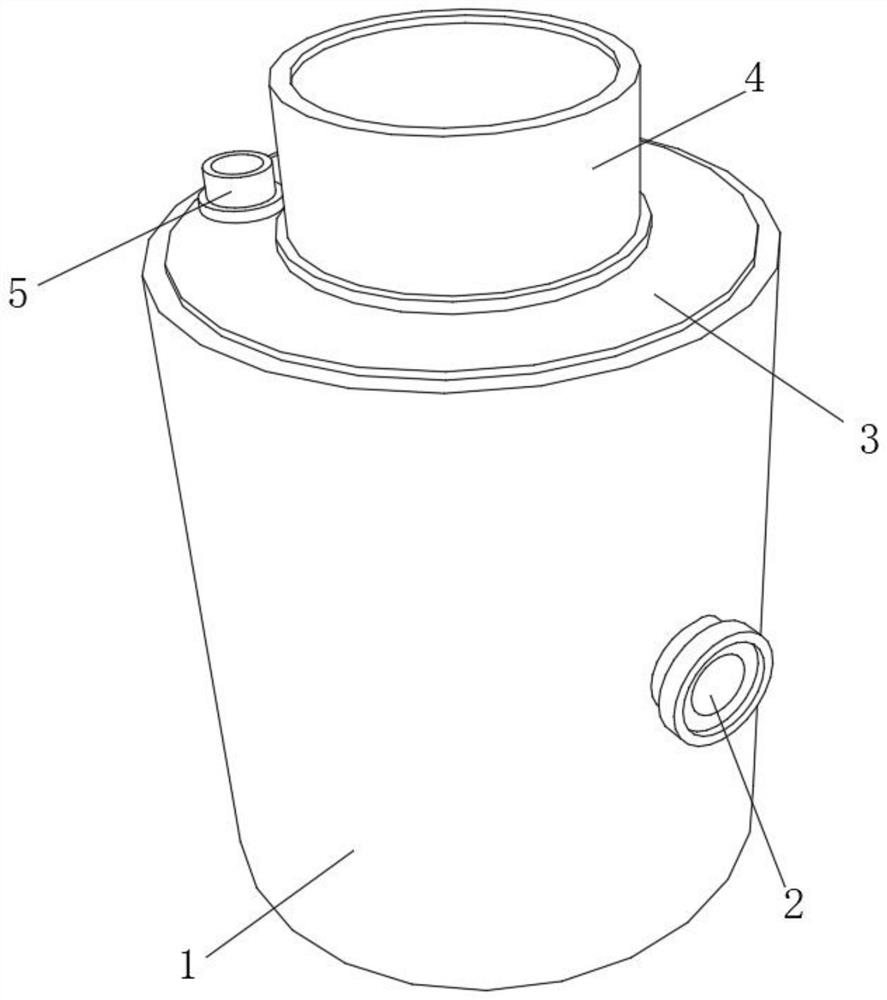

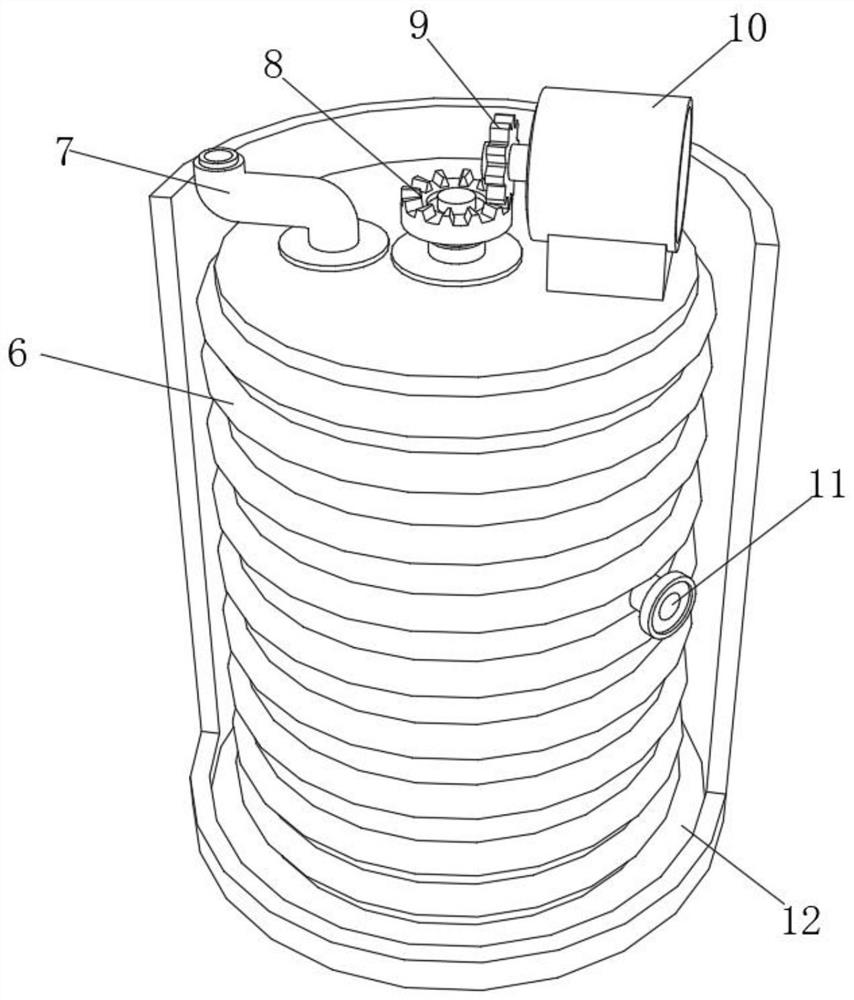

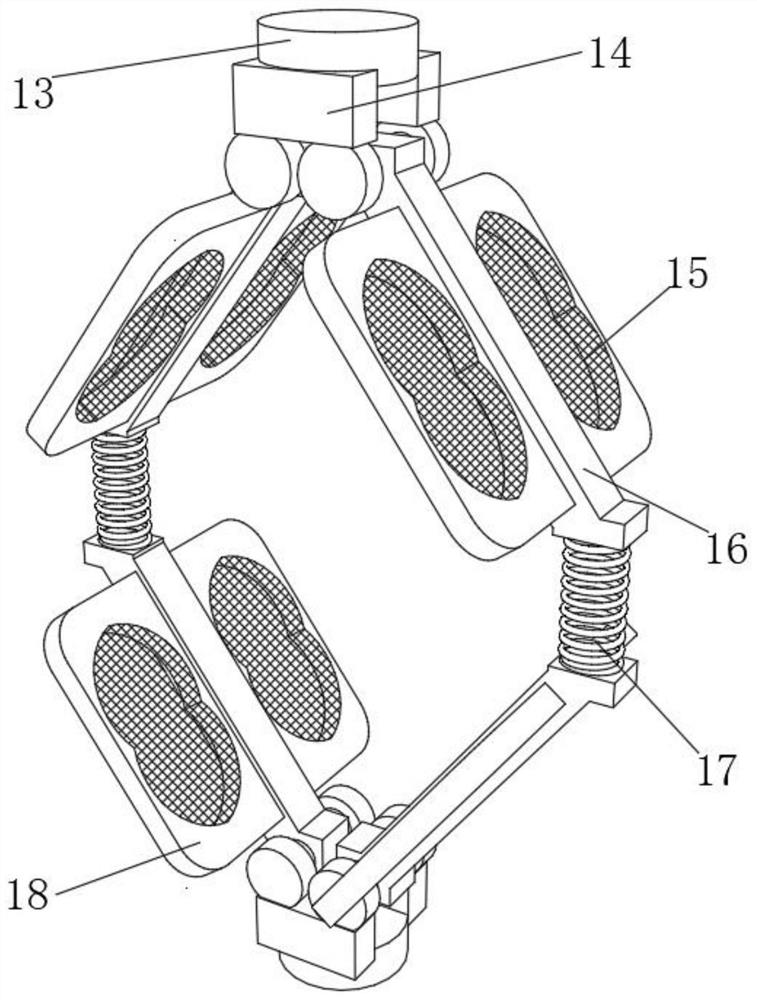

[0032] A powder coating automatic temperature control and speed regulation mixing mechanism, such as Figure 1-4 As shown, a main body box 1 is included, and one side outer wall of the main body box 1 is threadedly connected with a feed port 2, and the top outer wall of the main body box 1 is connected with a top cover 3 through a hinge, and the top outer wall of the top cover 3 is fixed with an organic cover by bolts 4. The outer wall of the top side of the top cover 3 is fixed with a feed port 5 through threads, and the inner wall of the bottom of the main body box 1 is fixed with a corrugated tube 6 through bolts, and the structure of the corrugated tube 6 is not limited, and it can be a cylindrical structure, a rhombus Tube structure, etc., the main body box 1 is provided with a limit groove 12 near the inside of the corrugated tube 6, and the outer wall of one side of the corrugated tube 6 is fixed with a connecting nozzle 11 through threads, and the outer wall of the top ...

Embodiment 2

[0037] A powder coating automatic temperature control and speed regulation mixing mechanism, such as Figure 5 As shown, in order to ensure the telescopic effectiveness of the elastic telescopic stirring mechanism; this embodiment makes the following improvements on the basis of Embodiment 1: the inner walls around the corrugated cylinder 6 are respectively bonded with buffer strips 22; through the setting of the buffer strips 22 , to ensure that the guide frame 18 inside the elastic telescopic stirring mechanism does not have sideways problems during the movement process, ensuring the stability of its movement, thereby indirectly promoting the fluency of mixing and stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com