Rapid waste paper soaking device for recycled paper

A technology of recycled paper and waste paper, applied in paper recycling, recycling technology, raw material separation, etc., can solve the problems of accelerating paper soaking, failing to achieve uniform separation of paper, and ineffective effects, and achieve the effect of accelerating paper soaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

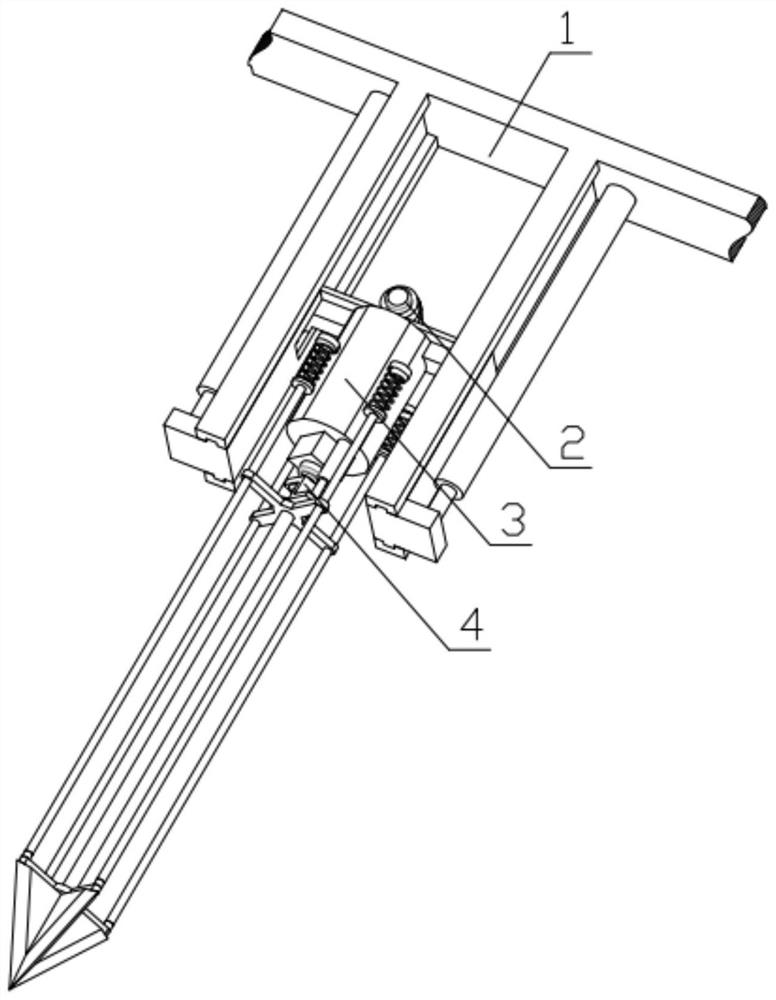

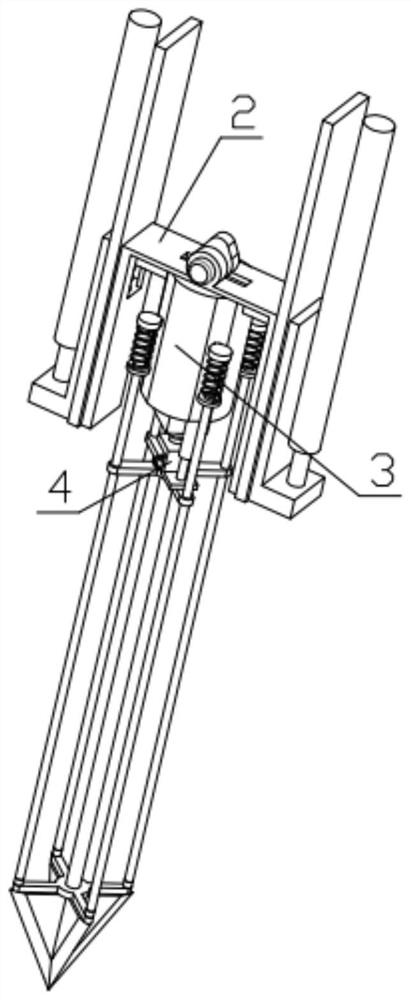

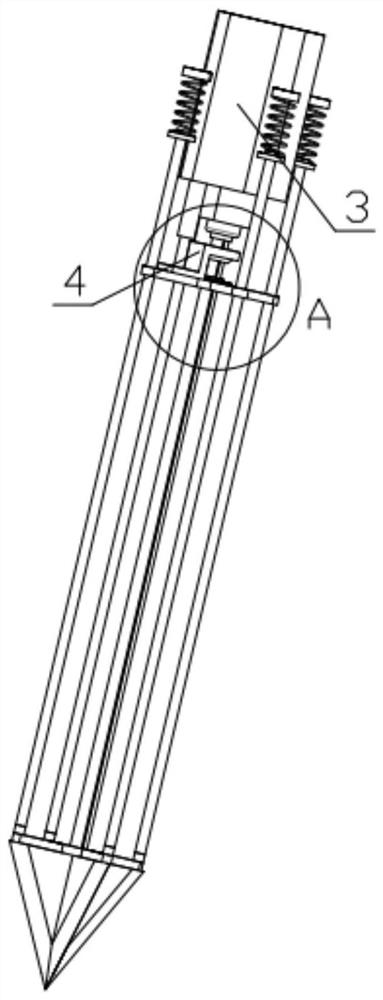

[0032] Combine below Figure 1-14 Describe this embodiment, a waste paper rapid soaking device for recycled paper, including a top connection and fixing plate 1, a shaking mechanism 2, a cross-shaped penetration mechanism 3 and a rotation adjustment mechanism 4, and the shaking mechanism 2 is fixedly installed on the top connection and fixed On the plate 1, the shaking mechanism 2 is slidably installed in the groove provided on the top connecting fixed plate 1, the cross-shaped penetrating mechanism 3 is fixedly installed on the shaking mechanism 2, and the rotation adjustment mechanism 4 is fixedly installed on the cross-flower penetrating mechanism 3. The adjustment mechanism 4 is slidably installed on the criss-cross mechanism 3 .

specific Embodiment approach 2

[0033] Combine below Figure 1-14 This embodiment will be described. This embodiment will further explain the first embodiment. The shaking mechanism 2 includes a lifting hydraulic cylinder 2-1, a connecting frame 2-2, a shaking motor 2-3, a cam 2-4, and a sliding block 2- 5. The support spring 2-6, the lifting hydraulic cylinder 2-1 is fixedly installed on the top connecting fixed plate 1, the output end of the lifting hydraulic cylinder 2-1 is fixedly installed with a connecting frame 2-2, and the connecting frame 2-2 is slidably installed on the In the groove provided on the top connecting fixed plate 1, the shaking motor 2-3 is fixedly equipped with a connecting frame 2-2, the output end of the shaking motor 2-3 is fixedly installed with a cam 2-4, and one end of a support spring 2-6 Fixedly installed in the groove provided on the connecting frame 2-2, the other end of the support spring 2-6 is fixedly installed with a sliding block 2-5, and the sliding block 2-5 is slidab...

specific Embodiment approach 3

[0034]Combine below Figure 1-14 Describe this embodiment, this embodiment will further explain the second embodiment, the cross-shaped penetrating mechanism 3 includes a shell 3-1, a rotating disk 3-2, a tension spring 3-3, a ring 3-4, Thin steel bar 3-5, rotating motor 3-6, band grooved connecting rod 3-7, rotating head piece 3-8, cross flower plate 3-9, cross flower carving knife 3-10, the concave that is set on the shell 3-1 Rotating disc 3-2 is installed in the groove, and tension spring 3-3 is fixedly installed on the rotating disc 3-2, and the other end of tension spring 3-3 is fixedly equipped with ring 3-4, ring 3 Thin steel bar 3-5 is slidably installed in the through hole of -4, and the other end of thin steel bar 3-5 is fixedly installed with rotating head piece 3-8, and the rotating head piece 3-8 is rotatably installed on the cross flower board 3-9 to set In the groove, the cross flower plate 3-9 is fixedly installed with a cross flower carving knife 3-10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com