Metal material machining device and method for die-casting formation

A metal material, die-casting molding technology, applied in workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve the problems of copper pipe breakage and difficult to achieve manual recovery, to improve efficiency, solve inconvenient transportation, and improve roughing. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention will be disclosed in the following diagrams. For the sake of clarity, many practical details will be described together in the following description. It should be understood, however, that these practical details should not be used to limit the invention. That is, in some embodiments of the invention, these practical details are not necessary. In addition, for the sake of simplifying the drawings, some well-known and commonly used structures and components will be shown in a simple schematic manner in the drawings.

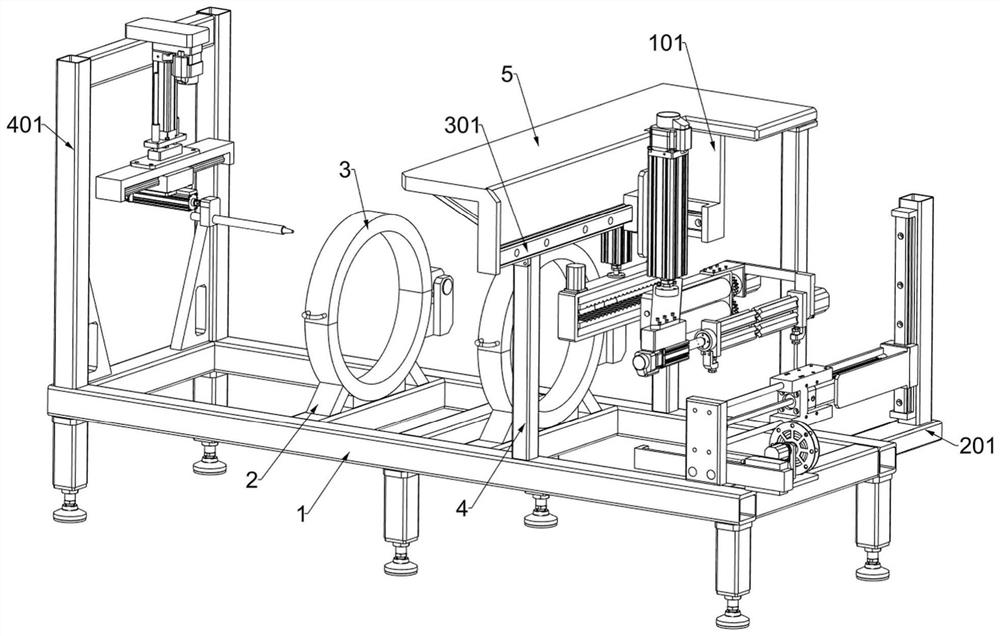

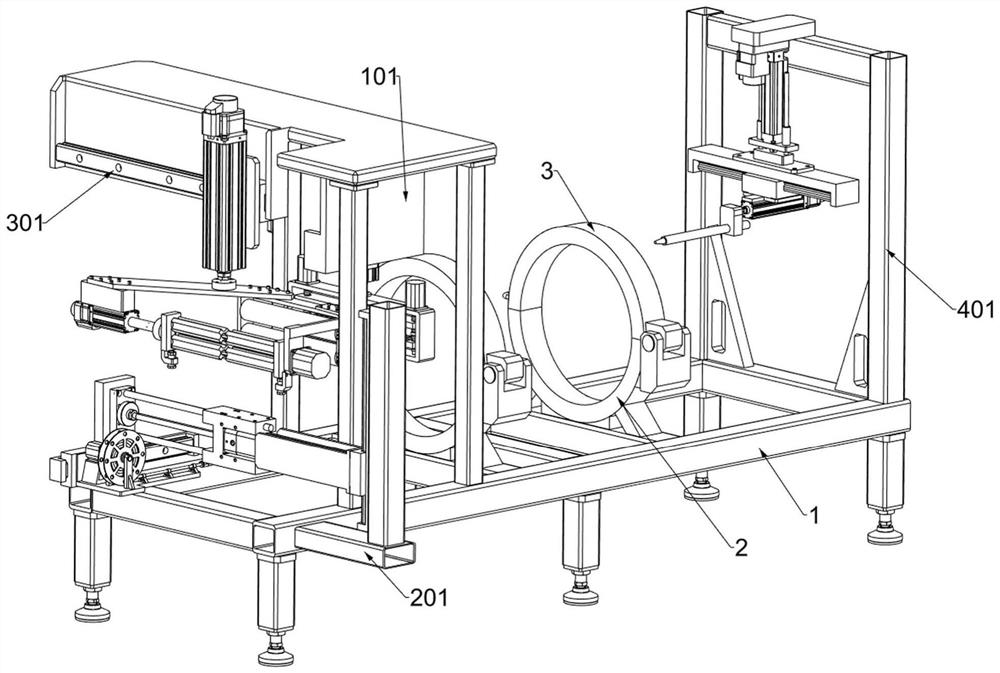

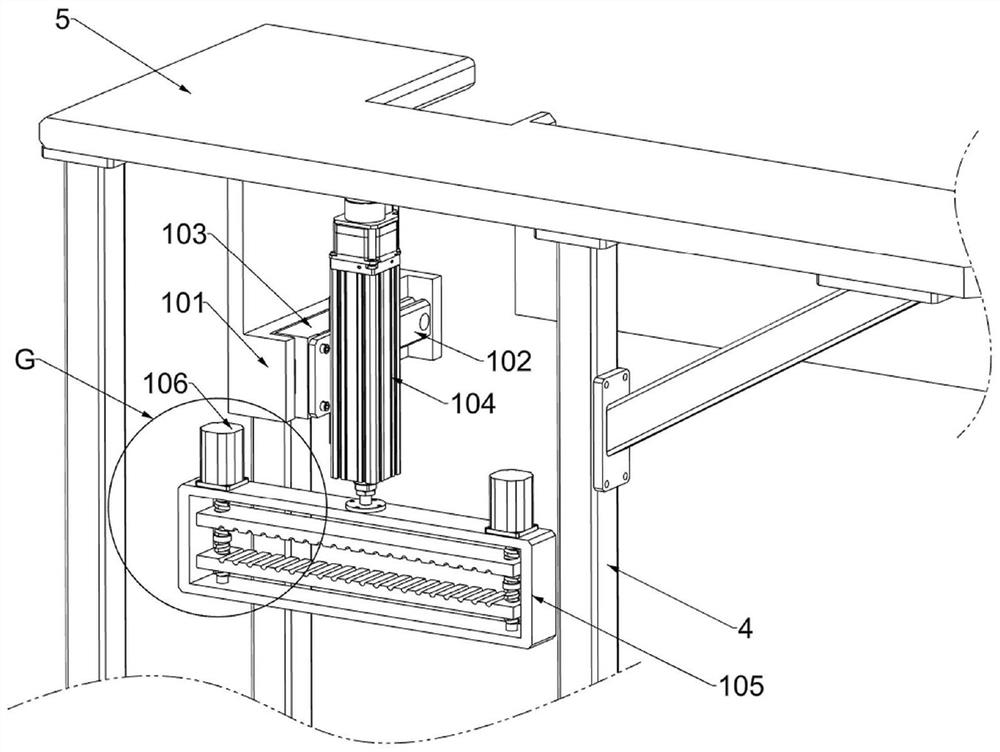

[0034] Such as Figure 1-2 As shown, the present invention is a metal material processing device for die-casting, including a frame 1, a base 2, a lock ring 3, a support column 4, a first fixing plate 5, a pulling system and a material breaking processing system; The middle part of the frame 1 is connected with two bases 2; each of the two bases 2 is connected with a lock ring 3; the upper surface of the frame 1 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com