Drying device for child garment processing

A technology for drying devices and children's clothing, applied in washing devices, laundry room devices, applications, etc., can solve the problems of clothing deformation, long processing time, and many wrinkles, so as to reduce the generation of wrinkles, improve processing efficiency, and promote drying and dehumidification. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

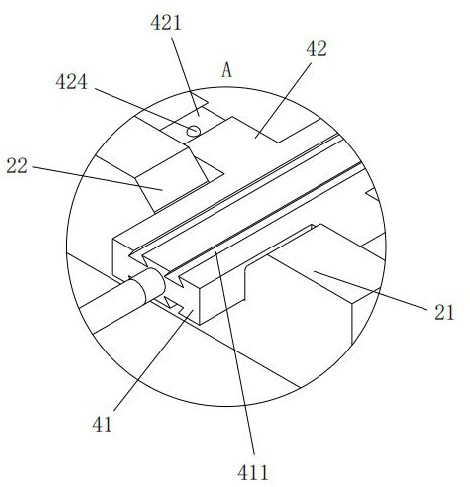

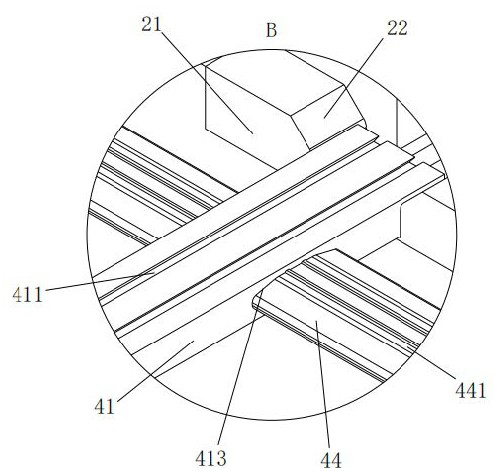

[0037] As a specific embodiment of the present invention, the upper and lower surfaces of the main rod 41 are evenly provided with No. 1 drainage groove 411, the upper and lower surfaces of the support rod 42 are evenly provided with No. 2 drainage groove 421, and the upper and lower surfaces of the wing plate 44 are evenly arranged. There is No. 3 drainage tank 441;

[0038] The first drainage groove 411, the second drainage groove 421 and the third drainage groove 441 are all tapered grooves.

[0039] During work, during the ironing process, the end of the main rod 41 is exposed to the outside of the coat, so that the outside air can enter the inside of the coat along the No. Flow in the gap between pole 42 and the inner surface of the coat, the flowing air-flow accelerates the evaporation of moisture, and promotes the moisture to be recovered from the coat along with the flowing air-flow; The gap between the sheets increases, and the guiding effect of the No. 1 drainage gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com