Oil supply detection device for engine of lifeboat of ship

A detection device and engine technology, applied in the direction of engine components, machines/engines, pump devices, etc., can solve problems such as reducing engine oil supply efficiency, unable to adjust the oil supply balance independently, and engine stop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

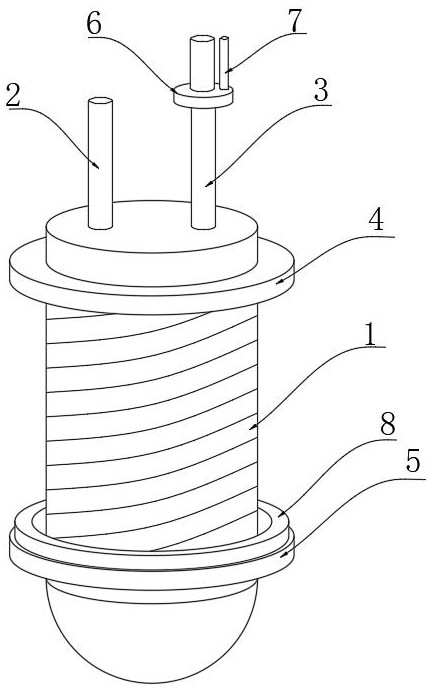

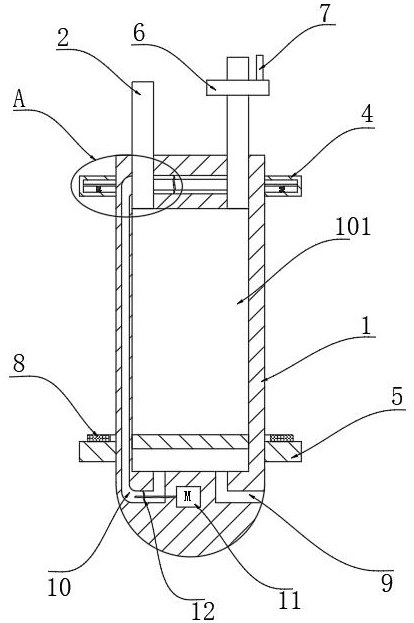

[0025] refer to Figure 1-4 , an oil supply detection device for a marine lifeboat engine, comprising a columnar oil supply tank 1, the oil supply tank 1 is installed on the lower side of the lifeboat, and the oil supply tank 1 is submerged in water when the ship is working, and the oil supply tank 1 is hollow structure and its upper end is connected with oil inlet pipe 2 and oil delivery pipe 3, and the lower ends of oil inlet pipe 2 and oil delivery pipe 3 are equipped with check valves, and the check valve at oil inlet pipe 2 allows liquid to flow from oil inlet pipe 2 to oil supply in one direction. In the tank 1, the one-way valve at the oil delivery pipe 3 allows the liquid to flow from the oil supply tank 1 to the oil inlet pipe 2 in one direction. 1. When the oil pressure at the oil inlet end of the engine is insufficient, the oil can be pumped from the oil inlet pipe 2 and then pumped to the oil inlet end of the engine through the oil delivery pipe 3, so as to ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com