Light-bulb voltage resistance detection device

A technology for pressure resistance detection and light bulbs, which is applied to measuring devices, using stable tension/pressure testing materials, instruments, etc., can solve the problems of easily damaged seals, bulb breakouts, and unsmooth driving of the ejector rod. Easy to damage, not easy to break, smooth moving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

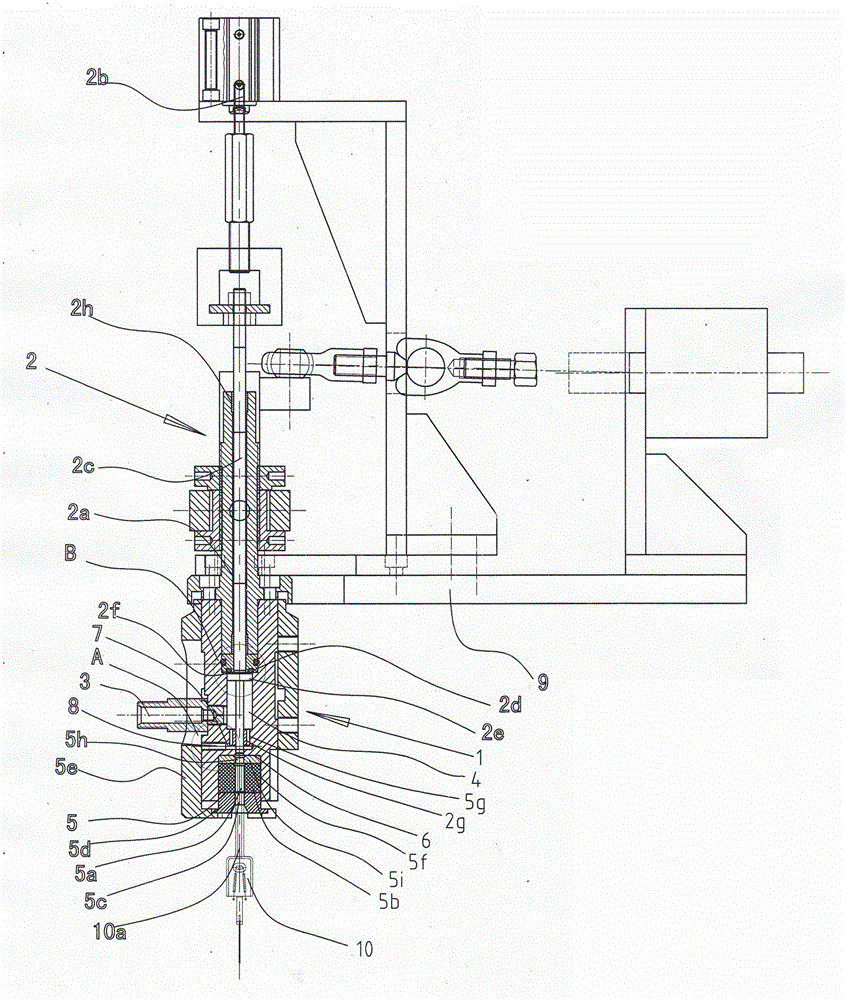

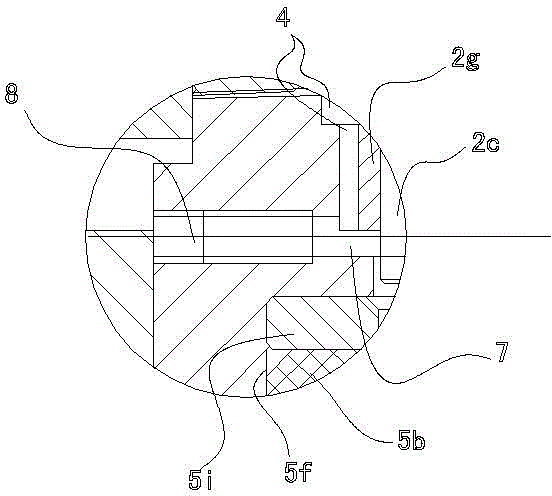

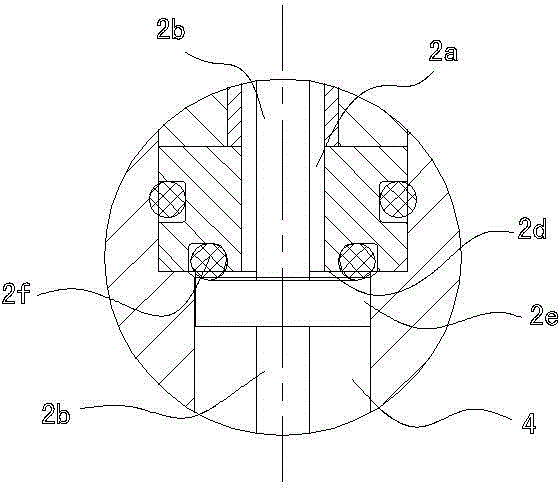

[0014] As shown in the figure, the present invention includes an inflation detection part 1 and a waste bulb cleaning part 2. The inflation detection part includes an air chamber 4 with a pressure gas inlet 3, a bulb sealing and fixing mechanism 5 located under the air chamber 4, and the air chamber 4 The bottom is provided with a stop surface 6, and the bulb sealing and fixing mechanism 5 includes a locking rubber particle 5b with a vertical perforation 5a in the middle of the bottom of the air chamber 4 and a locking rubber particle 5b located on both sides of the outlet of the air guide hole 5g. The following briquetting block 5d with the perforation 5c corresponding to the vertical perforation 5a of the locking colloidal particle 5b, the power moving mechanism 5e that drives the briquetting block 5d to move up and down, the waste bulb cleaning part 2 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com