Colorful non-woven fabric tissue and preparation method thereof

A technology of non-woven fabrics and spunlace non-woven fabrics, which is applied in the field of textile non-woven fabrics, can solve problems such as unsatisfactory product quality for consumers, and achieve excellent natural antibacterial properties, good skin care functions, water absorption and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

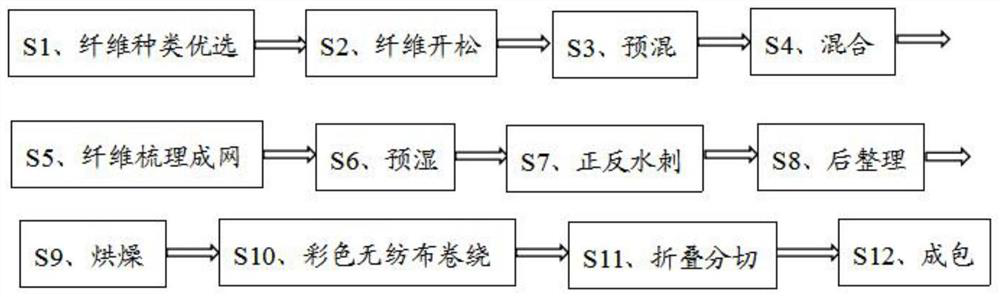

[0051] The present invention also provides a kind of preparation method of colored non-woven paper towel, and technological process is as follows figure 1 As shown, the fiber type is selected → fiber opening → premixing → mixing → fiber carding → pre-wetting → front and back spunlace → finishing → drying → colored non-woven fabric winding → folding and cutting → baling, including The following steps:

[0052] (1) Select the weight ratio of fiber type and raw materials: 75-92% of this white bamboo pulp fiber, 5-20% of colored polylactic acid fiber and 3-5% of natural dyed colored super strong antibacterial fiber.

[0053] (2) Make colored spunlace non-woven fabric: open bamboo pulp fiber, polylactic acid fiber and natural dyed super strong antibacterial fiber with a fiber fineness of 1d-1.5d and a length of 38mm, and then mix them. It is preferable to premix the polylactic acid fiber with a relatively small proportion and the natural dyed super strong antibacterial fiber first...

Embodiment 1

[0056] The present embodiment provides a kind of preparation method of colored non-woven paper towel, comprises the following steps:

[0057] (1) Selection of fiber types is preferred: the fiber types are off-white bamboo pulp lyocell fiber, pink green polylactic acid fiber and naturally dyed apple-colored super antibacterial fiber, the fiber fineness is 1d, and the fiber length is 38mm. The ratio is: natural white bamboo pulp fiber accounts for 92%, pink-green polylactic acid fiber accounts for 5%, and natural dyed apple-colored super antibacterial fiber accounts for 3%.

[0058] (2) Make colored spunlace non-woven fabric: open the white bamboo pulp fiber, pink green polylactic acid fiber and naturally dyed apple-colored super antibacterial fiber first, and then mix them. % polylactic acid fiber and 3% natural dyed super strong antibacterial fiber are pre-mixed in proportion, and then the pre-mixed mixed fiber with a ratio of 8% and bamboo pulp fiber with a ratio of 92% are m...

Embodiment 2

[0062] The present embodiment provides a kind of preparation method of colored non-woven paper towel, comprises the following steps:

[0063] (1) Select the fiber type: the fiber type is white bamboo pulp lyocell fiber, pink polylactic acid fiber and natural dyed apple color super antibacterial fiber, the fiber fineness is 1.3d, the fiber length is 38mm, the raw material configuration The ratio is: white bamboo pulp fiber accounts for 87%, pink polylactic acid fiber accounts for 10%, and naturally dyed apple-colored super antibacterial fiber accounts for 3%.

[0064] (2) Make colored spunlace non-woven fabric: open the white bamboo pulp fiber, pink polylactic acid fiber and naturally dyed apple-colored super antibacterial fiber first, and then mix them. % polylactic acid fiber and 3% natural dyed super strong antibacterial fiber are pre-mixed in proportion, and then the pre-mixed mixed fiber with a ratio of 13% and bamboo pulp fiber with a ratio of 87% are mixed. The equipmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com