Ultrasonic cleaning method and device

An ultrasonic cleaning and ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as complex processes, high cleaning costs, and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

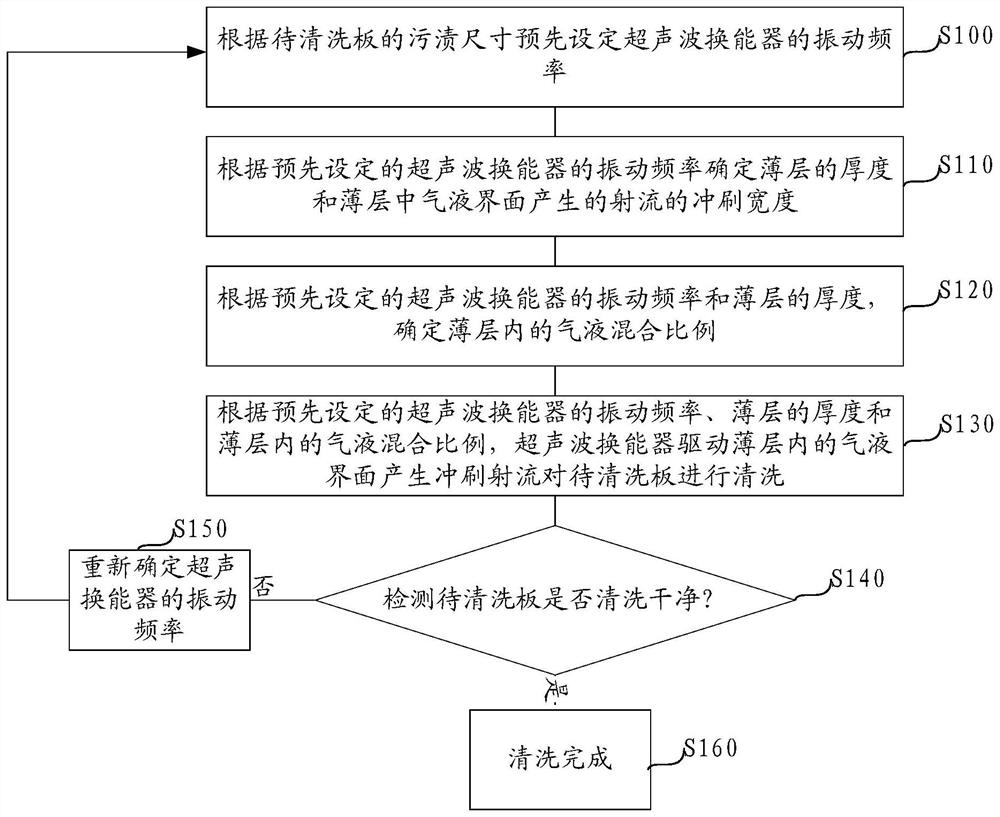

[0026] Below through the accompanying drawings and examples, the technical scheme of the present invention is described in further detail.

[0037] This step is used to detect whether the plate 200 to be cleaned is cleaned. The plate 200 to be cleaned can be detected by a microscope

[0040] Until step S140, it is detected that the plate 200 to be cleaned has been cleaned, and the execution of step S100-step S150 is terminated.

[0045]

[0046]

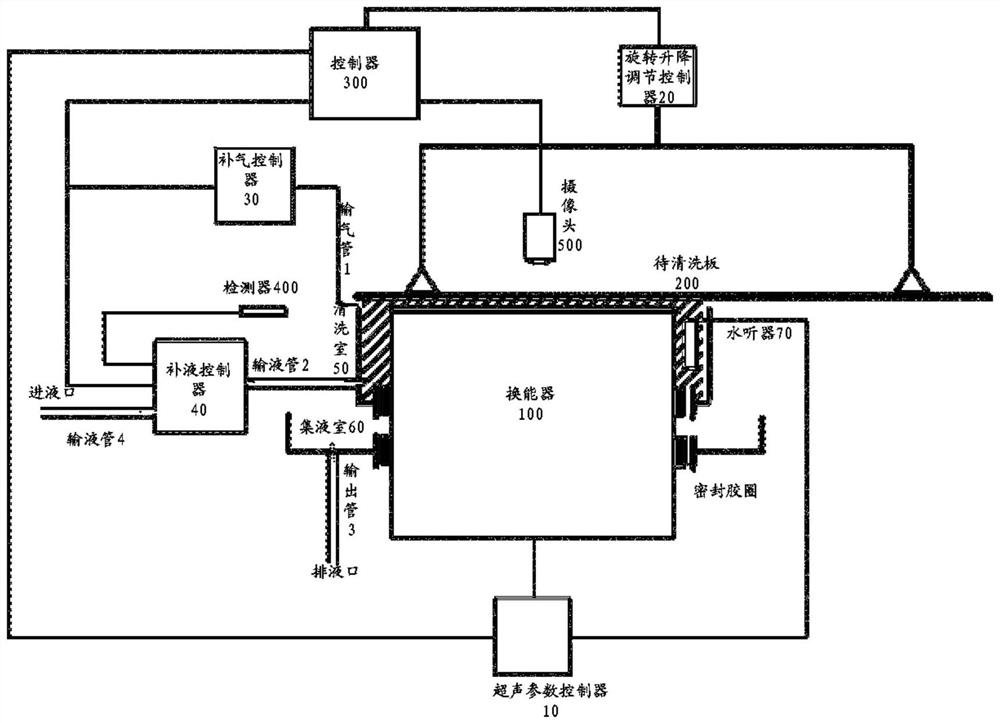

[0058] The controller 300 also includes: a liquid supplement controller 40 and a gas supplement controller 30; a liquid supplement controller 40 and a gas supplement controller 30

[0065] In the embodiment of the present invention, the frequency of the ultrasonic parameter controller is selected at 15kHz-5MHz.

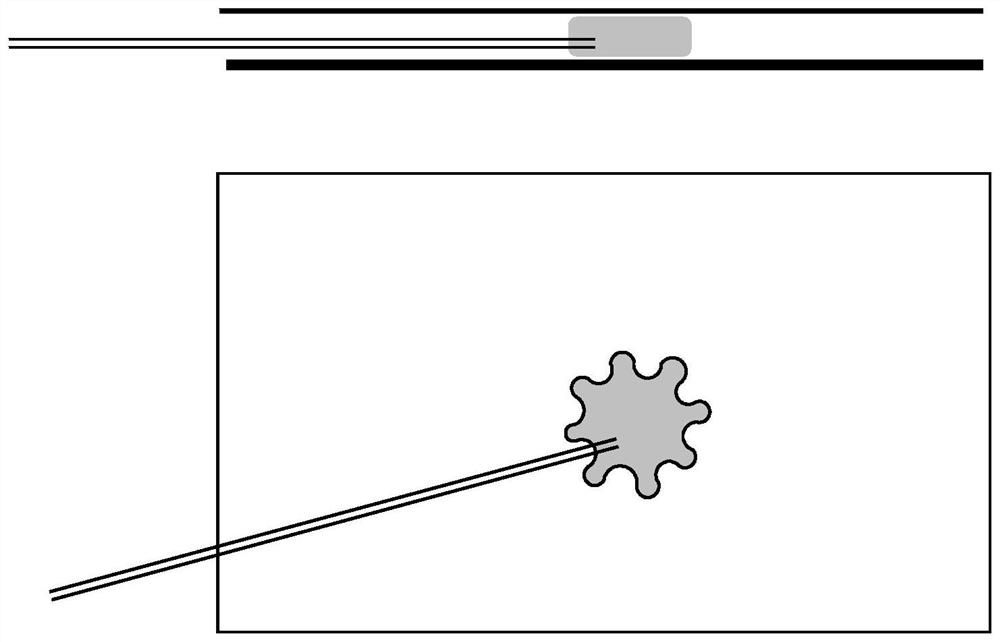

[0068] Figure 3 is a spot cleaning. As shown in Figure 3(a), spot cleaning is the first cleaning method.

[0071] In this embodiment, the point cleaning is to clean the part of the plate 200 to be cleaned.

[0072] FIG. 4 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com