Mixed powder for additive manufacturing and preparation method thereof

A technology of additive manufacturing and powder mixing, which is applied in the field of additive manufacturing and can solve the problems of uneven composition and inapplicability of forming and forming samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

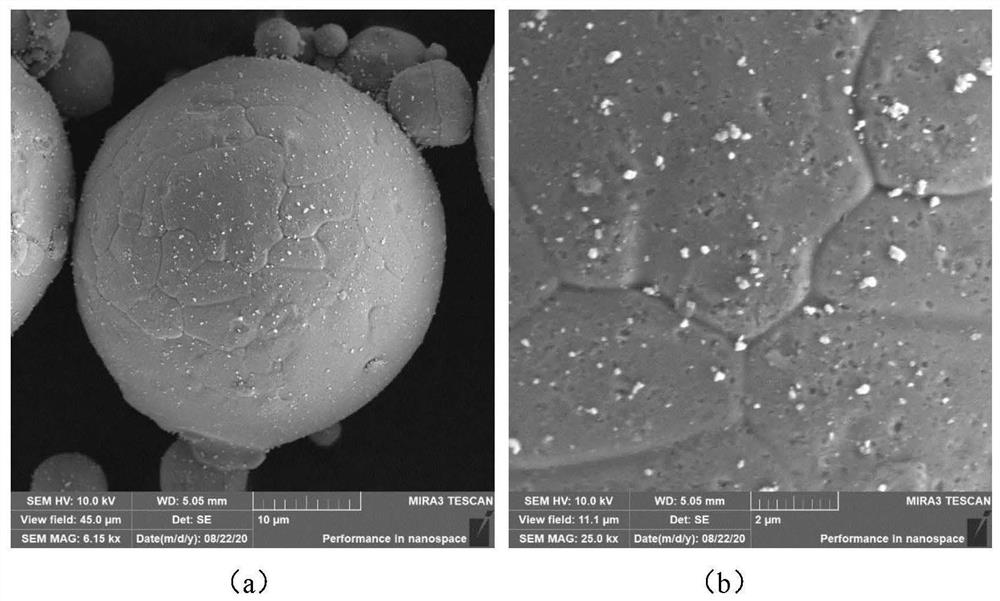

Embodiment 1

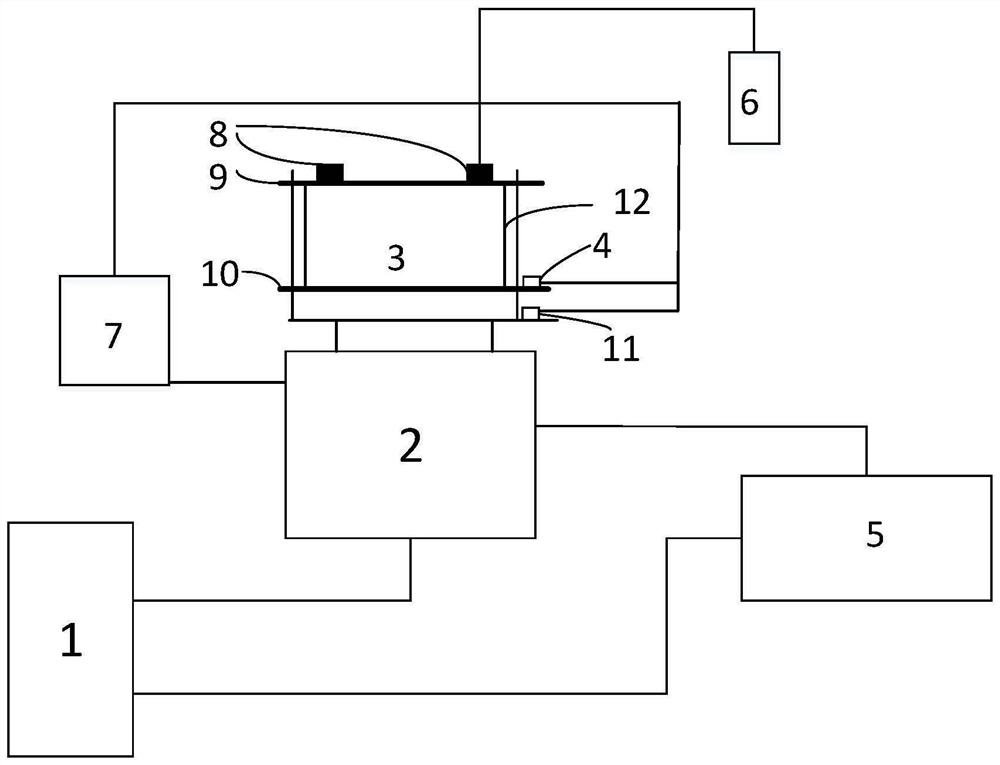

[0055] 1. Installation: first pour a certain amount of WC into the powder mixing container 3, then pour about 1Kg of CoCrFeNi high-entropy alloy powder into the powder mixing container 3, cover the WC powder to prevent the WC from being blown away, and put the mixing The powder container 3 is placed above the vibrating table body 2. It is required to align the screw holes of the bottom plate 10 with the nut holes above the vibrating table body 2, cover the Al alloy cover plate 9, and pass 8 bolts through the 2 Al alloy covers. The screw holes of the plate 9 are screwed into the nuts of the vibrating table body 2, and the screws are tightened to completely fix the upper cover plate 9, the powder mixing container 3 and the vibrating table body 2 together.

[0056] 2. Air washing: Open all the two quick plugs 8. Turn on the switch at the argon decompression valve of the argon source 6, adjust the flow rate of the argon gas until the flow rate is 10-30cm 3 / min, connect the argon...

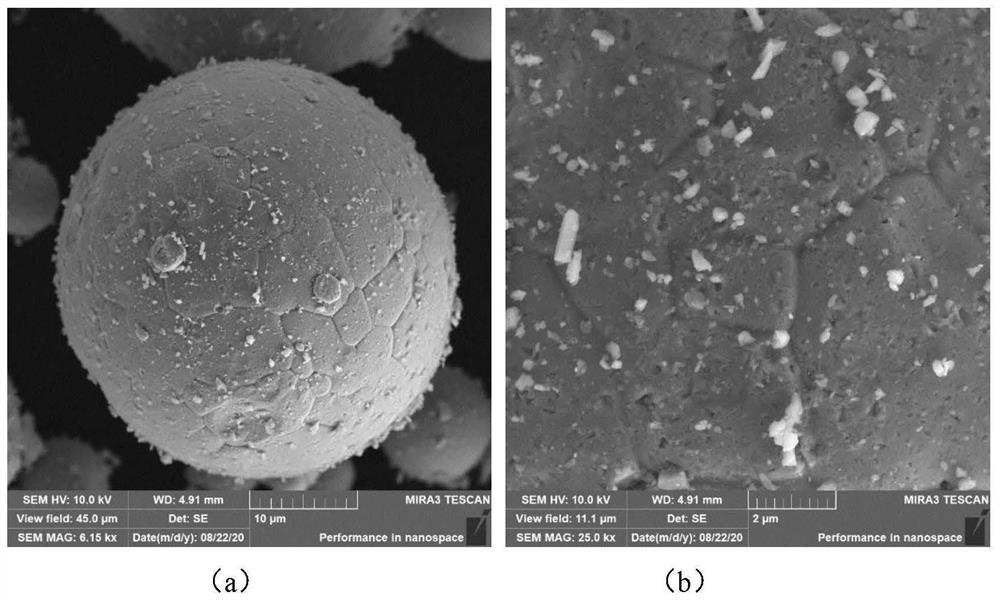

Embodiment 2

[0063]1. Installation: first pour a certain quality of TiC into the powder mixing container 3, then pour about 1Kg of CoCrFeNi high-entropy alloy powder into the powder mixing container 3, cover the TiC powder to prevent the TiC from being blown away, and put the The powder container 3 is placed above the vibrating table body 2. It is required to align the screw holes of the bottom plate 10 with the nut holes above the vibrating table body 2, cover the Al alloy cover plate 9, and pass 8 bolts through the 2 Al alloy covers. The screw holes of the plate 9 are screwed into the nuts of the vibrating table body 2, and the screws are tightened to completely fix the upper cover plate 9, the powder mixing container 3 and the vibrating table body 2 together.

[0064] 2. Air washing: Open all the two quick plugs 8. Turn on the switch at the argon decompression valve of the argon source 6, adjust the flow rate of the argon gas, and when the flow rate is 10-30 cm3 / min, connect the argon g...

Embodiment 3

[0071] 1. Installation: First put a certain quality of Y 2 o 3 Pour into the powder mixing container 3, then pour about 1Kg of CoCrFeNi high-entropy alloy powder into the powder mixing container 3, and cover Y 2 o 3 powder, to prevent Y2O3 from being blown away, place the powder mixing container 3 on the top of the vibrating table body 2, align the screw holes of the bottom plate 10 with the nut holes on the top of the vibrating table body 2, cover the Al alloy cover plate 9, and put 8 bolts pass through the screw holes of the two Al alloy cover plates 9, screw them into the nuts of the vibrating table body 2, tighten the screws, and completely fix the upper cover plate 9, the powder mixing container 3 and the vibrating table body 2 together .

[0072] 2. Air washing: Open all the two quick plugs 8. Turn on the switch at the argon decompression valve of the argon source 6, adjust the flow rate of the argon gas, and when the flow rate is 10-30 cm3 / min, connect the argon gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com