Direct-drive consequent-pole permanent magnet hub motor

A wheel hub motor and alternating pole technology, which is applied in the direction of motors, magnetic circuits, electric components, etc., can solve the problems of air gap magnetic density asymmetry of alternating pole permanent magnet motors, solve the problem of unilateral magnetic flux leakage, and reduce electromagnetic rotation. Torque pulsation, the effect of saving the amount of permanent magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

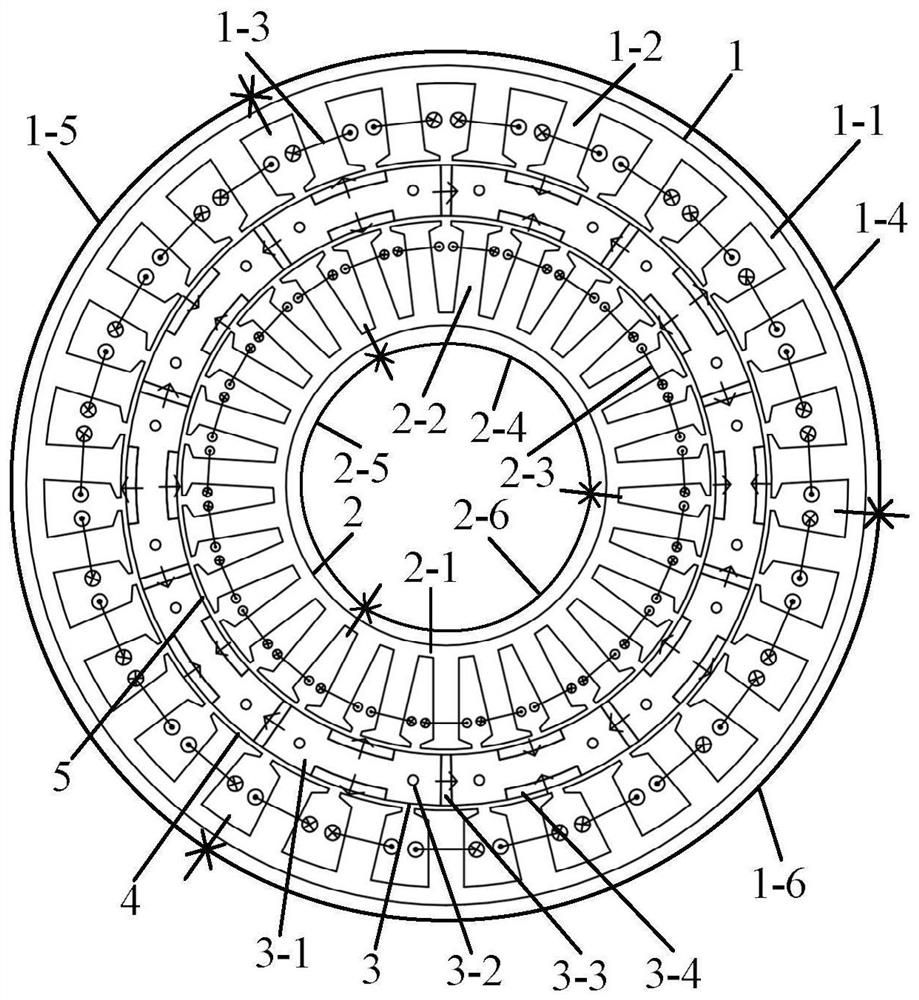

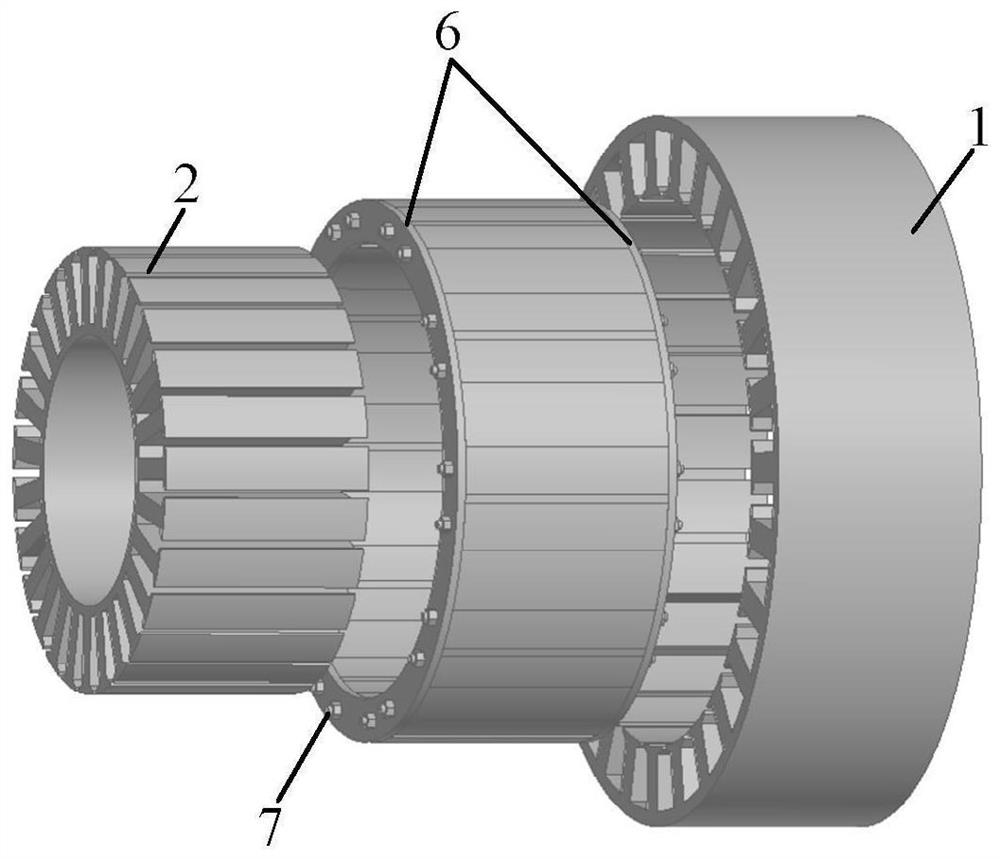

[0026] The present invention designs a direct drive alternating pole permanent magnet hub motor, such as figure 1 As shown, it includes the inner stator 2, the outer stator 1 and the alternating pole rotor 3 between them. The inner and outer stators 2 and 1 form independent air gaps 4 and 5 with the alternating pole rotor 3 respectively. The inner stator 2 and the outer Each stator tooth of the stator 1 is wound with armature windings 1-3 and 2-3, and the alternating pole rotor 3 includes several modular iron cores 3-1 and alternately arranged Spoke permanent magnets 3-3 and surface-mounted permanent magnets. The magnet 3-4, the Spoke permanent magnet 3-3 adopts circular magnetization, the surface-mounted permanent magnet 3-4 adopts radial magnetization, and the modular iron core 3-1 is provided with a positioning hole 3-2. Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com