Bread fermentation process

A fermentation process and bread technology, applied in the direction of dough fermenter, dough preparation, dough extruder, etc., can solve the problems affecting the quality and taste of bread, achieve excellent temperature conduction performance, reduce labor intensity, and reduce the effect of fermentation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

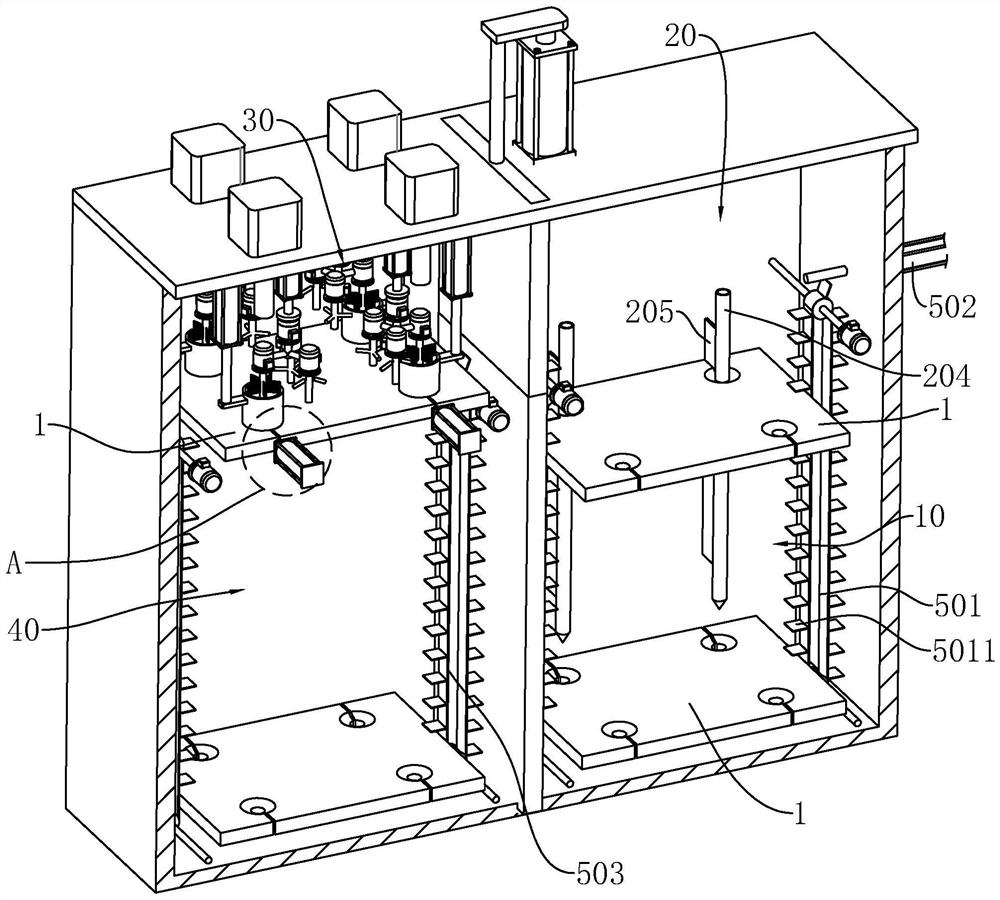

[0043] The following is attached Figure 1-7 The application is described in further detail.

[0044] The embodiment of the present application discloses a middle seed fermentation molding device.

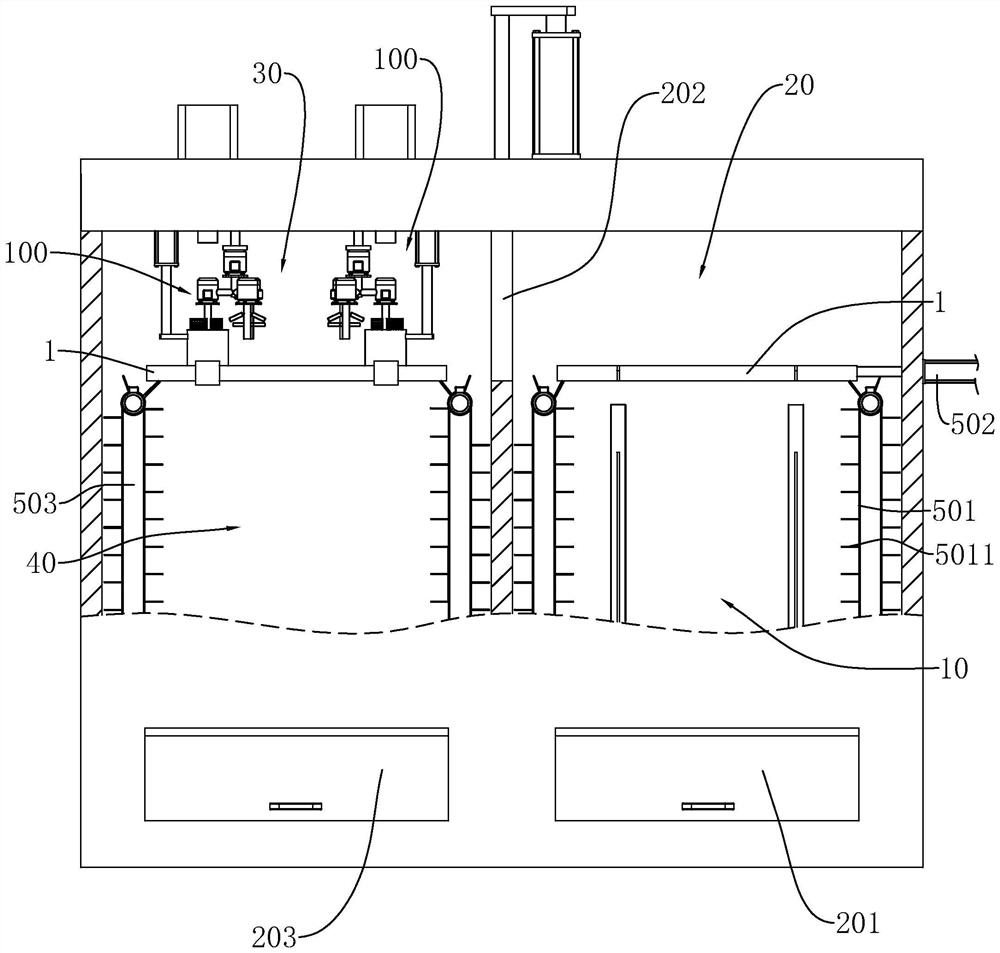

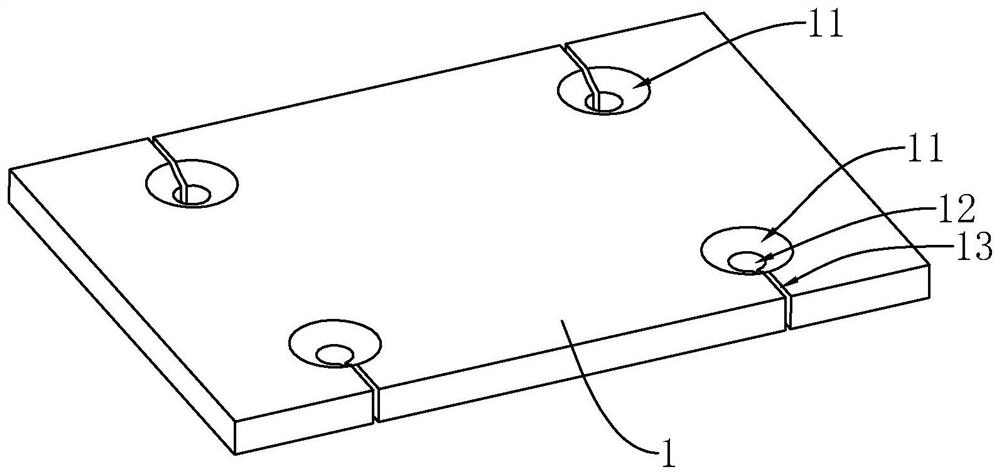

[0045] refer to figure 1 , The medium fermentation molding device includes a low-temperature fermentation chamber 10, a transfer chamber 20, a secondary mixing chamber 30, a final fermentation chamber 40 and a transfer assembly connected in sequence, wherein the secondary mixing chamber 30 is provided with a molding assembly 100.

[0046] like figure 1 As shown, the low-temperature fermentation chamber 10 and the final fermentation chamber 40 are vertically arranged side by side, the transfer chamber 20 is located above the low-temperature fermentation chamber 10, and the secondary mixing chamber 30 is located above the final fermentation chamber 40; the bottom of the low-temperature fermentation chamber 10 is provided with a second A cabinet door 201, the upper end of the low-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com