Novel main tower crown structure and sectional installation method thereof

An installation method, the technology of the main tower, applied in the direction of towers, building types, buildings, etc., can solve the problems of heavy structure, high transportation cost, difficult weld quality, etc., to facilitate the control of installation accuracy, improve manufacturing accuracy and The effect of small mass, self-weight and geometric size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

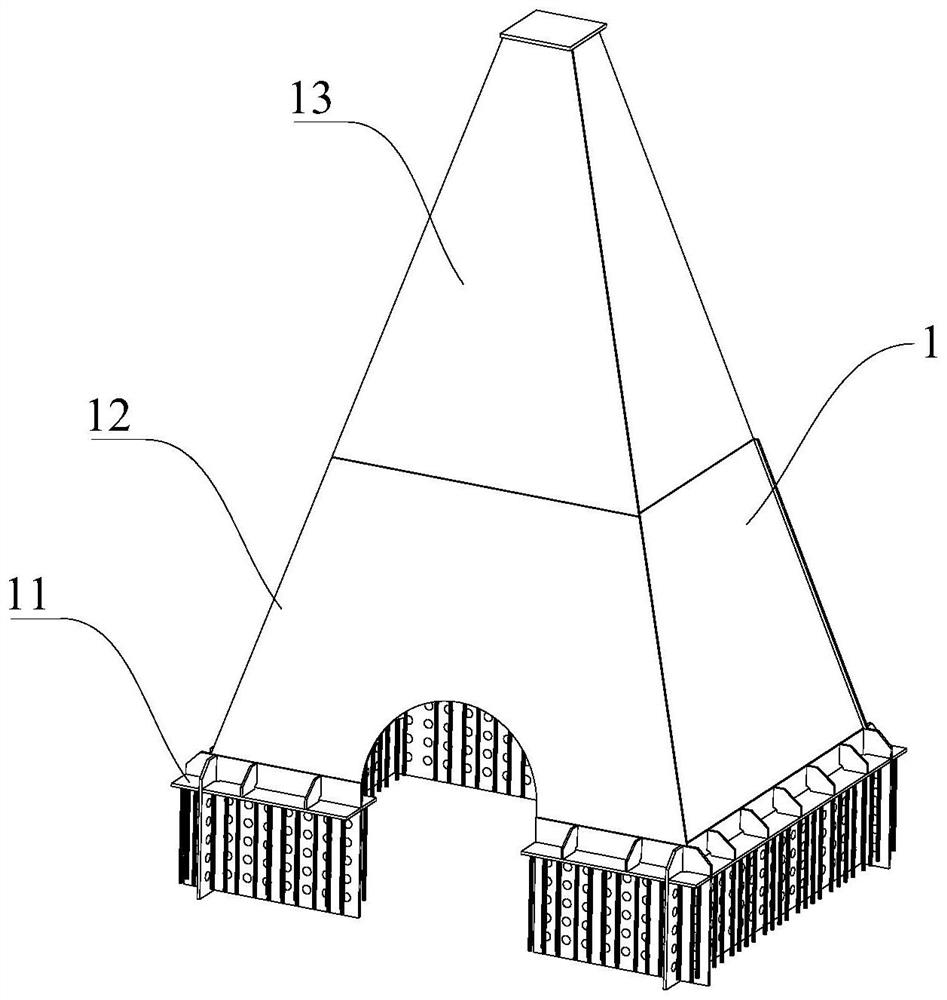

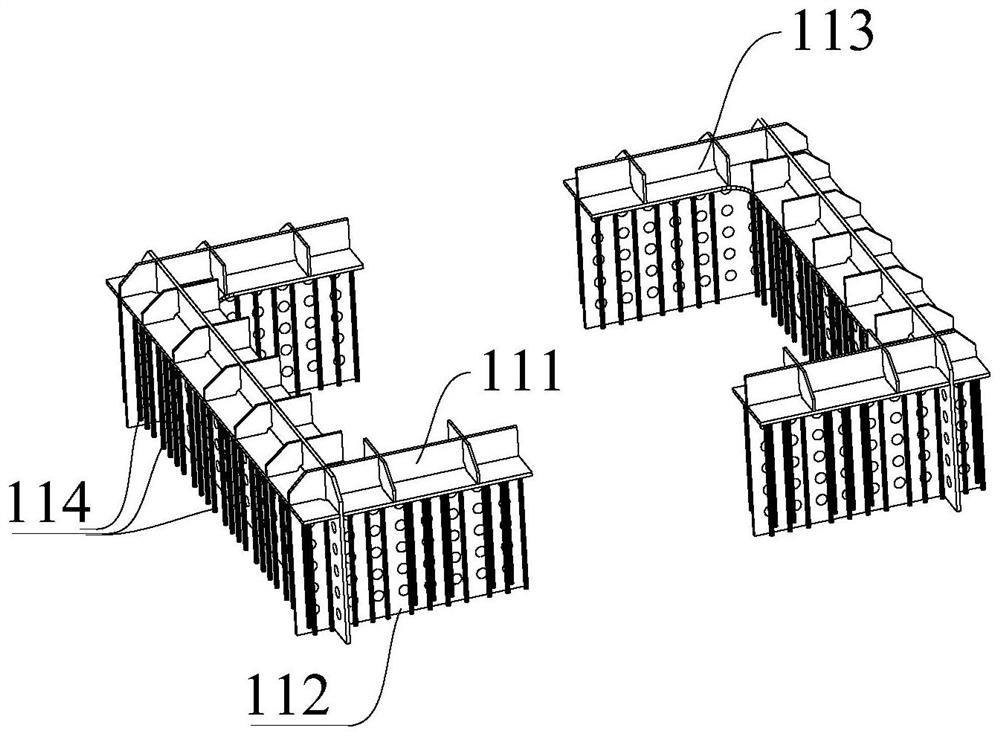

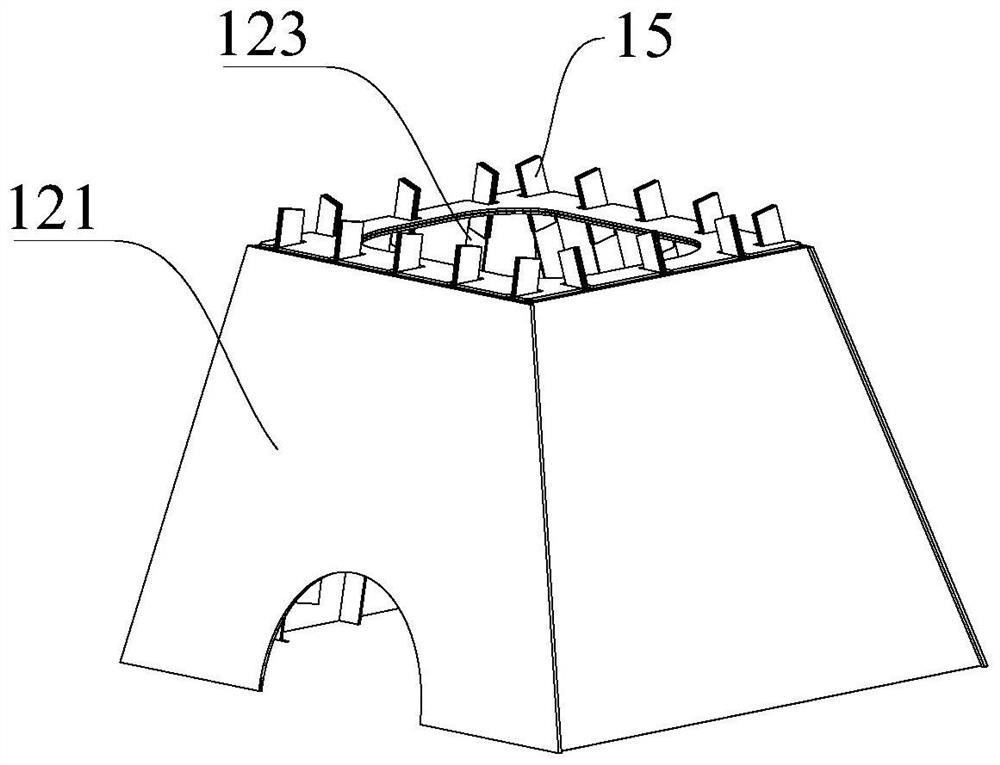

[0039] The crown structure of the main tower was originally designed as a large cone-shaped steel structure embedded in the top section of the main tower. The length*width is 50*50cm; the height of the embedded section of the tower column is 0.8m, and the height of the exposed section is 6m; the total weight is about 22.459t.

[0040]Regarding the construction process of the main tower crown, the traditional method is: firstly manufacture, weld and paint the tower crown in the factory as a whole, and then transport the whole tower to the site for lifting and installation. The following problems were found in the practical application of this method: (1) The original design of the overall production of the tower crown structure, due to the heavy weight of the structure and the large geometric size, it is difficult to flanging welding, moving and hoisting during the overall production, and the manufacturing is inconvenient; Moreover, the structural size of the top of the tower c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com