COFs-modified ammonium polyphosphate flame retardant as well as preparation method and application thereof and flame-retardant epoxy resin

An ammonium polyphosphate and epoxy resin technology, applied in the field of flame retardants, can solve the problems of complex APP modification synthesis process, poor compatibility of epoxy resin, strong water absorption of APP, etc., and achieves broad industrial application prospects, high hydrophobicity Sexual, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

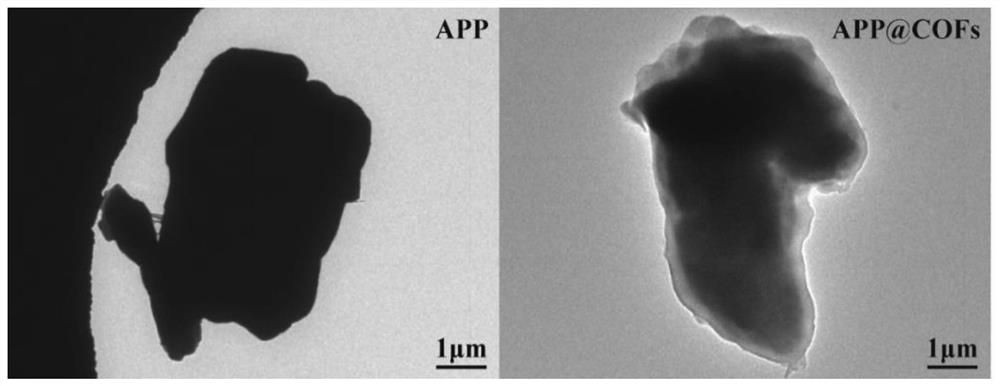

Embodiment 1

[0046] Disperse 1g APP in 200mL methanol to make the concentration 5g / L, stir for 5min; Dissolve formaldehyde in 50mL of methanol to make the concentrations 4.0g / L and 3.0g / L respectively; slowly add the 1,3,5-tris(4-aminophenyl)benzyl alcohol solution into the APP dispersion, dropwise Add 2,5-divinyl terephthalaldehyde solution to the mixed solution slowly dropwise, then add 5mL of 12M acetic acid as a catalyst, continue stirring at 55°C for 1h; centrifuge, and dry in a vacuum oven at 60°C Dry for 24 hours to prepare COFs modified APP flame retardant.

Embodiment 2

[0048] Disperse 1g APP in 125mL ethanol to make the concentration 8g / L, stir for 15min; Dissolve formaldehyde in 50mL of ethanol to make the concentrations 3.0g / L and 2.0g / L respectively; slowly add the 1,3,5-tris(4-aminophenyl)phenylethanol solution into the APP dispersion, dropwise Add 2,5-divinyl terephthalaldehyde solution to the mixed solution slowly and dropwise after the addition is completed, then add 5mL of 12M acetic acid as a catalyst, continue stirring at 35°C for 48h; centrifuge, and dry in a vacuum oven at 60°C Dry for 24 hours to prepare COFs modified APP flame retardant.

Embodiment 3

[0050] Disperse 1g APP in 200mL acetonitrile to make the concentration 5g / L, stir for 30min; Dissolve formaldehyde in 50mL acetonitrile to make the concentrations 2.0g / L and 1.3g / L respectively; slowly add the 1,3,5-tris(4-aminophenyl)phenylacetonitrile solution into the APP dispersion, drop Add 2,5-divinyl terephthalaldehyde solution slowly to the mixed solution dropwise after the addition is complete, then add 5mL of 12M acetic acid as a catalyst, continue stirring at 25°C for 72h; centrifuge, and dry in a vacuum oven at 60°C Dry for 24 hours to prepare COFs modified APP flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

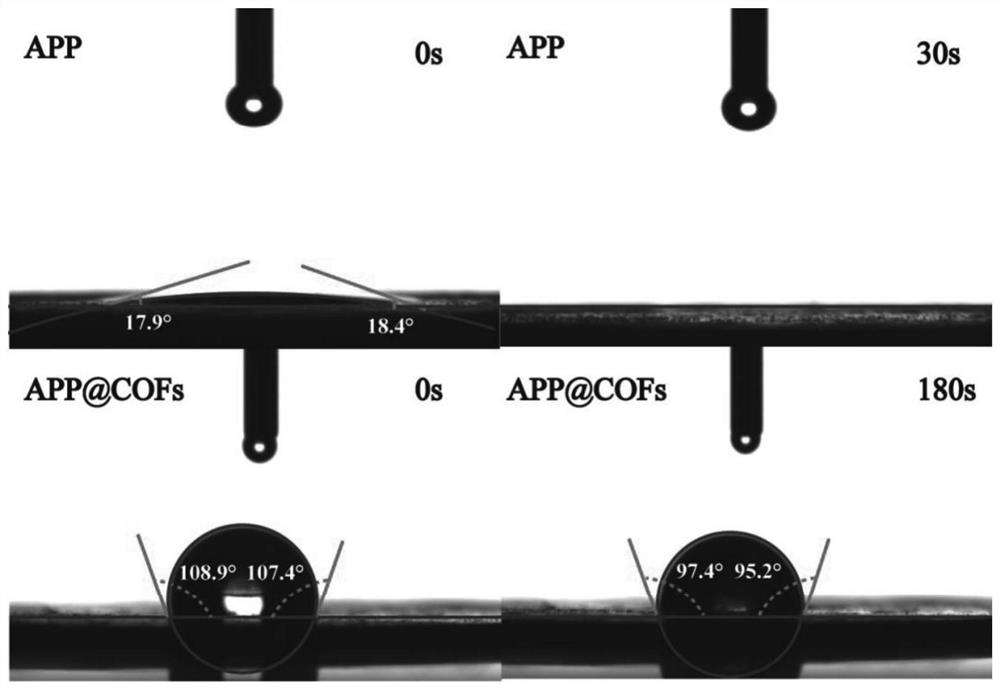

| water contact angle | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com