Forage bundling machine

A baler and fodder technology, which is applied in the field of forage processing, can solve the problems of complex operation, high cost, and heavy physical strength, and achieve the effects of simple operation, improved utilization rate, and high baling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

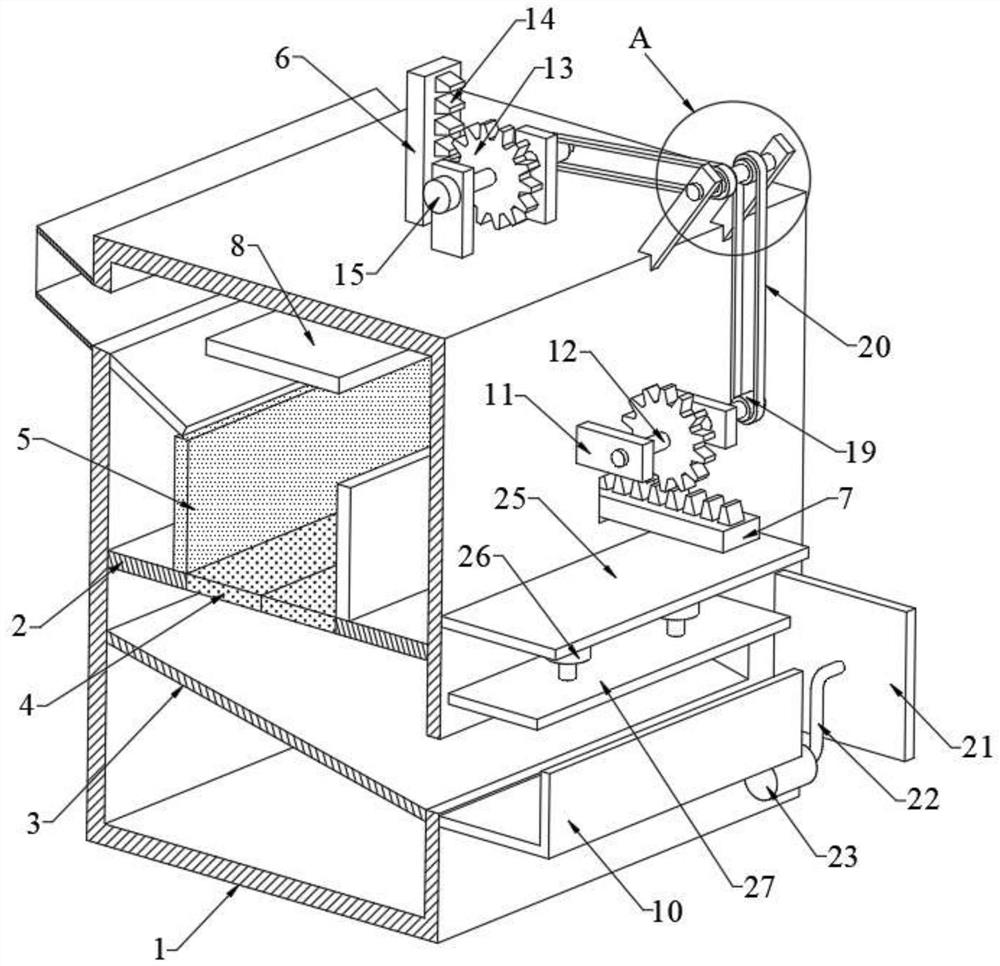

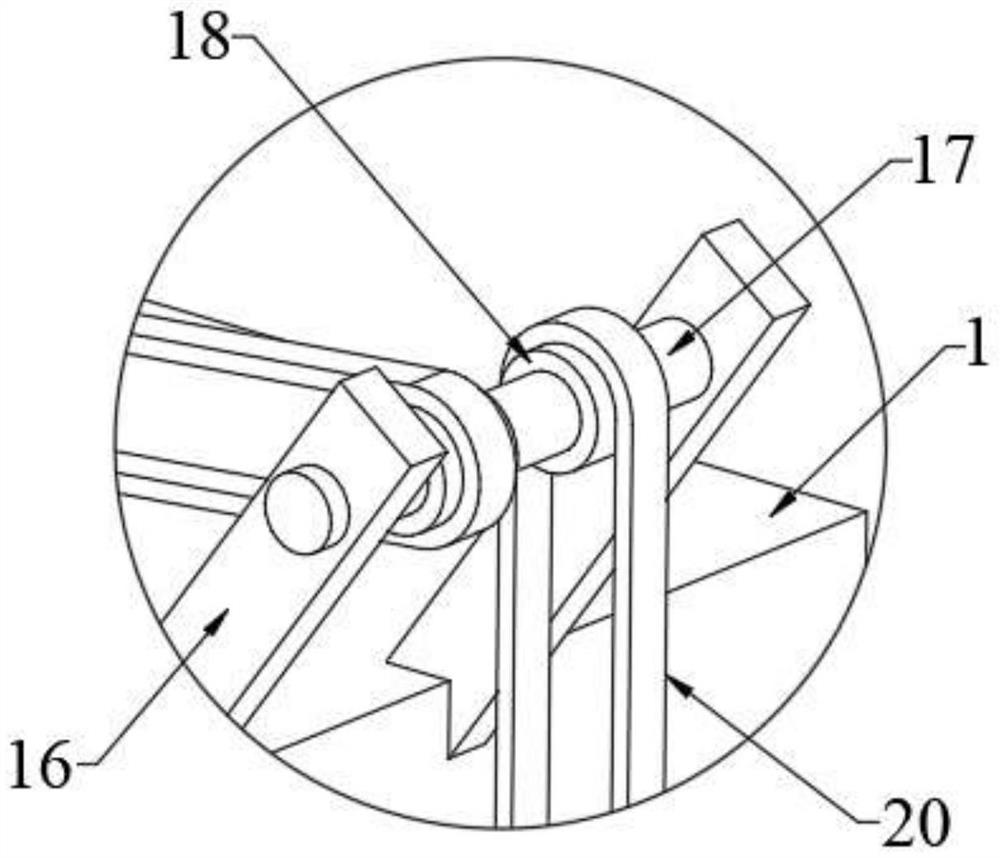

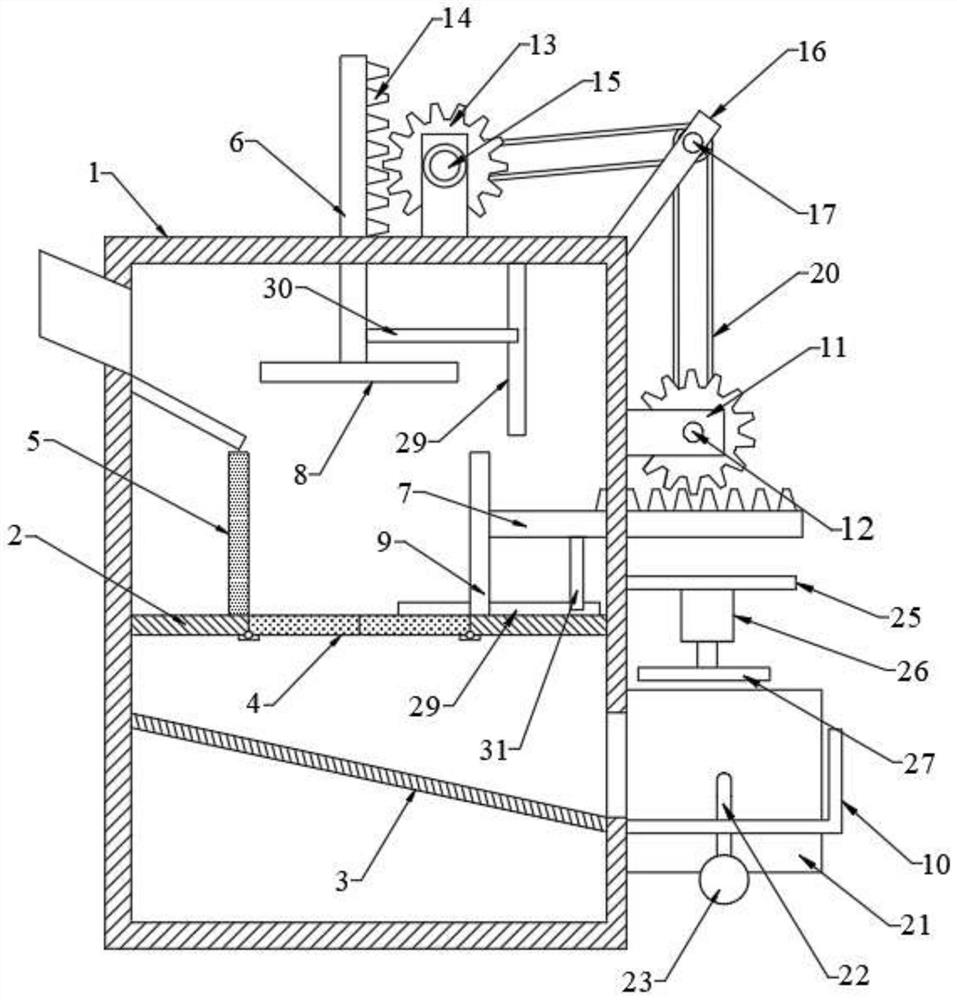

[0023] see figure 1 and Figure 3-4 , forage baler, including a treatment box 1, the inner wall of the treatment box 1 is fixedly connected with a partition 2 and a discharge guide plate 3, the middle part of the partition 2 is hinged with an opening and closing plate 4, the upper end of the partition 2 is fixedly connected with a baffle 5, and the processing box 1. The upper wall and the right wall are movably connected with the first moving rod 6 and the second moving rod 7 respectively, and the ends of the first moving rod 6 and the second moving rod 7 located inside the processing box 1 are respectively fixedly connected with the first extruding plate 8 and the second extruding plate 9, the upper wall and the right wall of the processing box 1 are connected with a transmission mechanism, the output end of the transmission mechanism is connected with the extruding plate 8 and the second extruding plate 9 respectively, and the outer wall of the processing box 1 A linkage me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com