Cylindrical component cleaning method and equipment

A technology for cleaning equipment and cylinders, applied in the field of cylindrical parts cleaning, to achieve good cleaning effect, high degree of automation, and easy automation of assembly line operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods (embodiments), but it is not used as a basis for limiting the present invention.

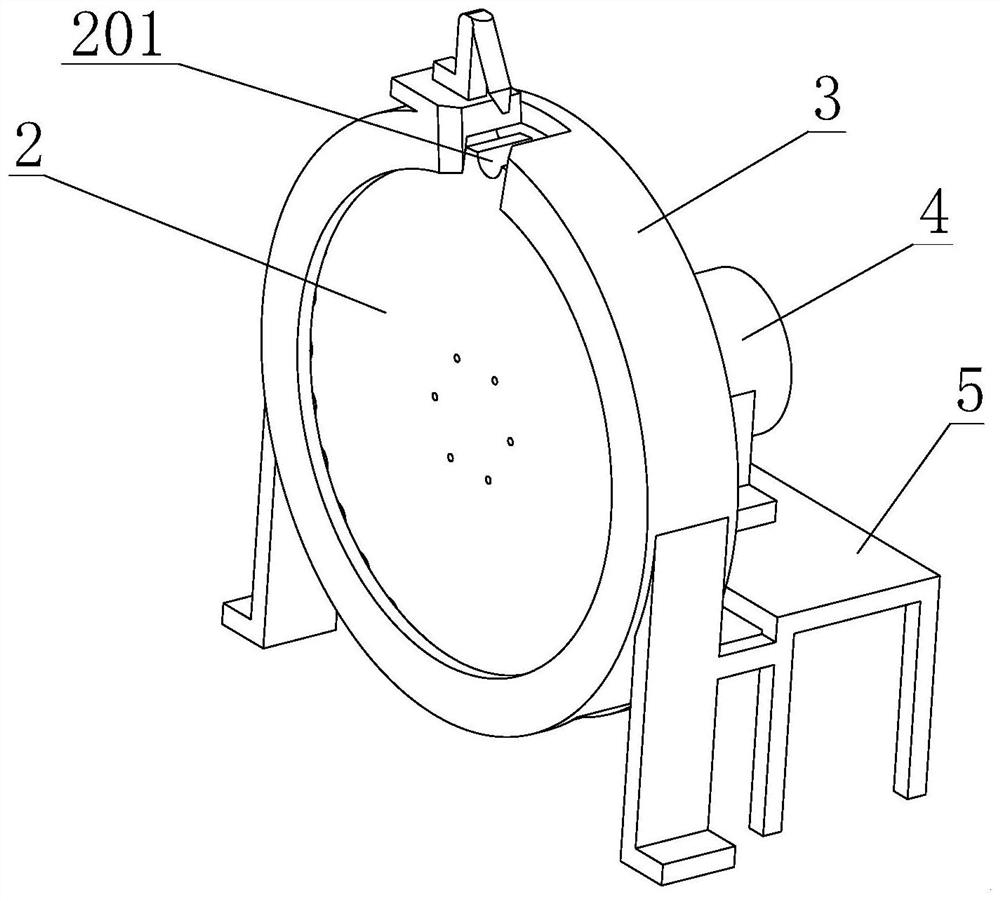

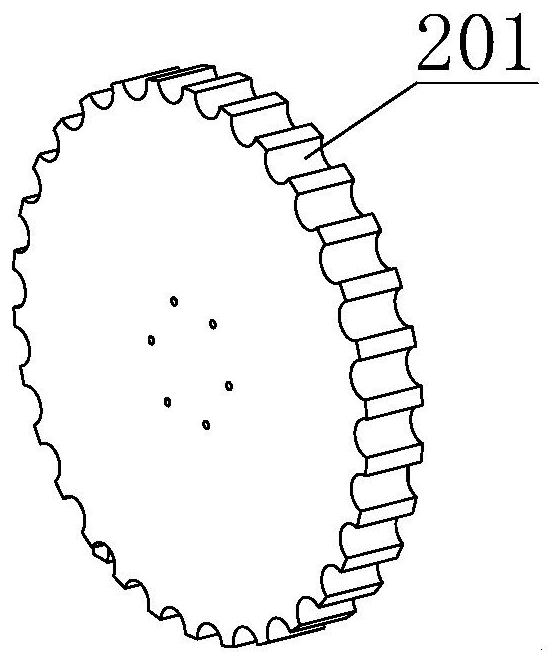

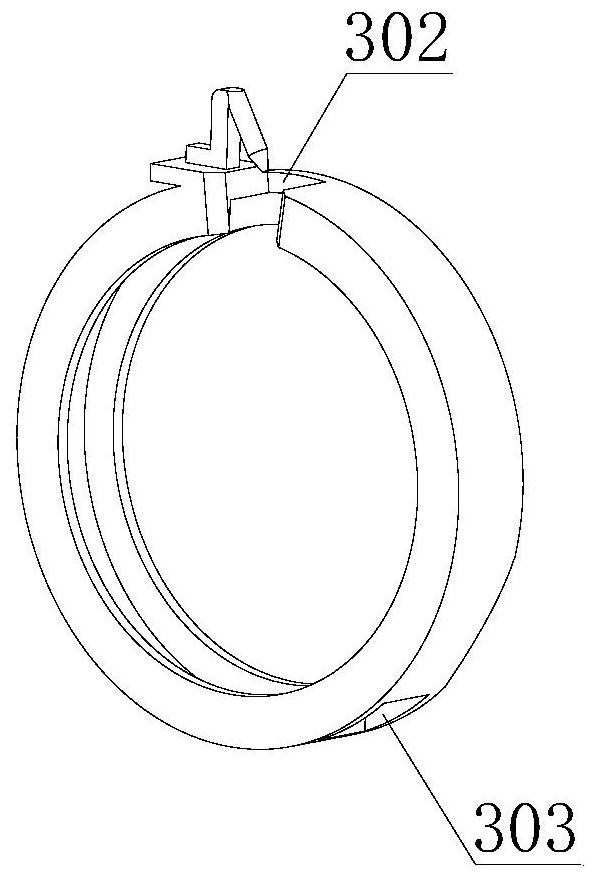

[0027] Cylindrical parts cleaning method of the present invention is realized on the cylinder cleaning device; see Figure 1-6 , the cylindrical cleaning device includes a turntable 2 and a cleaner 3; the turntable 2 is connected to the cleaning power source 4 and can be driven by the cleaning power source 4 for fixed-axis rotation; the cleaner 3 and the cleaning power source 4 are fixed on the installation base The edge of the turntable 2 is provided with a group of feeding tanks 201 for placing cylindrical parts 18, and correspondingly, the cleaner 3 is provided with an arc-shaped cleaning tank 301 that surrounds the edge of the turntable 2; A matching felt 6 is provided in the arc-shaped cleaning tank 301;

[0028] When cleaning: the turntable 2 is dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com