System for cooking purified cottons

A processing system and technology for refined cotton, which are applied in the processing of fiber raw materials, pretreatment with alkaline compounds, washing/replacement of pulp treatment liquid, etc. problems, to achieve the effect of continuous and rapid alkali cleaning, improve production efficiency and improve the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

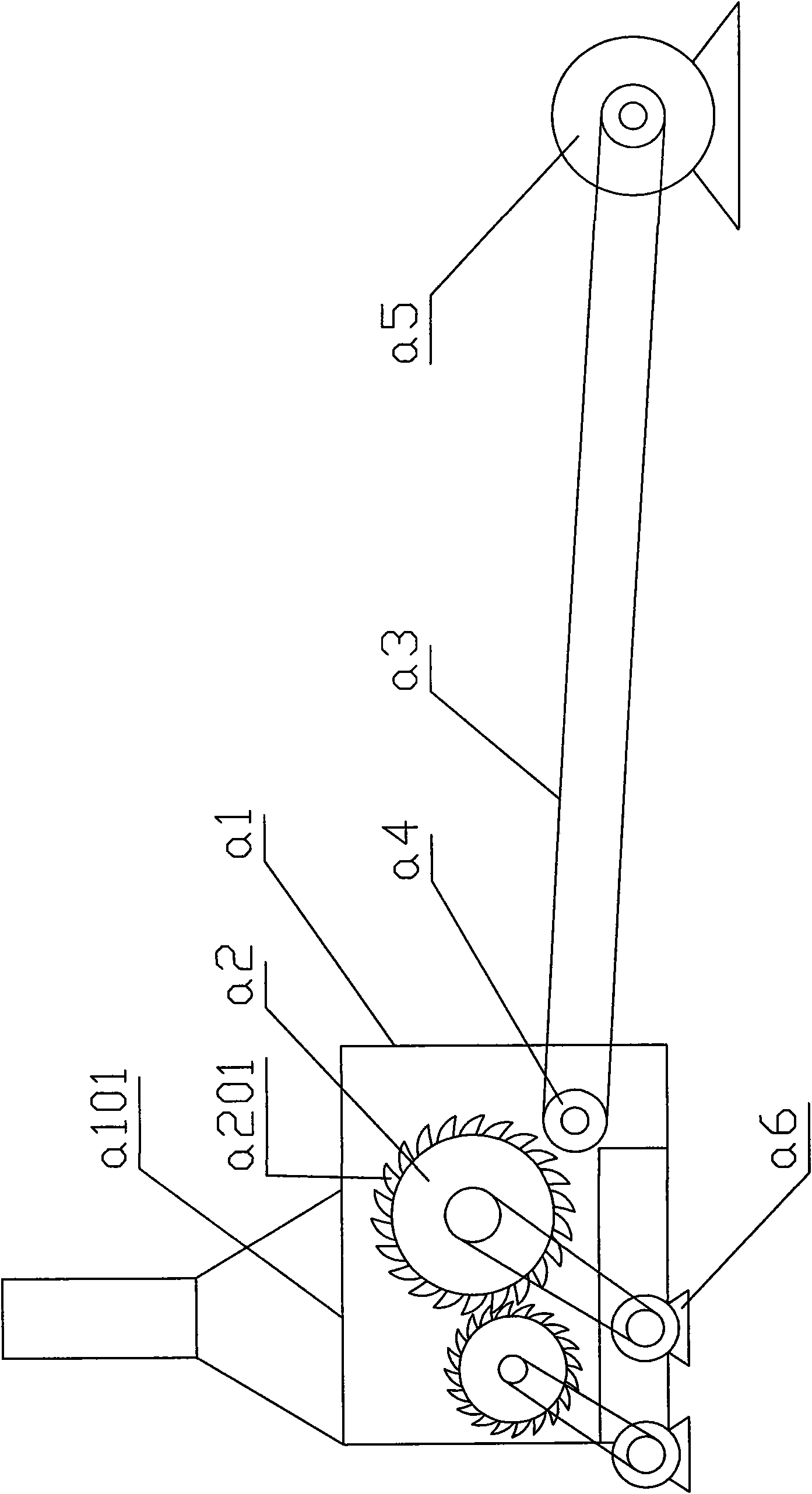

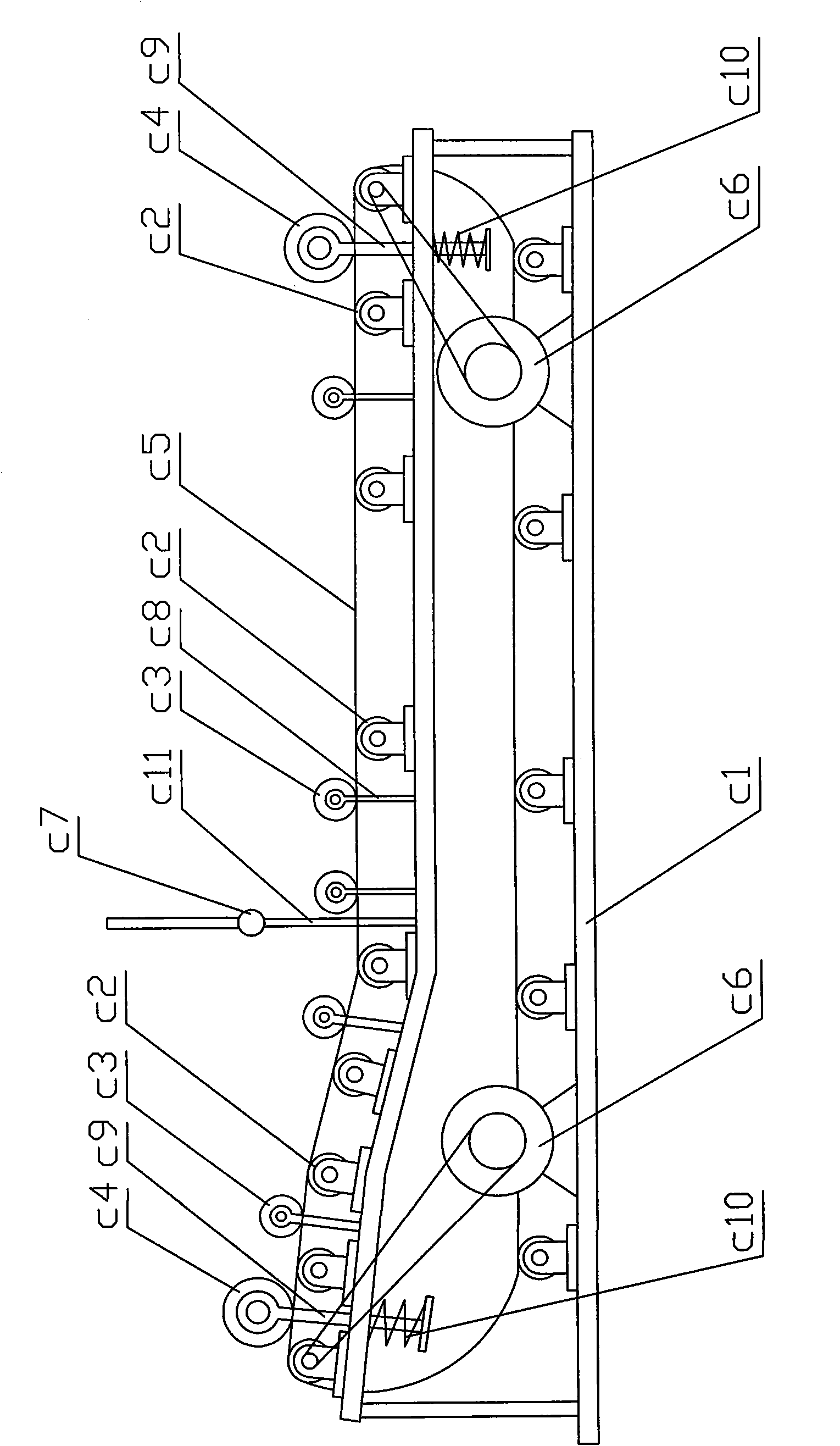

[0016] Depend on figure 1 , figure 2 and image 3 As shown, the refined cotton cooking treatment system is mainly composed of a refined cotton cooking pre-cooking vegetable pine impurity removal device, a refined cotton pre-cooking pre-soda soaking device and a refined cotton cooking multi-stage alkali cleaning device. , including the shell a1, the tearing rollers a2 installed in pairs in the shell a1, the transmission belt a3, the transmission roller a4 and the transmission motor a5, the transmission belt a3 is tightly wound on the transmission roller a4, the transmission motor a5 is connected to the transmission roller a4, The front end of the conveyor belt a3 is located below the tearing roller a2 in the casing a1, and the tearing roller a2 is connected to the motor a6 through transmission. The surface of the tearing roller a2 is provided with teeth a201, and the casing a1 is provided with a cotton hole a101. In order to increase the tearing effect, Preferably, the teari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com