Power distribution automation terminal intelligent warehouse dispatching system

A technology of power distribution automation and intelligent warehouse adjustment, applied in the field of automation, can solve the problems of long test time, many human interventions, and low test efficiency, so as to improve authenticity and reliability, ensure traceability, and reduce human intervention factors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

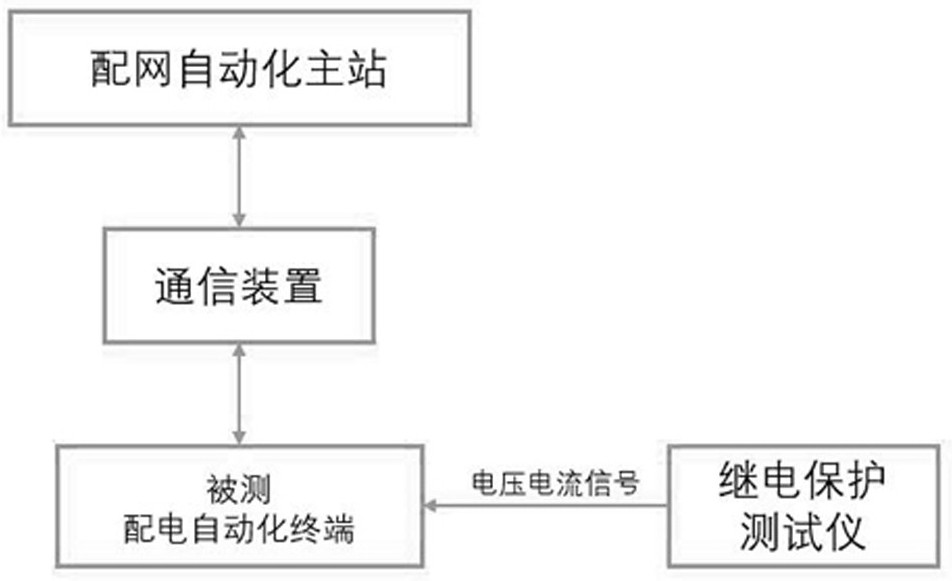

Problems solved by technology

Method used

Image

Examples

Embodiment 1

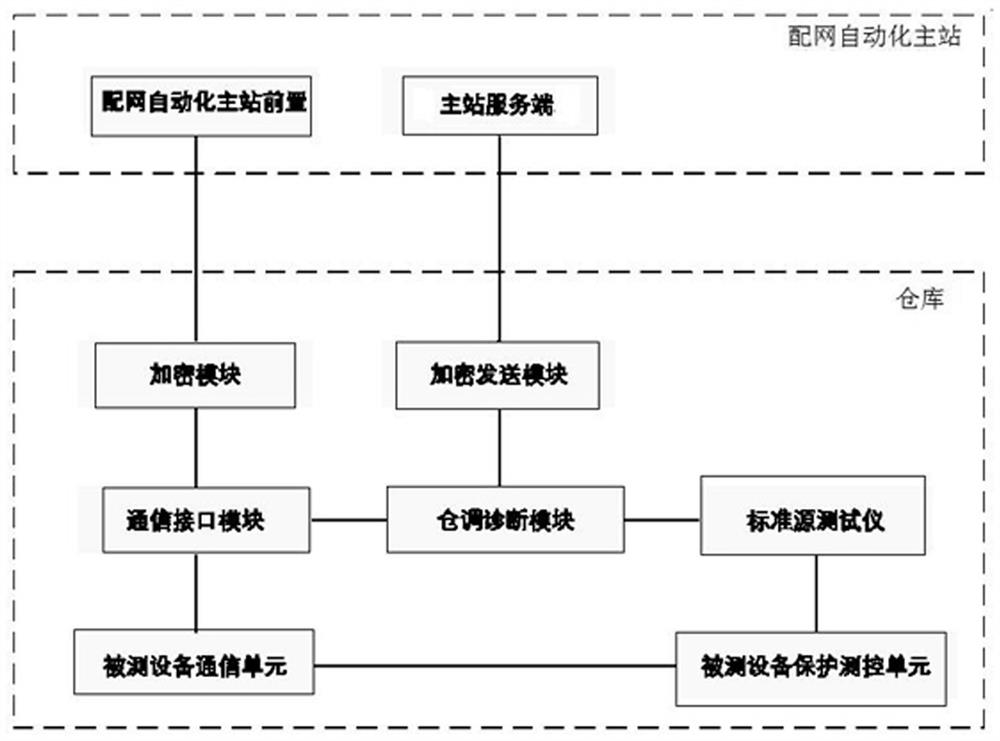

[0027] Example 1: See figure 2 , an intelligent warehouse dispatching system for a distribution automation terminal, including a distribution network automation master station part and a warehouse part, the distribution network automation master station part including a distribution network automation master station front and a master station server, and the master station server deployment In the main station computer room, it is used to receive the diagnosis results sent by the warehouse, to make statistics and analysis on the diagnosis results, and to discover terminal familial defects in time. Interface, attaching the results of each warehouse adjustment to the debugging process as the key basis for judging whether the debugging is qualified;

[0028] The warehouse part includes an encryption module, a communication interface module, an encrypted sending module, a warehouse adjustment diagnosis module, a communication unit of the device under test, a standard source teste...

Embodiment 2

[0036] Embodiment 2, the specific examples are compared as follows:

[0037] (1) Traditional open-loop warehouse adjustment inspection process:

[0038] 1) The operator in the warehouse calls the staff of the main station and informs that the telemetry can be started;

[0039] 2) The staff at the master station operate the software of the master station system, open the protocol message communication page corresponding to the terminal device under test, find the point data corresponding to the telemetry, and inform the warehouse staff after making a phone call;

[0040] 3) The warehouse personnel operate the relay protection tester, manually input the voltage configuration parameters, click to start increasing the output voltage of 220V, and call the main station personnel to inform the increase;

[0041] 4) The staff at the main station checks the voltage corresponding telemetry point data with a primary voltage value of 10.8530kV and a secondary voltage of 238.766V, and man...

Embodiment 3

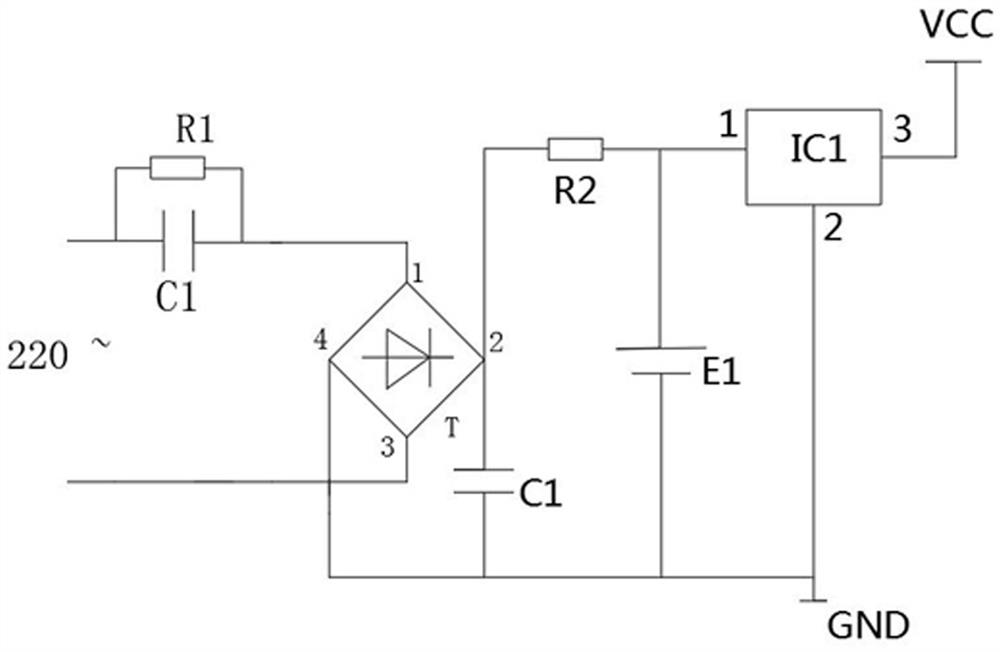

[0058] Embodiment 3, on the basis of Embodiment 1, also includes a power supply part, and the power supply part is composed of a mains power supply and a battery, such as image 3 As shown, it includes resistor R1, capacitor C1, rectifier T, capacitor C1, battery E1 and voltage regulator IC1. One end of resistor R1 is connected to capacitor C1 and 220V AC, and the other end of resistor R1 is connected to the other end of capacitor C1 and rectifier T. Port 1, port 2 of rectifier T is connected to resistor R2 and capacitor C1, the other end of resistor R2 is connected to the positive pole of battery E1, IC1 and port 1 of voltage regulator IC1, port 2 of voltage regulator IC1 is connected to the negative pole of battery E1, capacitor The other end of C1 and the port 4 of the rectifier T, the port 3 of the voltage regulator IC1 output stable direct current VCC, the model of the voltage regulator IC1 is LM7812, after the 220V mains is stepped down and rectified, part of it charges t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com