Carbon fiber manufacturing method

a carbon fiber and manufacturing method technology, applied in the field of carbon fiber manufacturing technique, can solve the problems of inability to achieve the purpose of protecting the fiber, inability to fully bond the fiber and the resin oiling agent in the sizing step, and excessive fineness of the carbon fiber surface, so as to reduce the cost of carbon fiber production equipment and the working time. , the structure of the carbon fiber is more stable and reliable, and the effect of improving the stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]Embodiments of the present invention will now be described, by way of example only, with reference to the accompanying drawings.

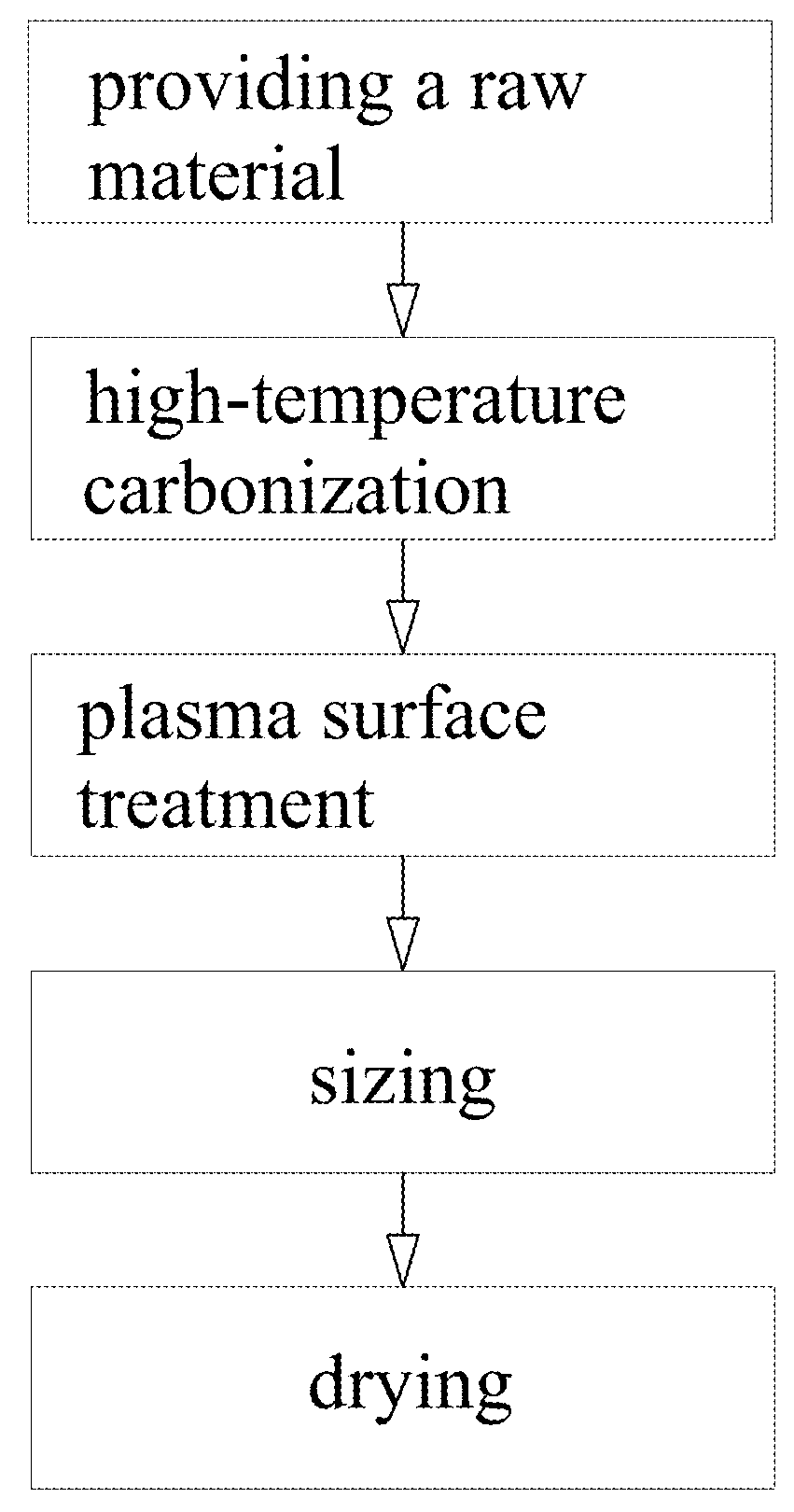

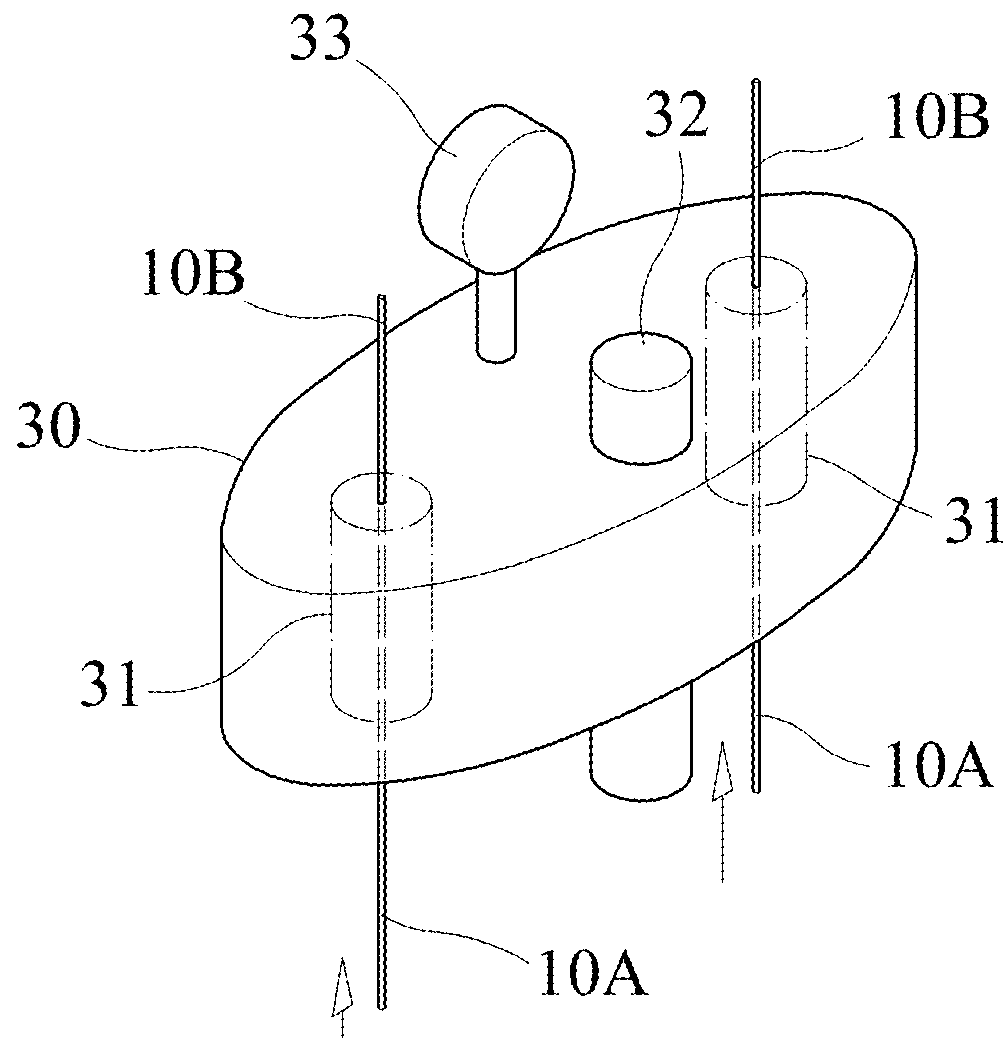

[0038]The present invention discloses a carbon fiber manufacturing method which can greatly improve the sizing quality of carbon fibers and effectively reduce the cost of the carbon fiber production equipment and the working time. As shown in FIG. 1, the carbon fiber manufacturing method of the present invention comprises providing a raw material step, performing a high-temperature carbonization step, performing a plasma surface treatment step, and performing a sizing step. The carbon fiber manufacturing method further comprises performing a drying step after the sizing step. Referring to FIG. 1 through FIG. 5, the steps are described in details as below.

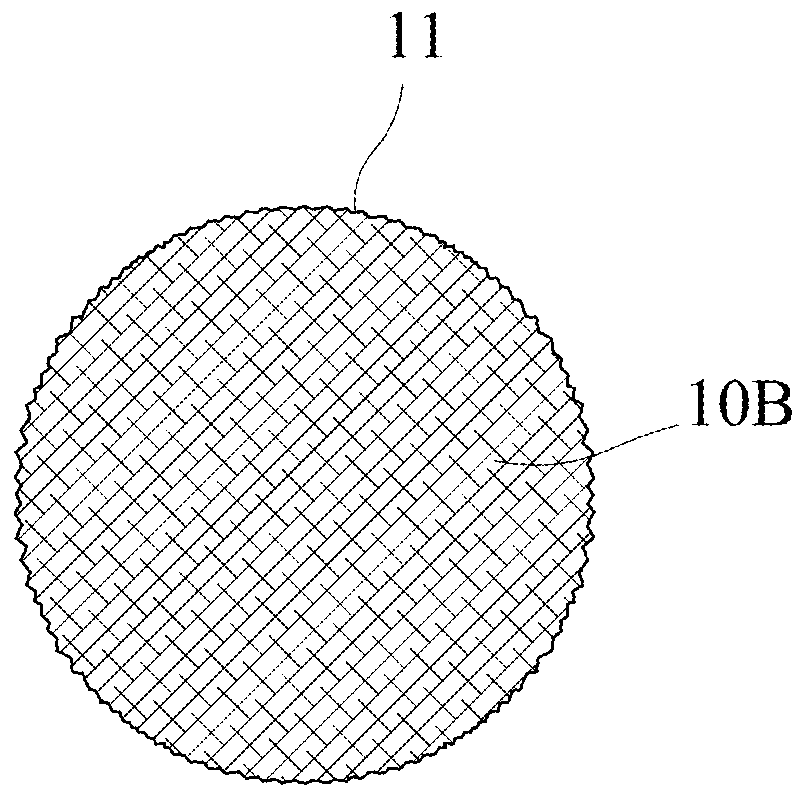

[0039]In the step of providing the raw material, a carbon fiber precursor fiber bundle 10A is provided to be processed to form a carbon fiber 10B. In practice, the carbon fiber precursor fiber bundle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power density | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com