Device for cleaning exterior of breather valve through planet flexible shaft hair brush driven by electric hand drill

A technology of electric hand drill and breathing valve, which is applied in the field of cleaning machines, and can solve the problems that the technical documents for cleaning the breathing valve have not yet been found.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

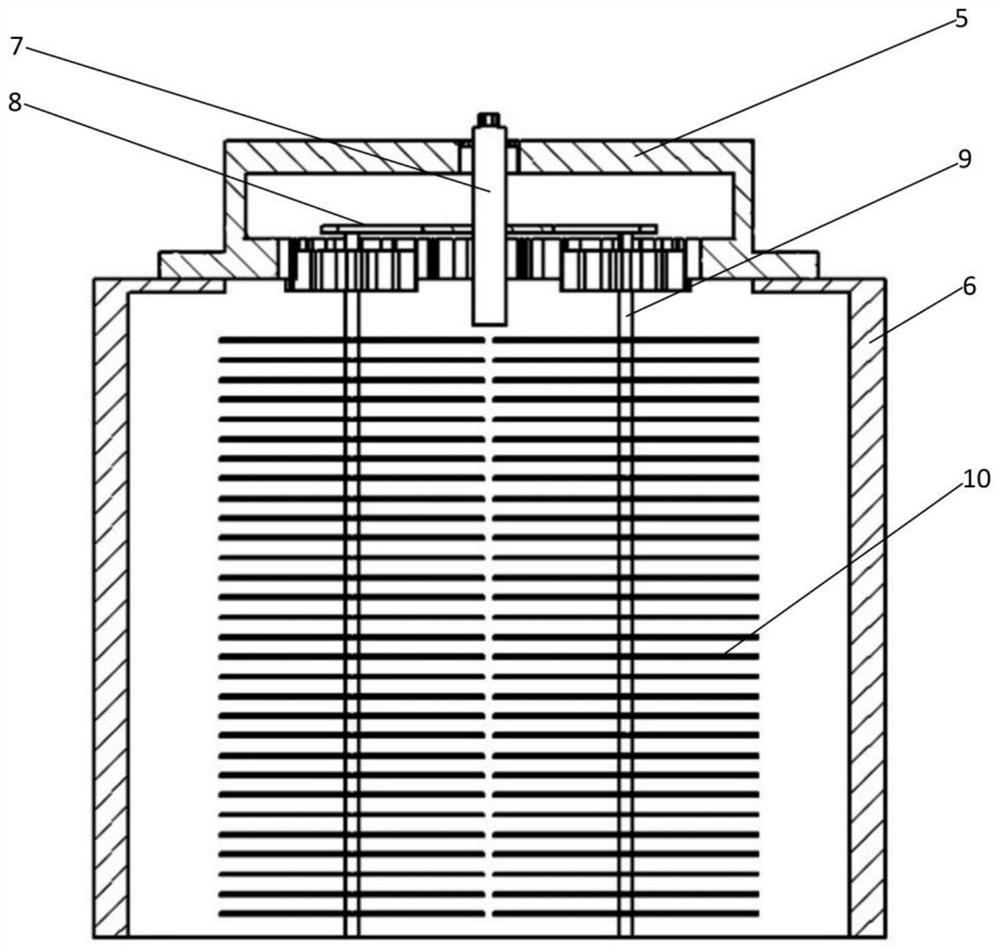

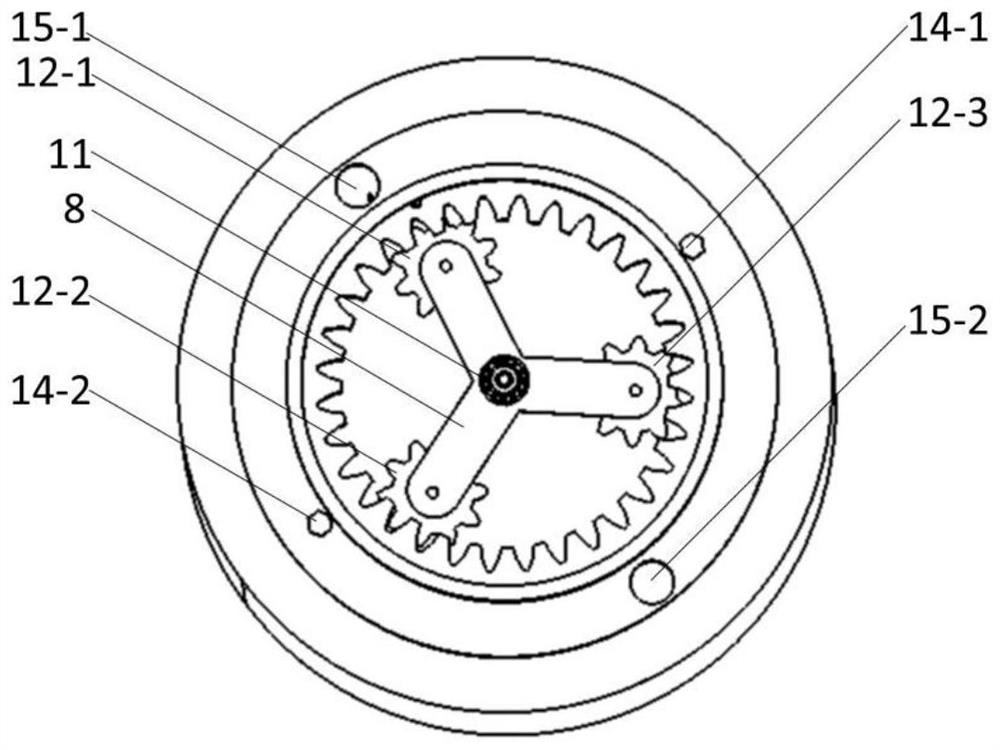

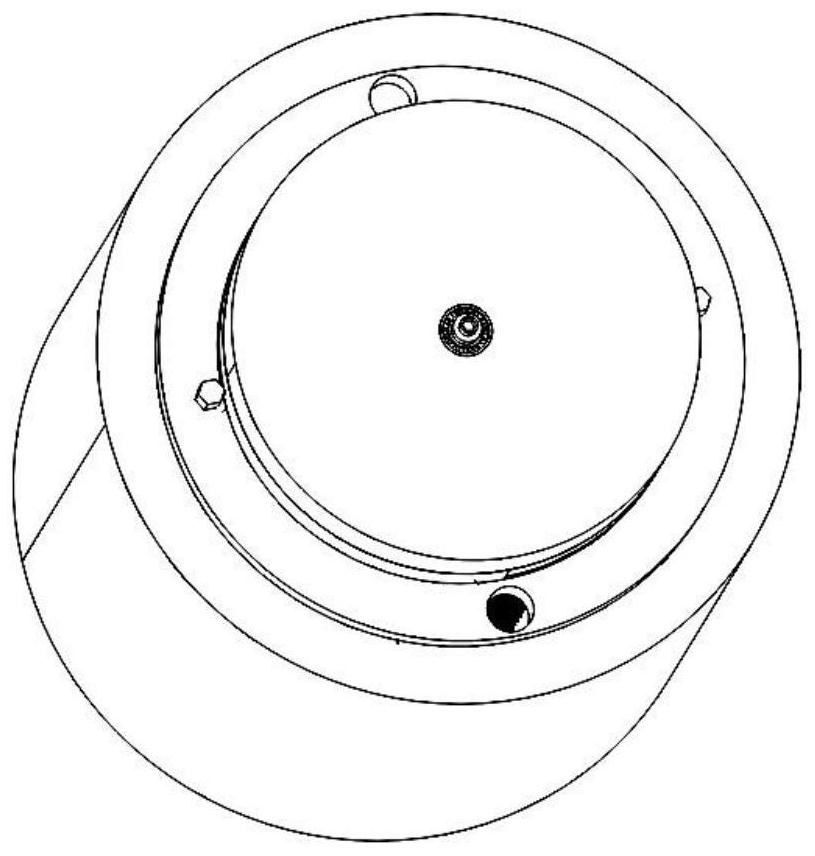

[0026] Such as figure 1 and figure 2 As shown, the present invention is a device for cleaning the outside of the breathing valve with a planetary flexible shaft brush driven by a hand electric drill, including a hand electric drill 1, a chuck 16, a shaft coupling 2, a transmission flexible shaft 3, a split taper pin 4, and a cover 5. Cylinder body 6, bolt group 14, through hole 15, bearing 11, central shaft 7, support plate 8, planetary wheel set 12, rubber shaft 9, brush 10, elastic inner ring 13. It is characterized in that the cover body 5 and the cylinder body 6 are fixed by the bolt group 14 , the inner ring of the bearing 11 is interference fit with the central shaft 7 , the outer ring is interference fit with the cover body 5 , and the central shaft 7 is fixed with the support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com