Plate heat exchanger plate transferring system and transferring method thereof

A plate heat exchanger and plate technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of low efficiency, laborious plate transfer, etc., and achieve the effect of easy adjustment and convenient stacking and collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

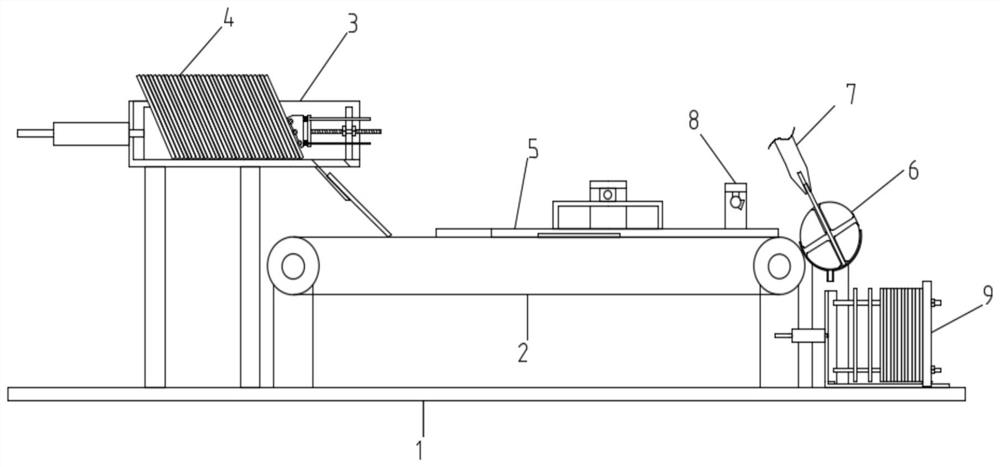

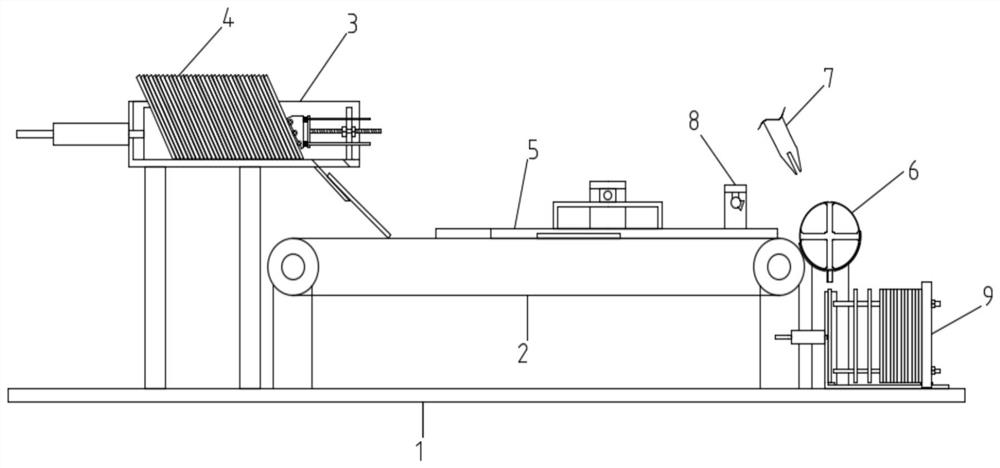

[0040] as attached Figure 1-3 As shown, the present invention provides a kind of technical scheme:

[0041]A plate transfer system for a plate heat exchanger, comprising a bottom plate 1, a conveyor belt 2 is provided in the middle of the top of the bottom plate 1, a storage and unloading mechanism 3 is provided on the input side of the conveyor belt 2, and a plate 4 is loaded in the storage and unloading mechanism 3 , the top of the conveyor belt 2 is provided with a plate guide mechanism 5, the output side of the conveyor belt 2 is provided with a plate turning and unloading mechanism 6, and the upper side of the plate turning and unloading mechanism 6 is provided with a clamping mechanical arm 7. The mechanical arm 7 is used to transfer the plate 4 to the processing equipment, and after the processing is completed, the plate 4 is sent back to the plate turning and unloading mechanism 6. The lower side of the plate turning and unloading mechanism 6 is provided with The fin...

Embodiment 2

[0047] Based on Embodiment 1, this embodiment specifically introduces a structural design of a storage and unloading mechanism:

[0048] as attached Figure 4 As shown, the storage and unloading mechanism 3 includes an outer casing 31, the top and the right end of the outer casing 31 are openings, and an inclined push block 32 is movable in the outer casing 31, and a first electric push rod 33 is installed on the left end of the outer casing 31. The output rod of the first electric push rod 33 runs through the outer shell 31 and is fixedly connected with the left end of the inclined push block 32. The bottom right side of the outer shell 31 is provided with a discharge port 34, and the bottom left end of the discharge port 34 is provided with a discharge port. A partition 37 is arranged on the right side of the top of the plate 35 and the discharge opening 34, and a plate anti-slip mechanism 38 is installed on the left side of the partition 37.

[0049] When the above-mention...

Embodiment 3

[0053] Based on Embodiment 2, this embodiment specifically introduces the structural design of a plate anti-slip mechanism:

[0054] as attached Figure 5 As shown, the plate anti-slip mechanism 38 includes a mounting plate 381, the middle part of the right end of the mounting plate 381 is fixedly connected with an adjusting screw 382, the adjusting screw 382 moves through the partition 37, and the adjusting screw 382 is provided with two sets of adjusting nuts 383, the two sets of adjusting nuts 383 is located on the left and right sides of the partition 37, and the left side of the mounting plate 381 is provided with a slanting block 385, and the right end of the slanting block 385 is fixedly connected with two sets of upper and lower limit rods 384, and the right ends of the limit rods 384 move through the mounting plate in turn. 381 and the partition 37 , a buffer spring 386 is connected between the inclined block 385 and the mounting plate 381 , and the buffer spring 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com