Five-axis machine tool rotary table with damping structure

A technology for machine tools and turntables, applied in the field of CNC machine tools, can solve the problems of lowering the accuracy of the turntable, affecting the machining accuracy of parts, affecting the processing quality, etc., and achieving the effect of preventing deformation and preventing rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to achieve the above purpose and effects, the technical means and structures adopted in the present invention will be described in detail in terms of the features and functions of the preferred embodiments of the present invention in conjunction with the accompanying drawings.

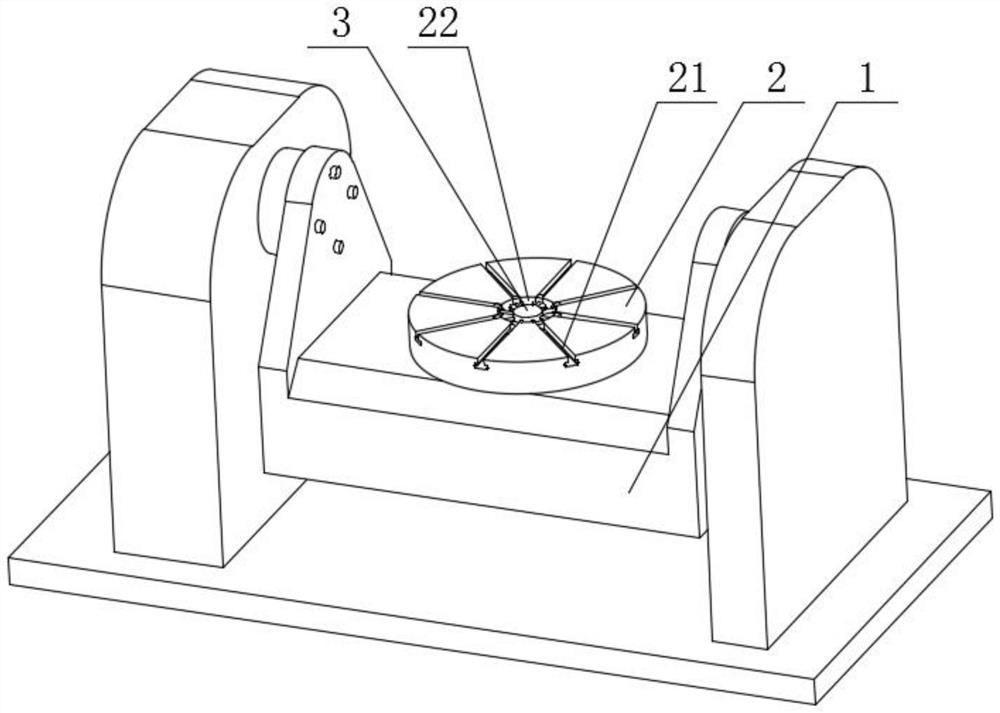

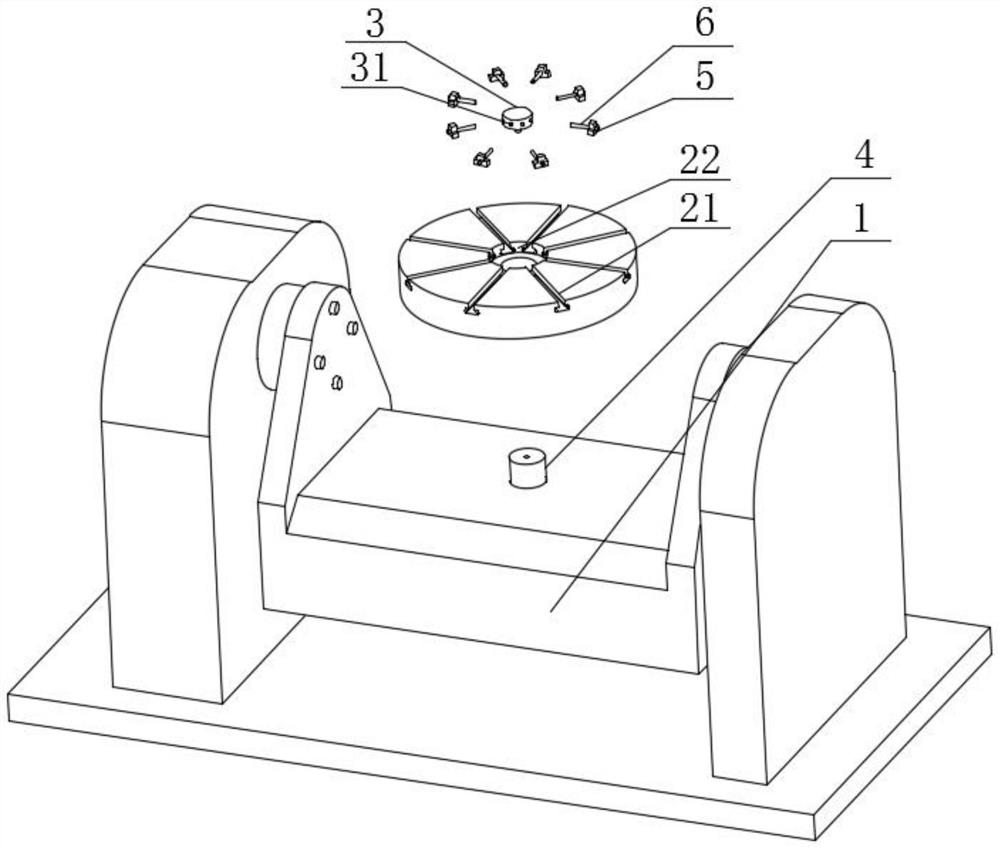

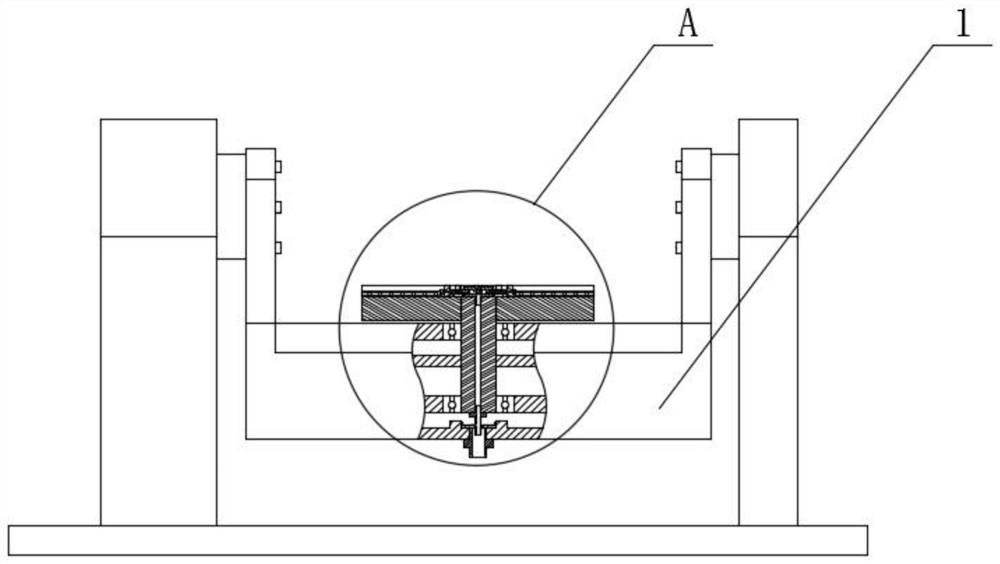

[0020] Such as Figure 1-4 As shown, the present invention provides a five-axis machine tool turntable with a shock-absorbing structure, including a turntable main body 1, a rotary table 2 is provided on the rotary table main body 1, and a depression is provided at the center of the upper part of the rotary table 2 part 22, a plurality of T-shaped slots 21 extending to the outside of the rotary table 2 are evenly provided around the recessed part 22; the T-shaped slots 21 are used for fixing bolts and parts or fixtures; the center of the rotary table 2 A rotating shaft 4 is connected; the rotating shaft 4 is connected to the main body 1 of the turntable through a bearing 7; the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com