Novel closed cooling tower adopting glass lining finned tube

A closed cooling tower, finned tube technology, applied in water shower coolers, heat exchanger types, direct contact heat exchangers, etc. Prolonged service life, good latent heat of evaporation, good heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

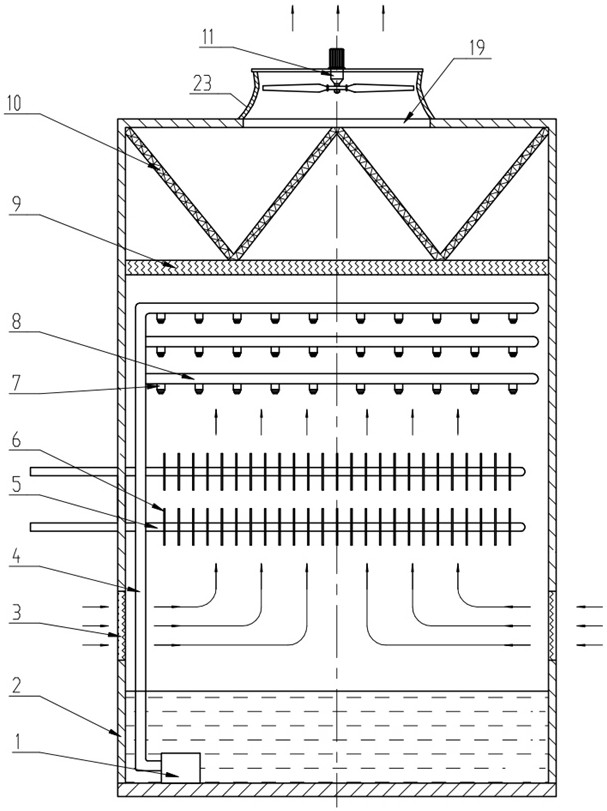

[0035] Such as figure 1 As shown, a new type of closed cooling tower adopting glass-lined finned tubes includes a rectangular box 2, and the inside of the box 2 is sequentially provided with a water storage layer, a heat exchange layer, and a water recovery layer for recycling water. The recycling layer for the fog. The water storage layer is located at the bottom of the box body 2, and water is stored inside it. The lower part of the heat exchange layer is provided with air inlets 3 on the walls of the four sides of the box body 2, and the air inlets 3 are all provided with louvers. The center of the top of the box body 2 is provided with an air outlet 19, and the outside of the box body 2 is welded with a shroud 23 at the air outlet 19, and the inside of the shroud is fixedly connected with a fan 11, and the type of the fan 11 is a shaft. streaming.

[0036] The water storage layer is arranged at the bottom of the box body 2, and the heat exchange layer includes a horizon...

Embodiment 2

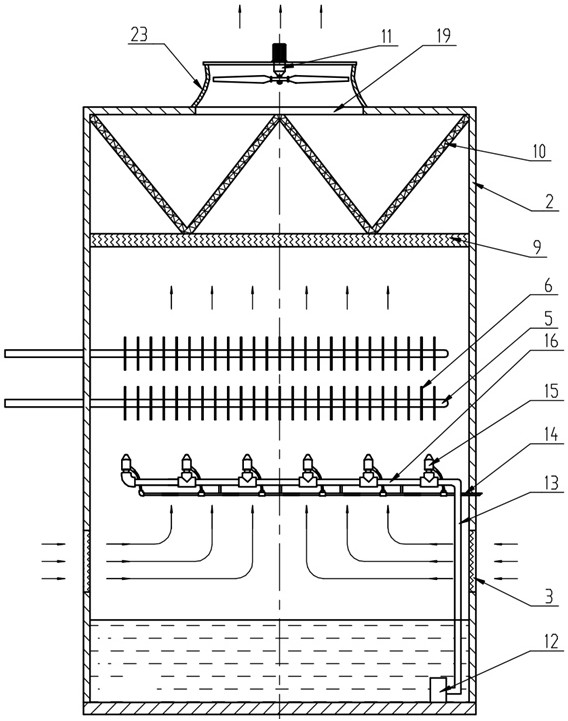

[0045] Such as figure 2 Shown, the difference between this embodiment and embodiment 1 is:

[0046] The spraying device is replaced with a spraying device, and the spraying device includes a horizontal spraying water pipe 16, a horizontal air supply pipe 14 arranged below the spraying water pipe 16, an atomizing nozzle 15 uniformly distributed along the spraying water pipe 16 and fixedly connected thereto And the vertical second water supply pipe 13 that connects the spray water pipe 16 with the water storage layer. The atomizing nozzles 15 are all upward toward the coil pipe 5, and the air inlets of the atomizing nozzles 15 are all connected to the air supply pipe 14, and the air supply pipe 14 passes through the side wall of the box body 2 to the right and is connected to the compressed air pipeline . The lower end of the second water supply pipe 13 is provided with a spray pump 12, the spray pump 12 is a submersible pump B installed in the water of the water storage laye...

Embodiment 3

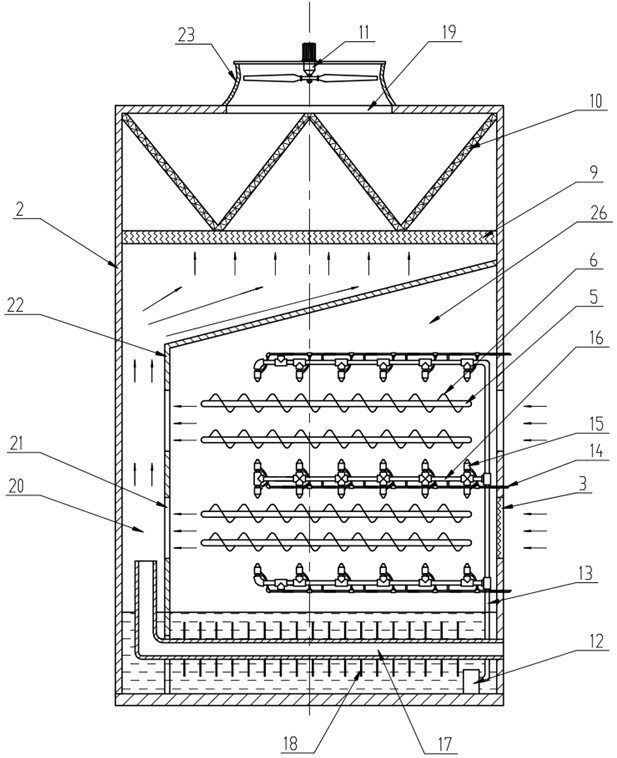

[0050] Such as image 3 As shown, the box body 2 is welded with a Γ-shaped partition 22 in the heat exchange layer, and the partition 22 is composed of a vertical vertical plate and a slant plate welded on the top of the vertical plate. The lower end of the vertical plate extends below the water surface of the water storage layer, and the partition plate 22 separates the heat exchange layer into a heat exchange chamber on the right and an air channel 20 on the left. The water storage layers on the left and right sides of the riser are connected at the bottom of the box body 2 . The vertical plate is provided with a middle hole 21, and the middle hole 21 connects the heat exchange chamber and the air duct 20 horizontally. The top of the air duct 20 communicates with the recovery layer, and the wind direction in the heat exchange chamber is horizontal.

[0051] The coiled pipe 5 has 4 layers in total, and two layers form a group. A spray water pipe 16 and an atomizing nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com