Wafer semiconductor polishing device and using method thereof

A semiconductor and wafer technology, applied in the field of wafer semiconductor grinding equipment, can solve the problems of time-consuming cleaning, inability to deal with dust in time, and affect processing efficiency, etc., achieve good filterability, avoid cumbersome subsequent cleaning, and improve grinding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

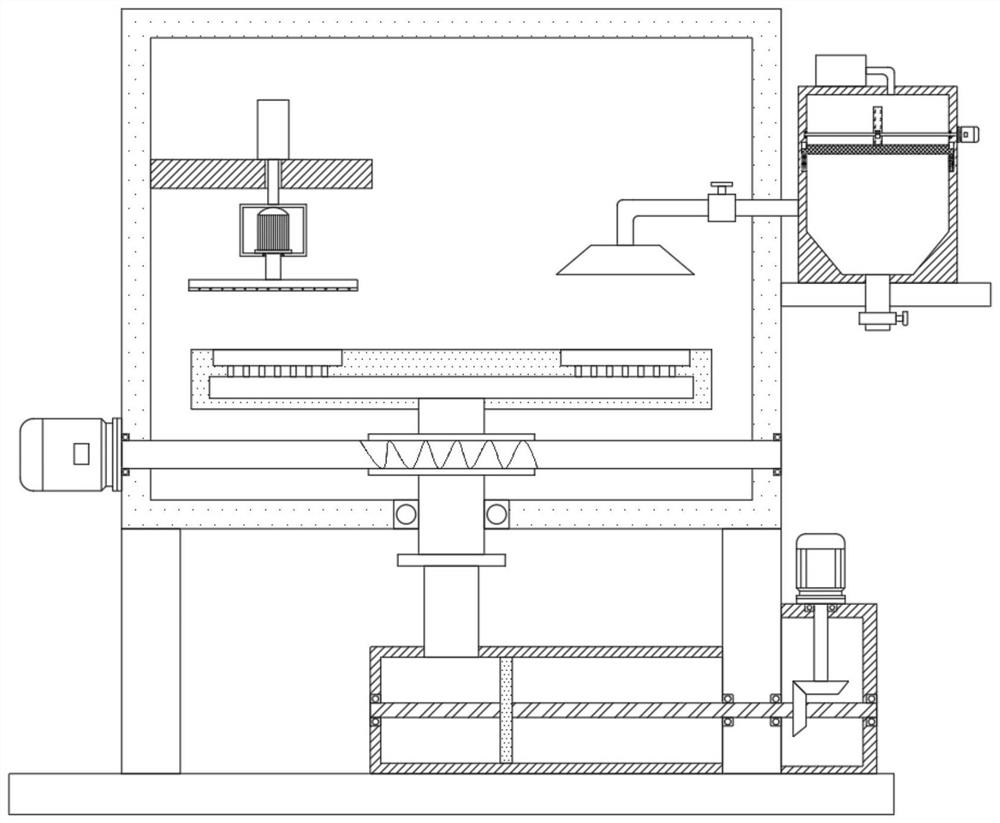

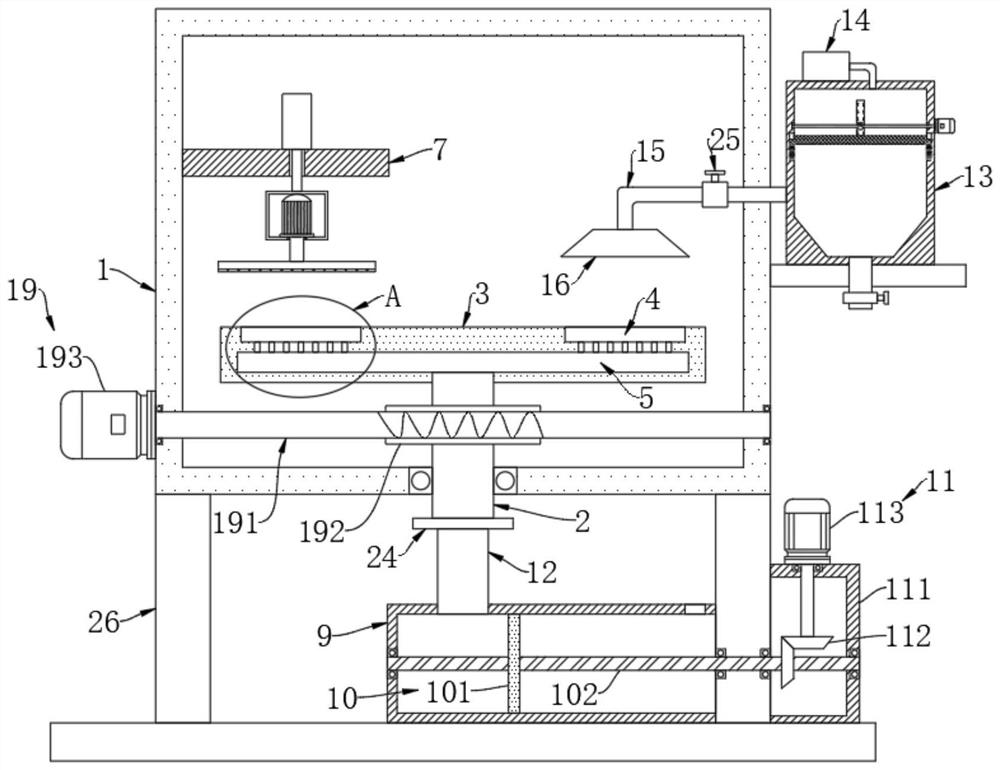

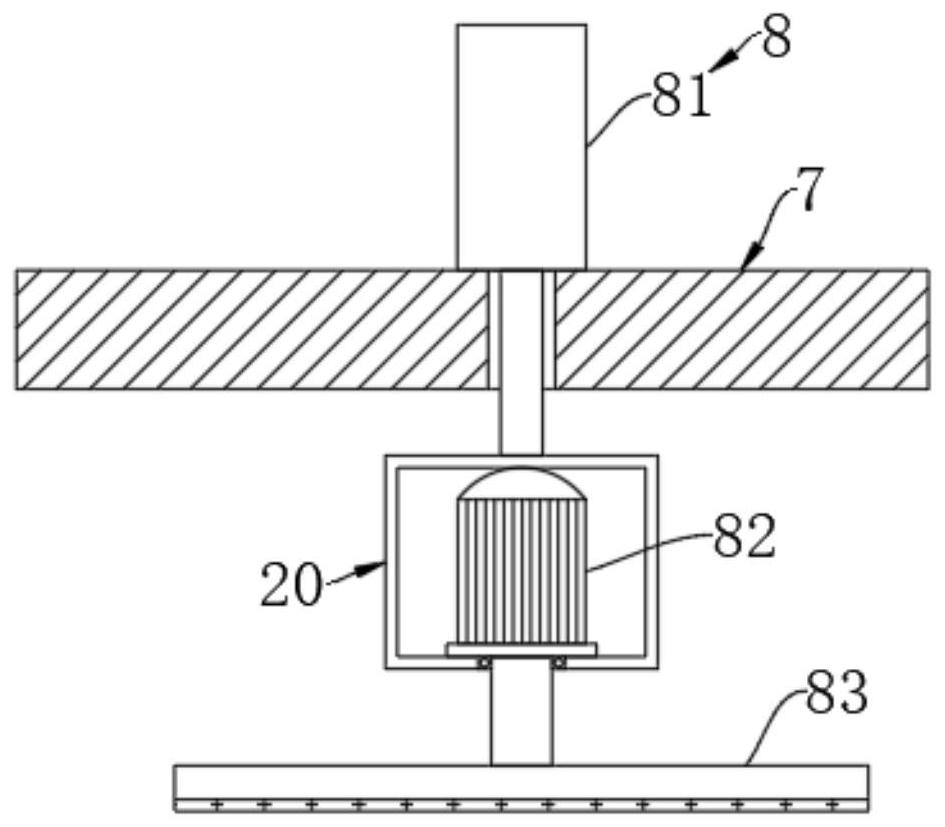

[0029] Such as Figure 1-7 As shown, a wafer semiconductor polishing device includes a polishing box 1 fixedly arranged on a support base 26, a gas pipe 2 is rotatably connected to the polishing box 1, and a fixed seat 3 is fixedly connected to the upper end of the gas pipe 2. On the fixed seat 3 A plurality of placing grooves 4 are provided, and the plurality of placing grooves 4 are distributed in a ring shape, and an air chamber 5 is provided on the fixed seat 3, and the air chamber 5 communicates with the trachea 2, and the placing groove 4 communicates with the air chamber 5 through a plurality of air holes 6 , the grinding box 1 is fixedly connected with a support plate 7, and the support plate 7 is provided with a grinding mechanism 8 matched with the placement groove 4.

[0030] The grinding mechanism 8 includes a cylinder 81, a micro motor 82 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com