Mold set for a ski press

A technology for skis and presses, applied in the directions of skis, presses, manufacturing tools, etc., can solve the problems of putting in, unable to achieve temperature adjustment, and long cycle time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

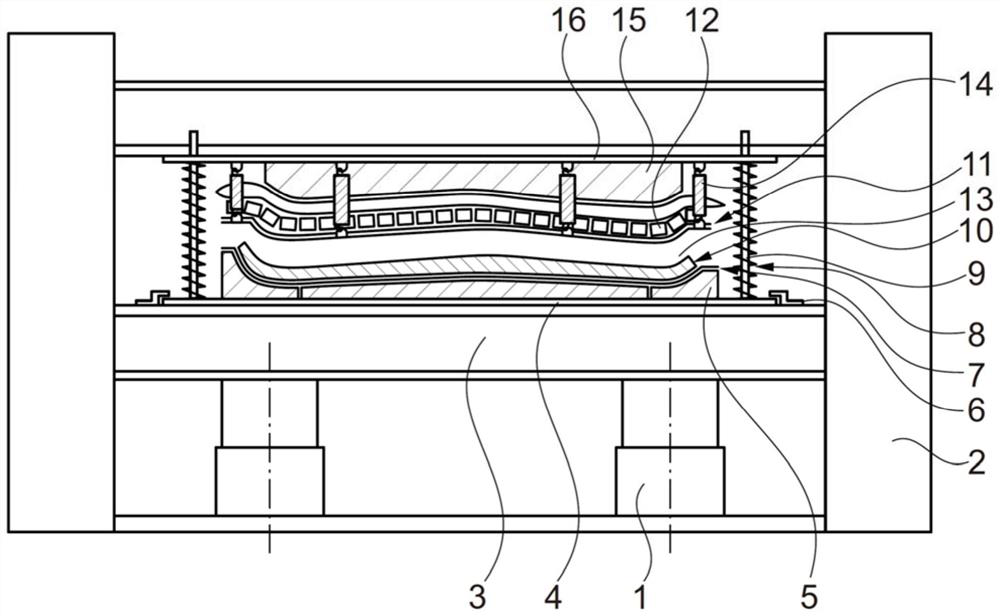

[0041] The idea is realized with a system of a ski press 2 which, by means of a reciprocating piston 1 , moves a pressure beam 3 relative to a fixed beam and thereby applies pressure. Alternatively, the pressure can also be generated by other known methods, such as pressure hoses. A novel system consisting of a unit consisting of mold superstructure and substructure, heating planes and the actual snowboard moulds is put into the press.

[0042] exist figure 1 The mold block in the snowboard press 2 is shown in . These individual components are the reciprocating piston of the press 1, the ski press 2, the pressure beam 3 of the press, the base plate 4 of the mold block, the lower profile 5 of the mold block, the positioning aid 6, the lower heating element 7, the compression spring 8 , vertical beams 9, aluminum ski molds 10, upper heating elements 11, steel profiles for pressure distribution 12, elastic compensating elements 13, tension springs 14 holding open around the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com