A pump and hydraulic power assembly using the pump

A hydraulic power and assembly technology, applied to liquid fuel engines, pumps, pump components, etc., can solve the problems of increasing the starting load of the motor, large starting load, and large motor loss, and achieve the effect of reducing the starting load and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

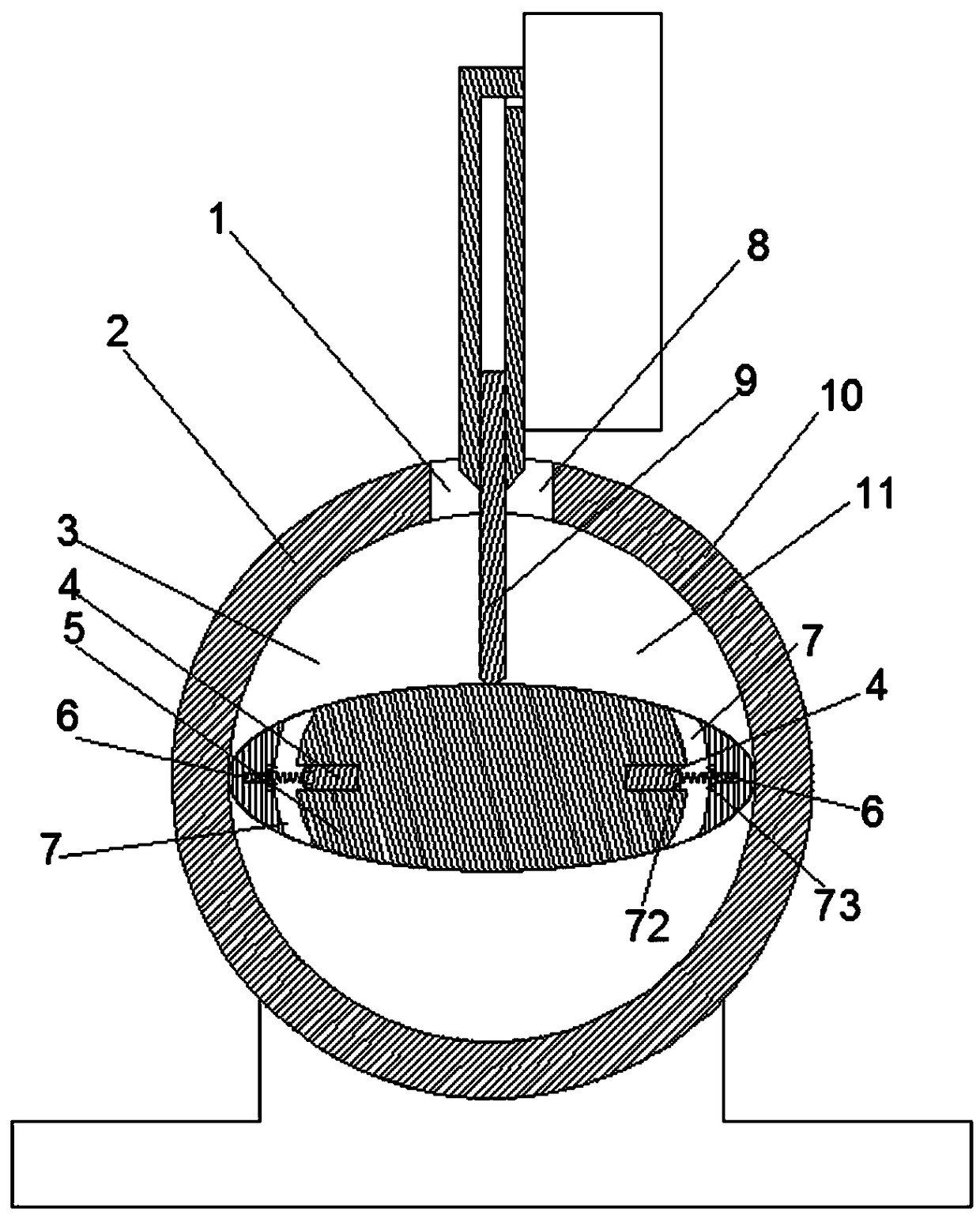

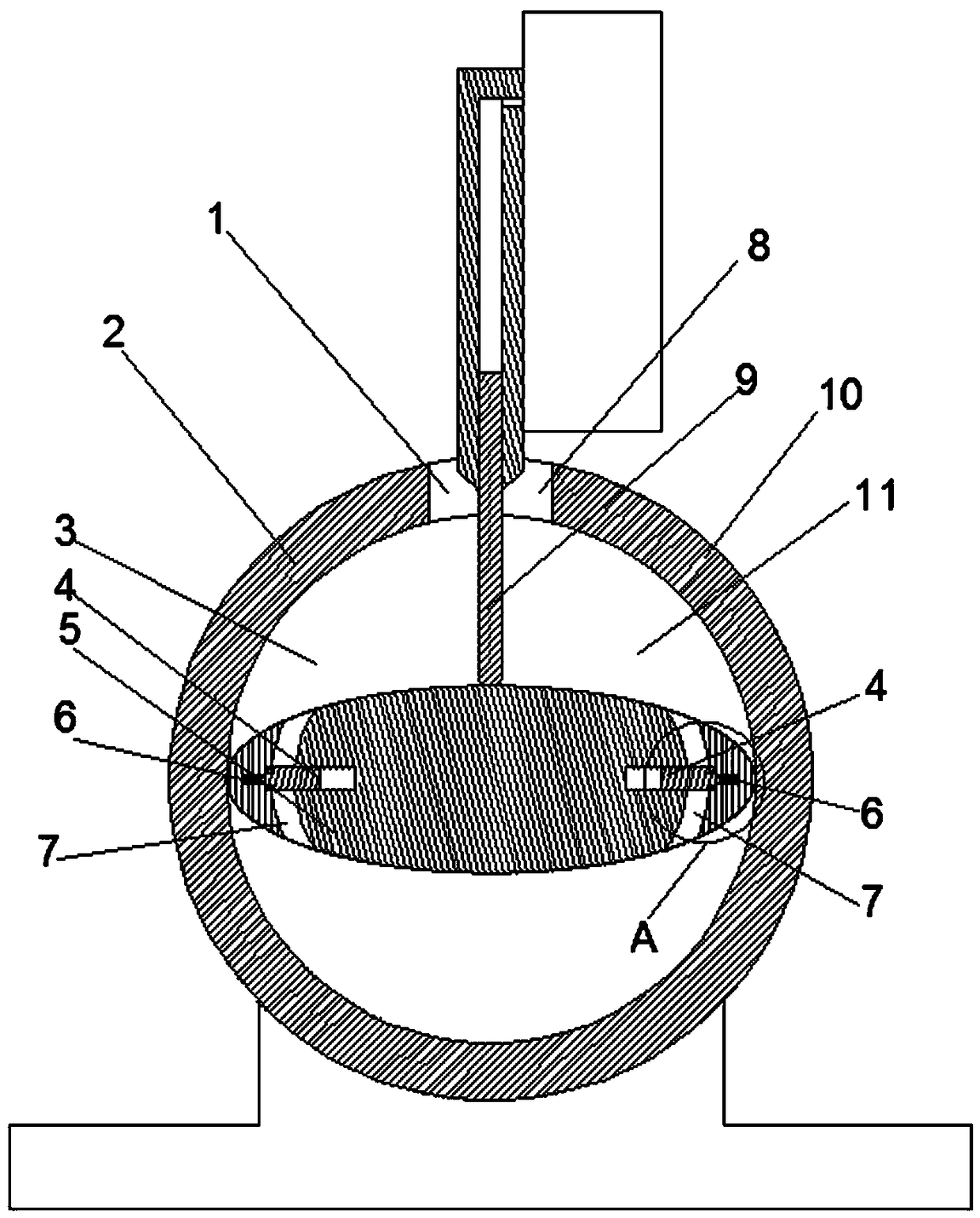

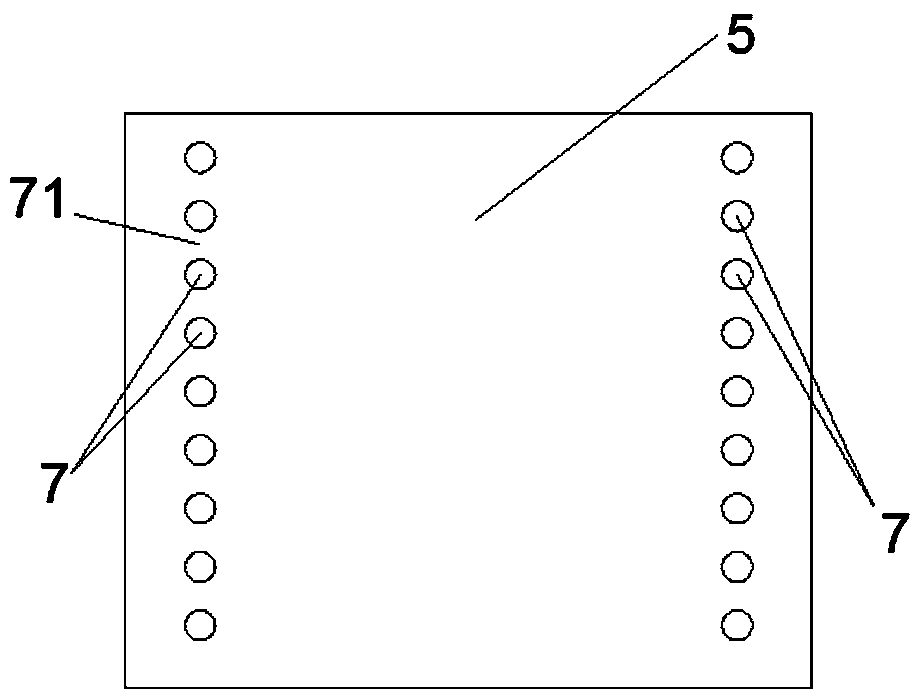

[0021] Examples of hydraulic powertrains in the present invention are Figure 1~9 Shown: includes motor 37 and pump 36, and pump 36 comprises the pump body 2 that has cylindrical hole inner chamber, is provided with the rotor 5 that rotation axis extends along the front-back direction, and cross-section is ellipse in the pump body 2, and the rotor 5 There are two tangent points between the cross section and the cylindrical inner hole. There is a hole on the pump body, and the guiding movement assembly at the hole has one end that slides and pushes with the outer peripheral surface of the rotor to separate the hole into a liquid inlet 8 and a liquid outlet. The partition 9 of 1, the inner cavity of the cylindrical hole is also separated by the partition 9 into a low-pressure chamber 11 communicating with the liquid inlet 8 and a high-pressure chamber 3 communicating with the liquid outlet 1, and the two ends of the rotor in the long diameter direction are provided with communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com