Efficient filter

A high-efficiency filter and coating technology, applied in the field of medical devices, can solve the problems of filter membrane breakage, drug solution filtration failure, and low membrane strength, and achieve the effect of avoiding failure and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

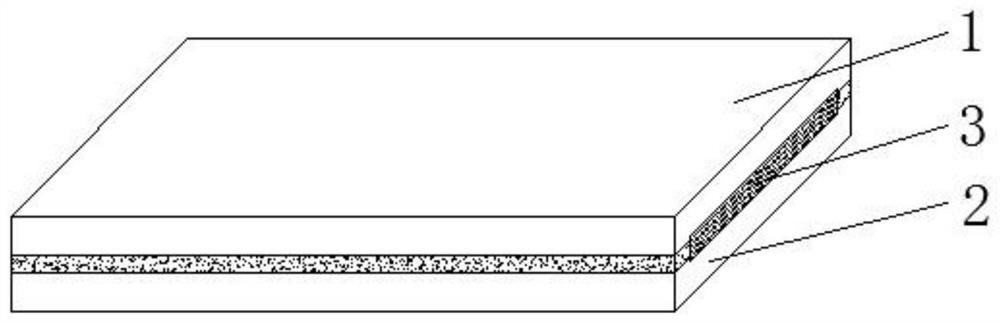

[0019] see figure 1 , this embodiment discloses a high-efficiency filter, including: a first coating layer 1, a second coating layer 2 and a heavy ion microporous membrane layer 3, the first coating layer 1 and the second coating layer 2 form A through cavity for accommodating the heavy ion microporous membrane layer 3 .

[0020] In this embodiment, the first cladding layer 1, the second cladding layer 2 and the heavy ion microporous membrane layer 3 are all sheet-like structures, and the thicknesses of the first cladding layer 1 and the second cladding layer 2 are equal. The first cladding layer 1 and the second cladding layer 2 are butted on opposite sides of the heavy ion microporous membrane layer 3, specifically, the first cladding layer 1 and the second cladding layer 2 are polyethylene sheet structures, It is made of polyethylene powder by die-casting and shaping, and has air permeability. The first coating layer 1 is arranged above the heavy ion microporous membrane l...

Embodiment 2

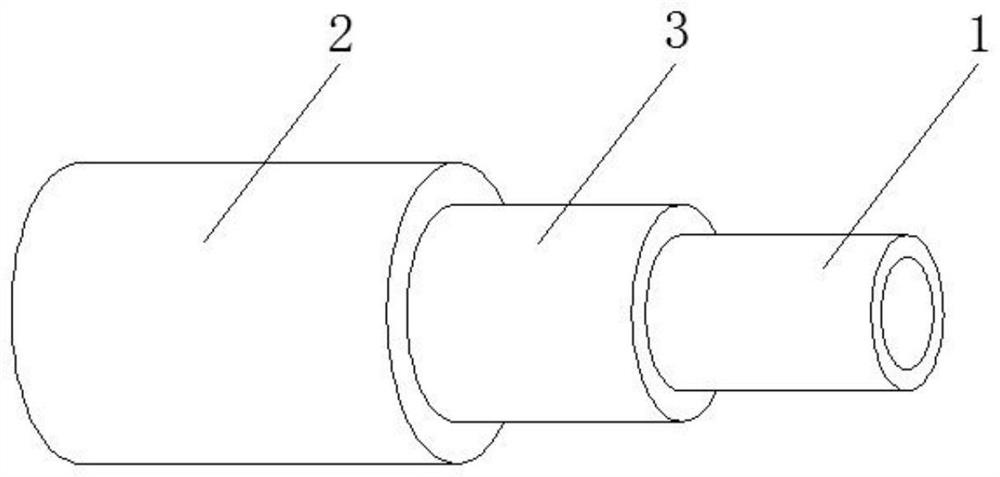

[0022] see figure 2 , this embodiment discloses a high-efficiency filter, including: a first coating layer 1, a second coating layer 2 and a heavy ion microporous membrane layer 3, the first coating layer 1 and the second coating layer 2 form A through cavity for accommodating the heavy ion microporous membrane layer 3 .

[0023] In this embodiment, the first cladding layer 1, the second cladding layer 2 and the heavy ion microporous membrane layer 3 are all tubular structures, and the first cladding layer 1 is arranged on the inner wall of the heavy ion microporous membrane layer 3, The second cladding layer 2 is arranged on the outer wall of the heavy ion microporous membrane layer 3 . Specifically, both the first cladding layer 1 and the second cladding layer 2 are tubular structures formed of a polyethylene sheet structure, the thickness of the first cladding layer 1 and the second cladding layer 2 are equal, and the polyethylene powder is used for die-casting, It is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com