Ultrasonic cleaning method and device

An ultrasonic and ultrasonic technology, used in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of expensive equipment, complicated processes, and high cleaning costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

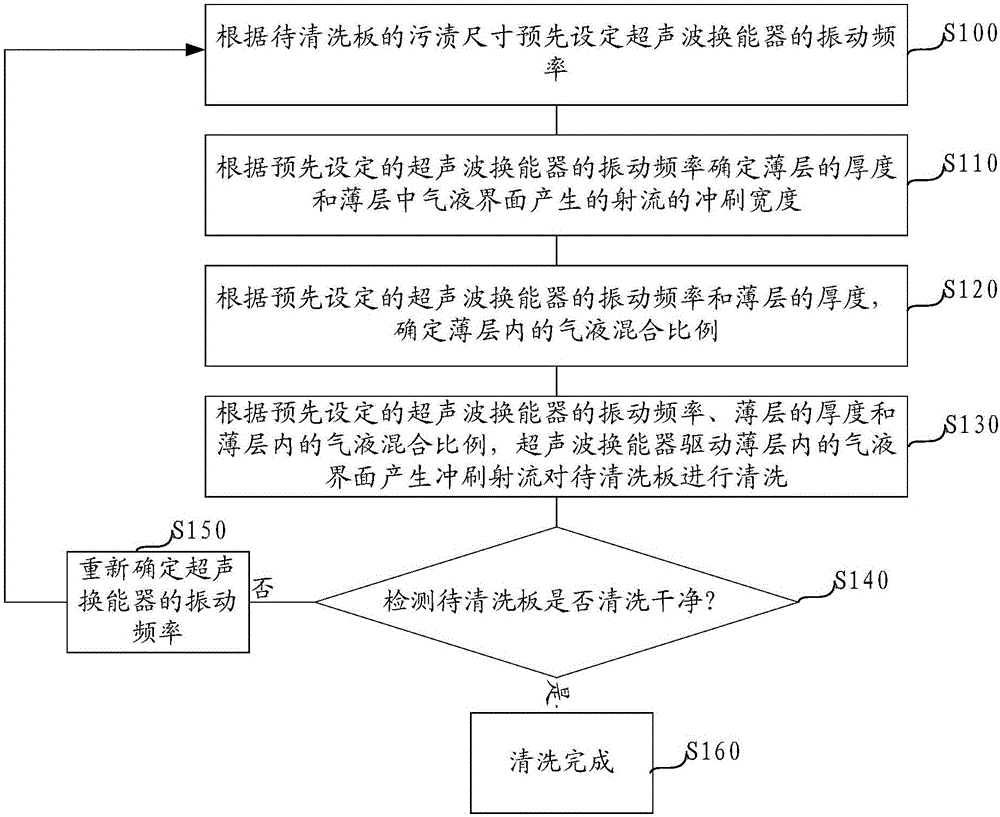

[0027] figure 1 A flowchart of an ultrasonic cleaning method is provided for an embodiment of the present invention. like figure 1 As shown, the specific steps of the ultrasonic cleaning method include:

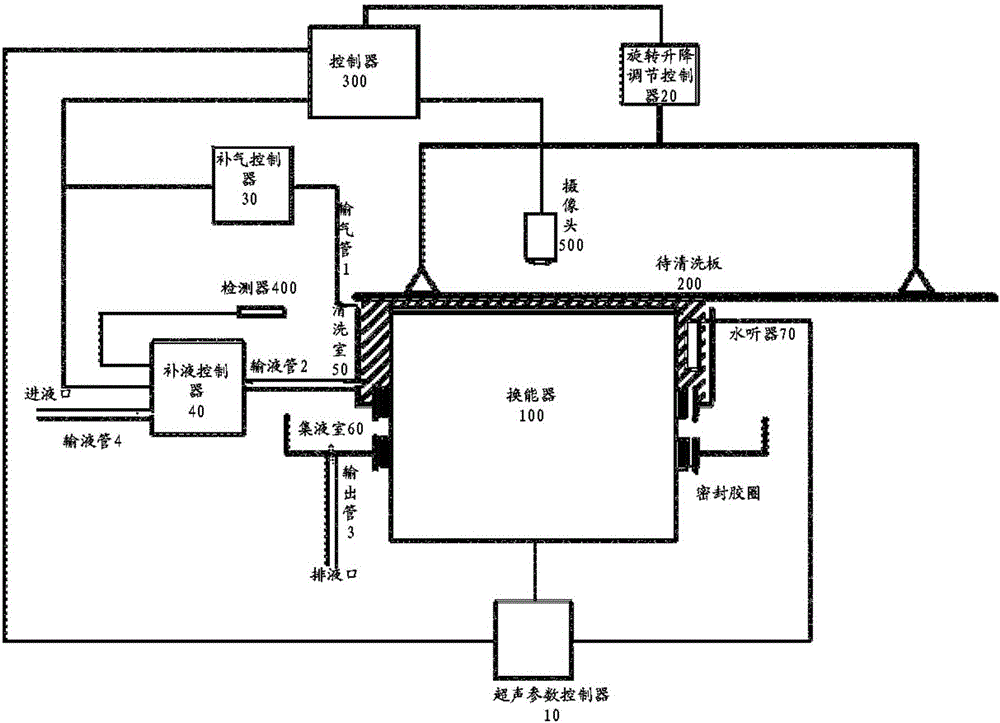

[0028] Applied to an ultrasonic cleaning device mainly composed of an ultrasonic transducer 100 and a plate to be cleaned 200, a thin layer is arranged between the ultrasonic transducer 100 and the plate to be cleaned 200, and it is characterized in that it includes the following steps:

[0029] Vibration is generated by the ultrasonic transducer 100 and radiates to the gas-liquid mixture in the thin layer, so that the thin layer forms a tangential scour on the surface of the plate to be cleaned.

[0030] Specifically: Vibration is generated by the ultrasonic transducer 100 and radiated to the gas-liquid mixture in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com