Remote dismounting device and process for bead stringing rope of diamond rope sawing machine

A diamond wire saw machine and dismantling device technology, which is applied in the direction of sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of large radiation risks for workers, complicated tool disassembly and assembly methods, and inconvenient operation, etc., to achieve The effect of reducing the risk of radiation exposure, improving the convenience of operation, and increasing the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

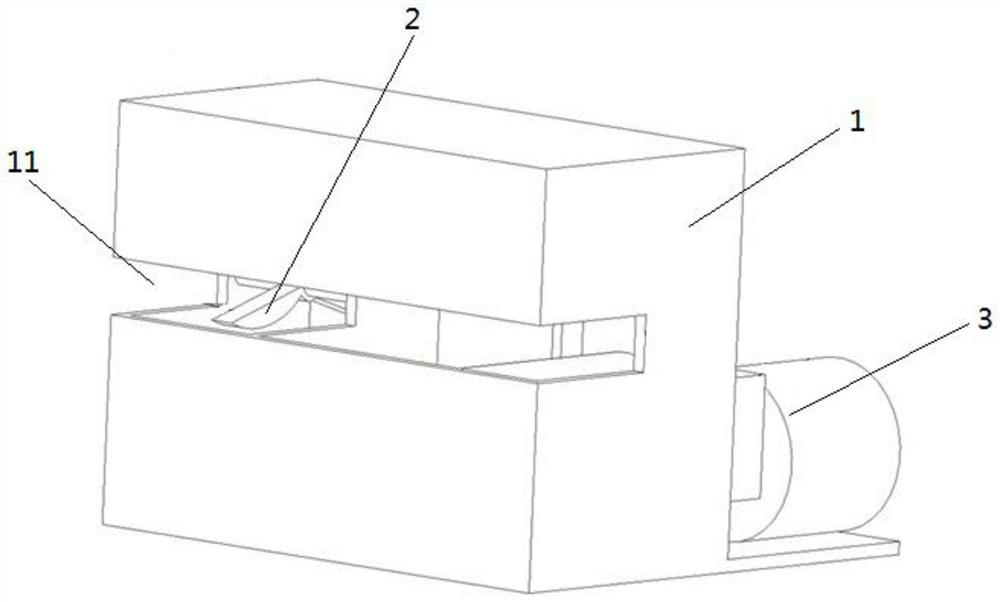

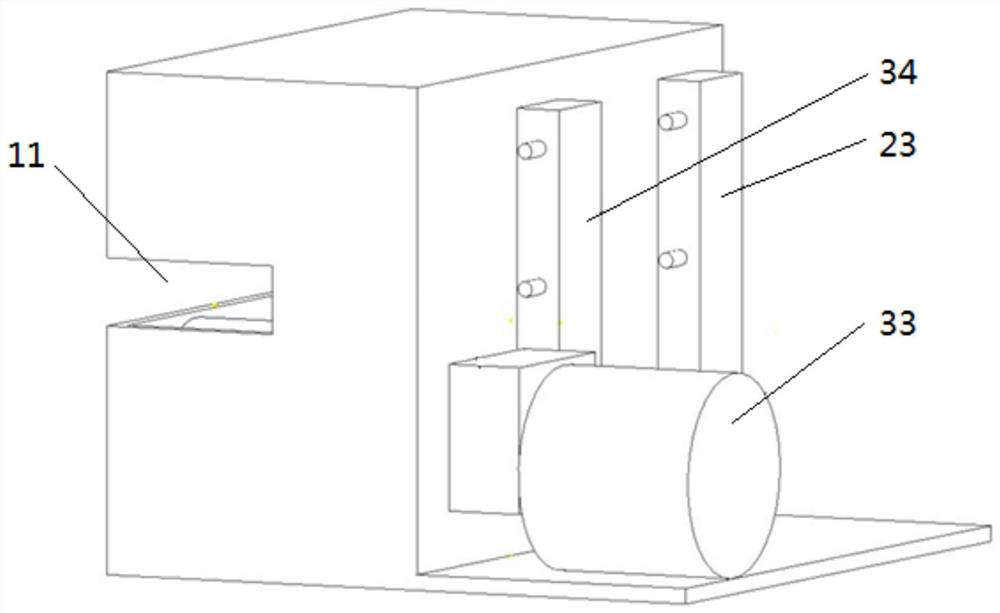

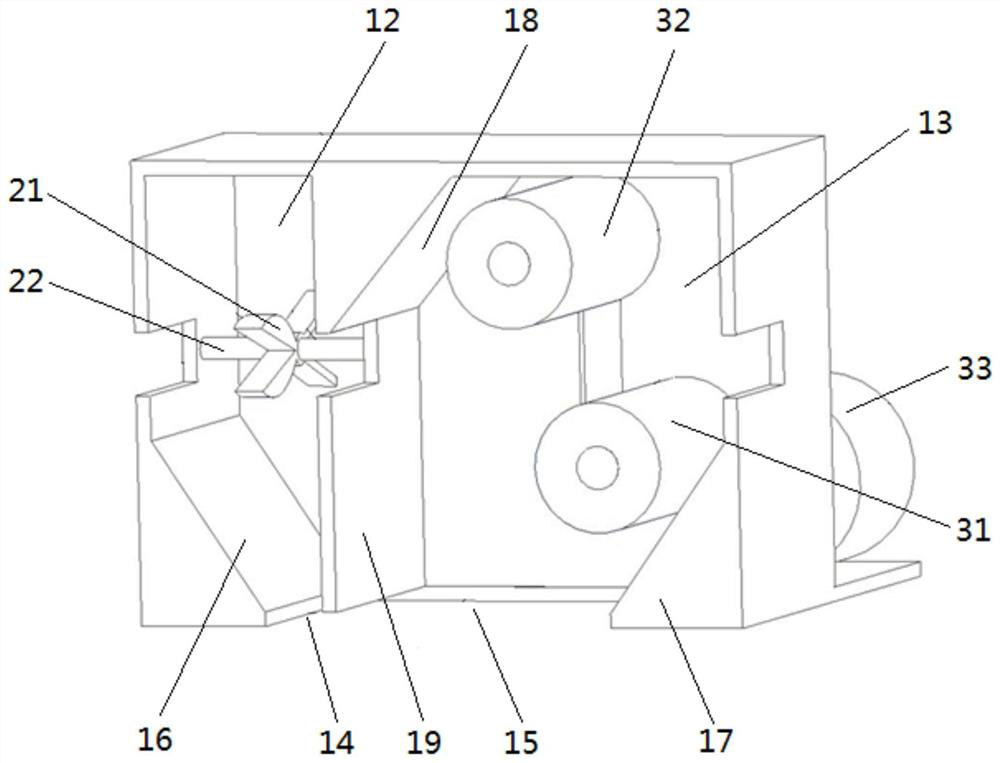

[0029] see Figure 1 ~ Figure 3 , the remote disassembly device for the beaded rope of a diamond wire saw machine provided in this embodiment can not only be applied in the air environment, but also can be applied in the underwater environment, or other areas where personnel are restricted, especially for radiation effects With a large space, it can realize the cutting and collecting operations of beaded rope or similar linear items. In this embodiment, the dismantling of the beaded rope used for cutting nuclear facilities is mainly taken as an example to expand the description.

[0030] The dismantling device includes a rope unloading frame 1 with a radiation-proof function. In this embodiment, the rope unloading frame 1 is a shell with an inner cavity. Except for the following necessary openings, other places are preferably sealed. Rope frame 1 also possesses basic anti-radiation function, for example, this unloading rope frame 1 adopts anti-radiation materials (such as met...

Embodiment 2

[0045] This embodiment also provides a remote disassembly process for the beaded rope of a diamond wire saw machine, mainly using the remote disassembly device for the beaded rope of a diamond wire saw machine described in Embodiment 1. The method includes:

[0046]S1: Insert the beaded rope into the card slot 11, so that the beaded rope runs through the front side wall of the rope unloading frame 1, the cutting space 12, the rope receiving space 13 and the rear side wall of the rope unloading frame 1 in sequence;

[0047] S2: Control the rope receiving mechanism 3 to position and clamp the beaded rope, and then control the cutting mechanism 2 to cut the beaded rope, the cut beaded rope has a free end, and then pull it through the rope receiving mechanism 3;

[0048] S3: Collect the cut beaded ropes, restore the initial state of the cutting mechanism 2 after the beaded ropes are collected, and wait for the next disassembly operation.

[0049] Through the above technical soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com