High-value utilization of wood-based biomass and application of wood-based biomass in preparation of biological asphalt

A technology of bio-asphalt and biomass, which is applied in the direction of bio-fuel, building structure, special form of dry distillation, etc., can solve the problems of low utilization efficiency of wood-based biomass, restrictions on the promotion and application of bio-asphalt, and the complexity of bio-asphalt preparation technology. Achieve high utilization rate of solid waste resources, significant economic and social benefits, reduce environmental pollution and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

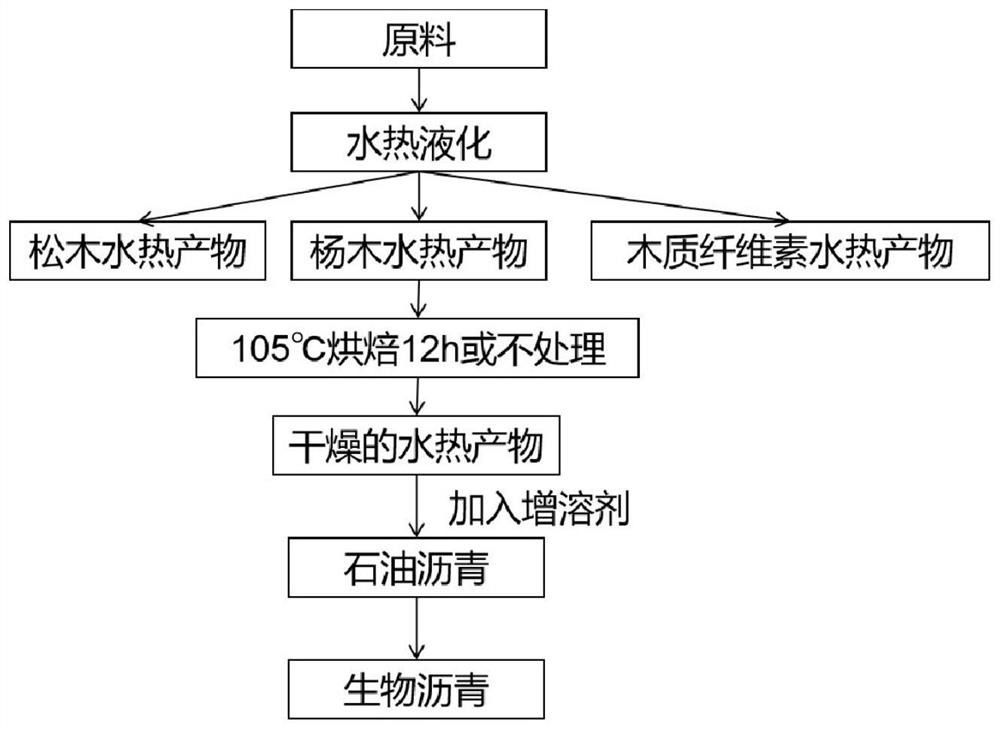

[0015] The high-value utilization of wood-based biomass in this example refers to the hydrothermal liquefaction of wood-based biomass with an average particle size of 2 mm in a high-temperature and high-pressure reactor, using deionized water as a solution, and choosing a residence time of 30 minutes and a temperature of 280 °C. , with a pressure of 6.5MPa to obtain a water-containing hydrothermal liquefaction product (a mixture of bio-oil and biochar), and then the hydrothermal liquefaction product was simply baked (dried at 105°C for 12 hours) to remove moisture to obtain a dry hydrothermal liquefaction product. 100% hydrothermal liquefaction products can replace petroleum asphalt, forming a high-value utilization method of wood-based biomass.

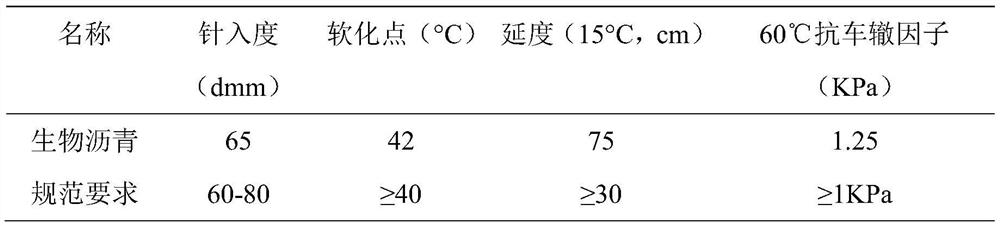

[0016] The proportioning of wood-based biological asphalt in the present embodiment is: 10% hydrothermal liquefaction product, 85% No. 70 petroleum pitch, 5% solubilizer trimethylbenzene.

[0017] The preparation method of wood-based...

Embodiment 2

[0022] The high-value utilization of wood-based biomass in this example refers to the hydrothermal liquefaction of wood-based biomass with an average particle size of 2 mm in a high-temperature and high-pressure reactor, using deionized water as a solution, and choosing a residence time of 30 minutes and a temperature of 280 °C. , with a pressure of 6.5MPa to obtain a water-containing hydrothermal liquefaction product (a mixture of bio-oil and biochar), and then the hydrothermal liquefaction product was simply baked (dried at 105°C for 12 hours) to remove moisture to obtain a dry hydrothermal liquefaction product. 100% hydrothermal liquefaction products can replace petroleum asphalt, forming a high-value utilization method of wood-based biomass.

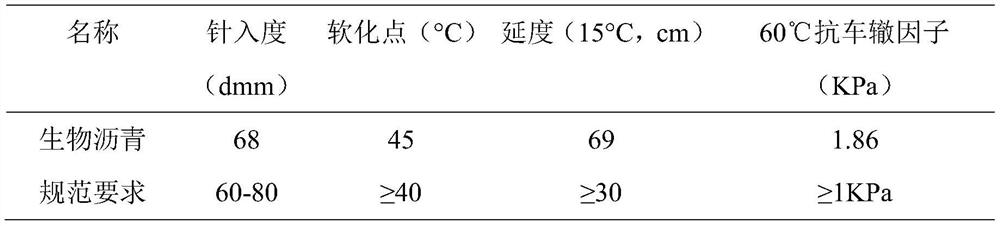

[0023] The proportioning of wood-based biological asphalt in the present embodiment is: 20% hydrothermal liquefaction product, 75% No. 70 petroleum pitch, 5% solubilizer trimethylbenzene.

[0024] The application method of wood-based...

Embodiment 3

[0029] The high-value utilization of wood-based biomass in this example refers to the hydrothermal liquefaction of wood-based biomass with an average particle size of 2 mm in a high-temperature and high-pressure reactor, using deionized water as a solution, and choosing a residence time of 30 minutes and a temperature of 280 °C. , with a pressure of 6.5MPa to obtain a water-containing hydrothermal liquefaction product (a mixture of bio-oil and biochar), and then the hydrothermal liquefaction product was simply baked (dried at 105°C for 12 hours) to remove moisture to obtain a dry hydrothermal liquefaction product. 100% hydrothermal liquefaction products can replace petroleum asphalt, forming a high-value utilization method of wood-based biomass.

[0030] The proportioning of wood-based biological asphalt in the present embodiment is: 30% hydrothermal liquefaction product, 65% No. 70 petroleum pitch, 5% solubilizer hydrogenated castor oil.

[0031] The application method of woo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com