Guiding plate, loom heald frame, and guiding plate and loom heald frame mounting method

A technology of guide plates and heald frames, which is applied in textiles, healds, textiles and papermaking, etc. It can solve the problems of inconvenient replacement of guide plates, risks of guide plates and heald frames, and wear of guide plates, and achieves fast and convenient installation methods. The effect of saving equipment time and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

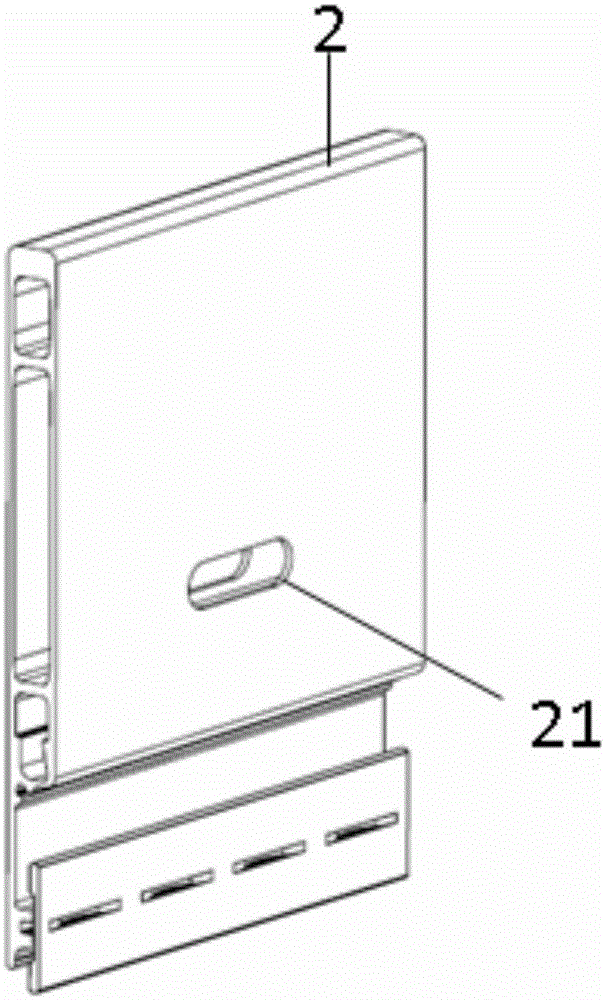

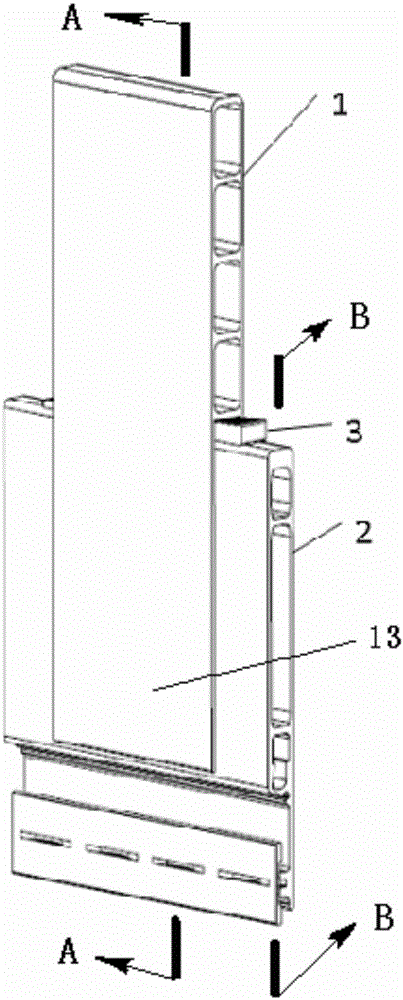

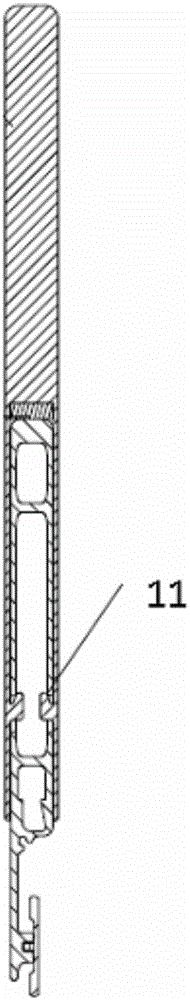

[0036] A guide plate 1, the guide plate 1 is provided with two side plate legs 13, each of the side plate legs 13 is provided with a protruding hook structure 11. The hook structure 11 is provided with an inclined surface. The inclined surface can make the side plate legs 13 closely fit on the heald frame beam 2 . The hook structure 11 is matched with the long opening of the heald frame beam 2 .

[0037] A loom heald frame, the loom heald frame includes a guide plate 1, a heald frame beam 2, and the loom heald frame also includes a wedge-shaped block 3 for fixing the guide plate 1 and the heald frame beam 2, the The wedge block 3 is fixed between the top of the heald frame beam 2 and the guide plate, the heald frame beam 2 has a first long opening 21, and the guide plate 1 is provided with two side plate legs 13, each of which A protruding hook-shaped structure 11 is arranged on each of the side plate legs, and the hook-shaped structure 11 is matched with the long opening 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com