Flushing device for staining in pathology department

A flushing and pathological technology, applied in the field of pathological slice staining, can solve the problems of prolonged flushing time, slowed molecular motion, unsuitable control of water flow temperature, etc., and achieves the effect of constant water temperature and adjustable duration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] DETAILED DESCRIPTION OF THE DRAWINGS will be further described below. The same components are indicated by the same reference numerals. It should be noted that the words "front", "left", ",", ",", ",", ",", ",", ",", ",", ",", ",", ",", ",", "," "Refers to the direction towards or away from the specific component geometry.

[0031] In order to make the contents of the present invention more easily understood, the technical solutions in the embodiments in the embodiments will be described in contemplation in conjunction with the drawings in the embodiment of the present invention.

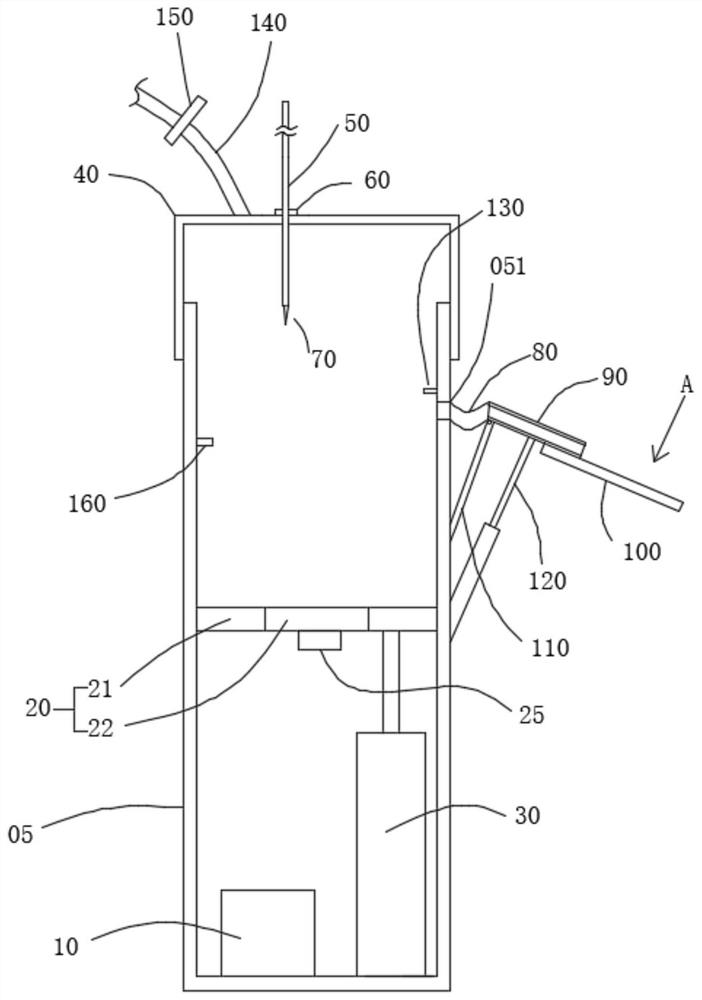

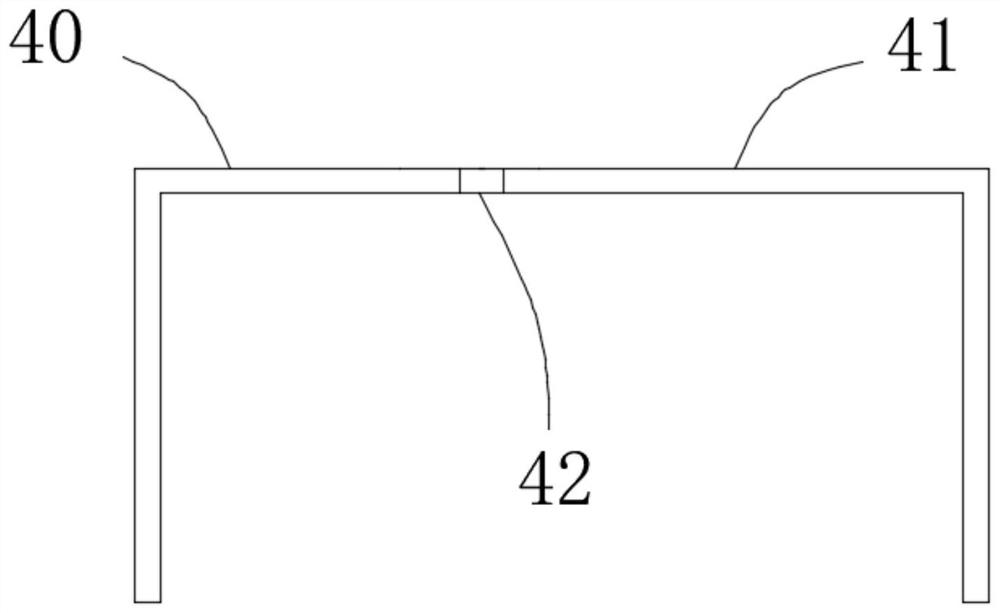

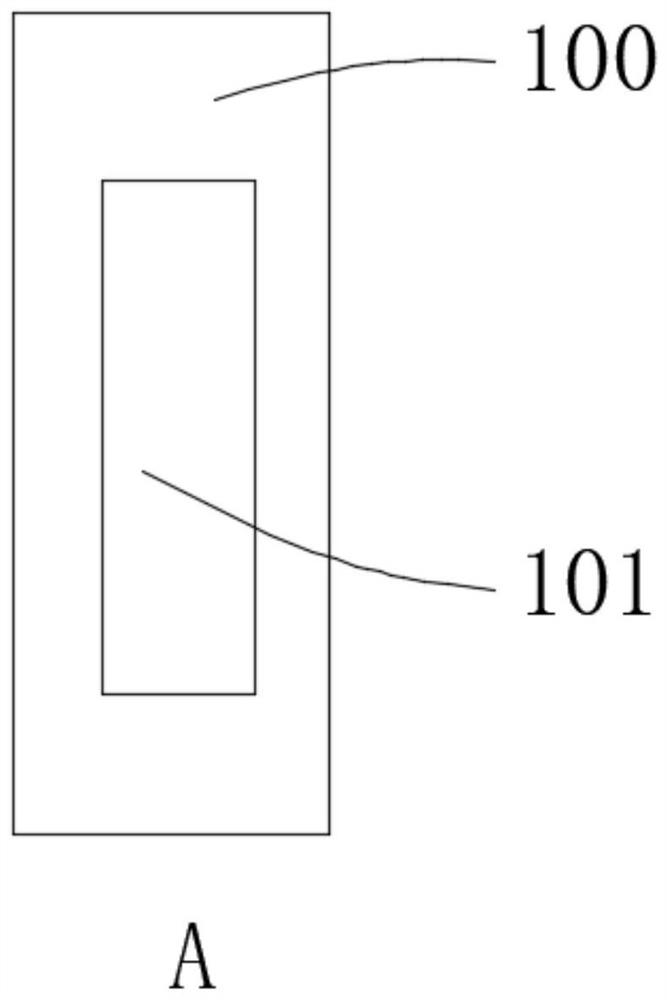

[0032] like Figure 1 to 4 As shown, a flushing device for dyeing a pathological branch, comprising a can body 05, a controller 10, a partition plate 20, a circle plate 21, a disc 22, a precipitation tank 23, a heating device 25, a telescopic cylinder 30, a can. The cover 40, the cover body 41, the via 42, the threaded rod 50, the nut 60, the liquid level sensor 70, the hose 80, the pipe 90, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com