Miniature environment-resistant circular electric connector

An electrical connector and environment-resistant technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problem that small electrical connectors cannot meet the rated current and external dimensions at the same time, and achieve high rated current, Good sealing performance and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

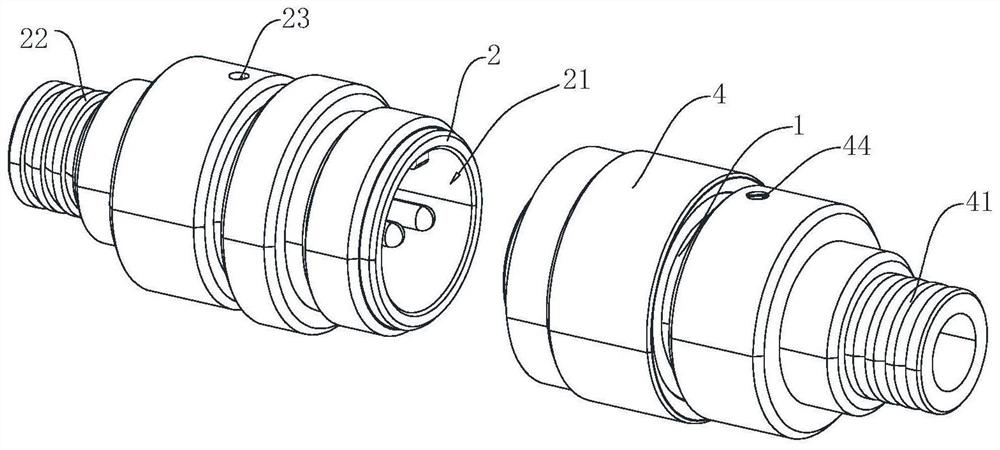

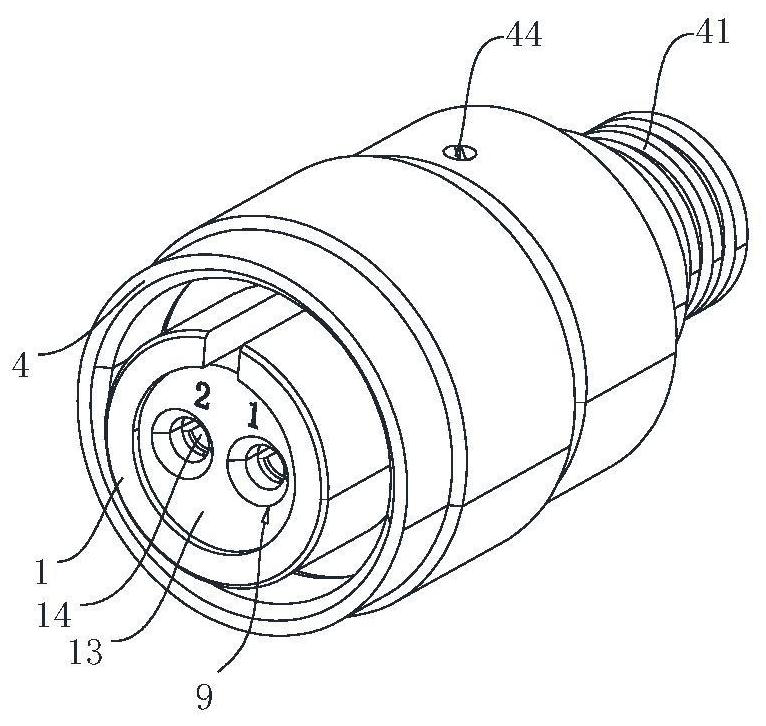

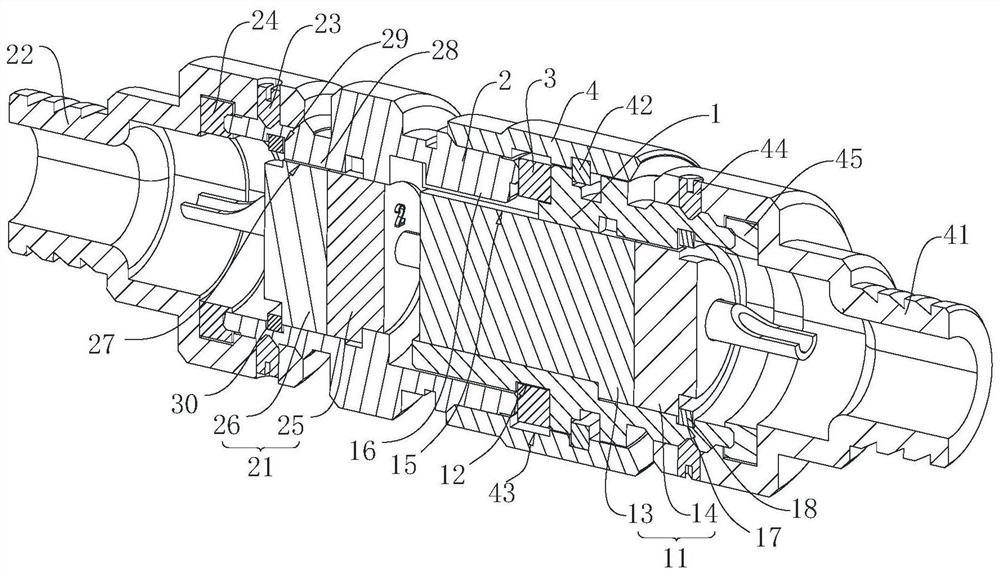

[0034] combine figure 1 and figure 2 , a small environment-resistant circular electrical connector, including a socket and a plug used in conjunction with the socket, the plug includes a first shell 1 and a plug body 11 disposed inside the first shell 1, and the socket includes a second shell 2 And the socket body 21 arranged inside the second housing 2; wherein, it also includes a sealing structure for sealing the gap between the first housing 1 and the second housing 2, and the outer wall of the first housing 1 is provided with a first ring The locking groove 12 , the sealing structure includes a first annular sealing gasket 3 disposed in the first annular locking groove 12 , and the front end of the second housing 2 is in contact with the outside of the first annular sealing gasket 3 .

[0035] Specifically, both the first housing 1 and the second housing 2 are hollow, the plug body 11 is installed in the first housing 1, and the socket body 21 is installed in the second ...

Embodiment 2

[0045] combine Figure 4 , in this embodiment, the outer side of the first annular gasket 3 is provided with a first relief groove 5 for the front end of the second housing 2 to be embedded in, and the sealing structure also includes a fourth groove fixed at the front end of the second housing 2 . Annular gasket 51, a wedge-shaped block 52 fixed on the front end of the first housing 1, the wedge-shaped block 52 is arranged in a ring shape, and one end extends into the first relief groove 5, and the fourth annular gasket 51 is provided with a wedge-shaped block 52 The second relief groove 53 is embedded, and the fourth annular gasket 51 is pressed against the first relief groove 5 after the wedge-shaped block 52 is inserted into the second relief groove 53 .

[0046] During installation, the fourth annular gasket 51 is pre-installed on the front end of the second housing 2. It should be noted that the front end of the second housing 2, that is, the end of the second housing 2 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com