A cast aluminum rotor tooth slot structure

A cast aluminum rotor and cogging technology, applied in the field of electric motors, can solve problems such as waste, and achieve the effects of improving motor efficiency, reducing rotor slot openings, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

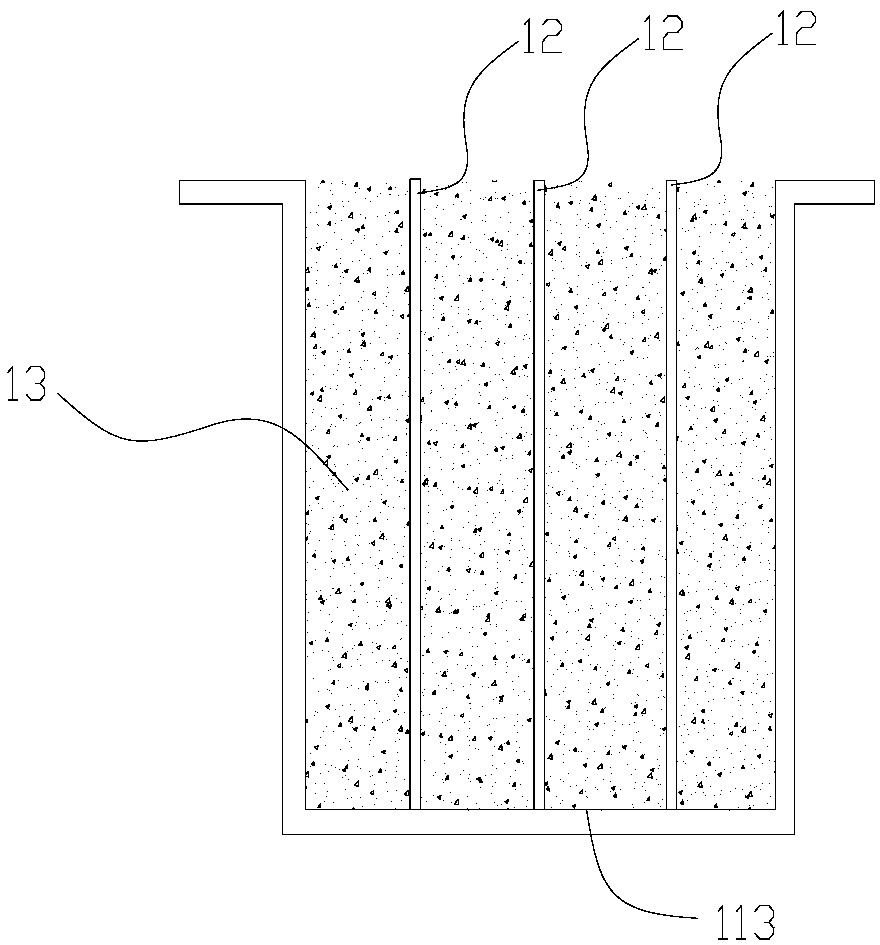

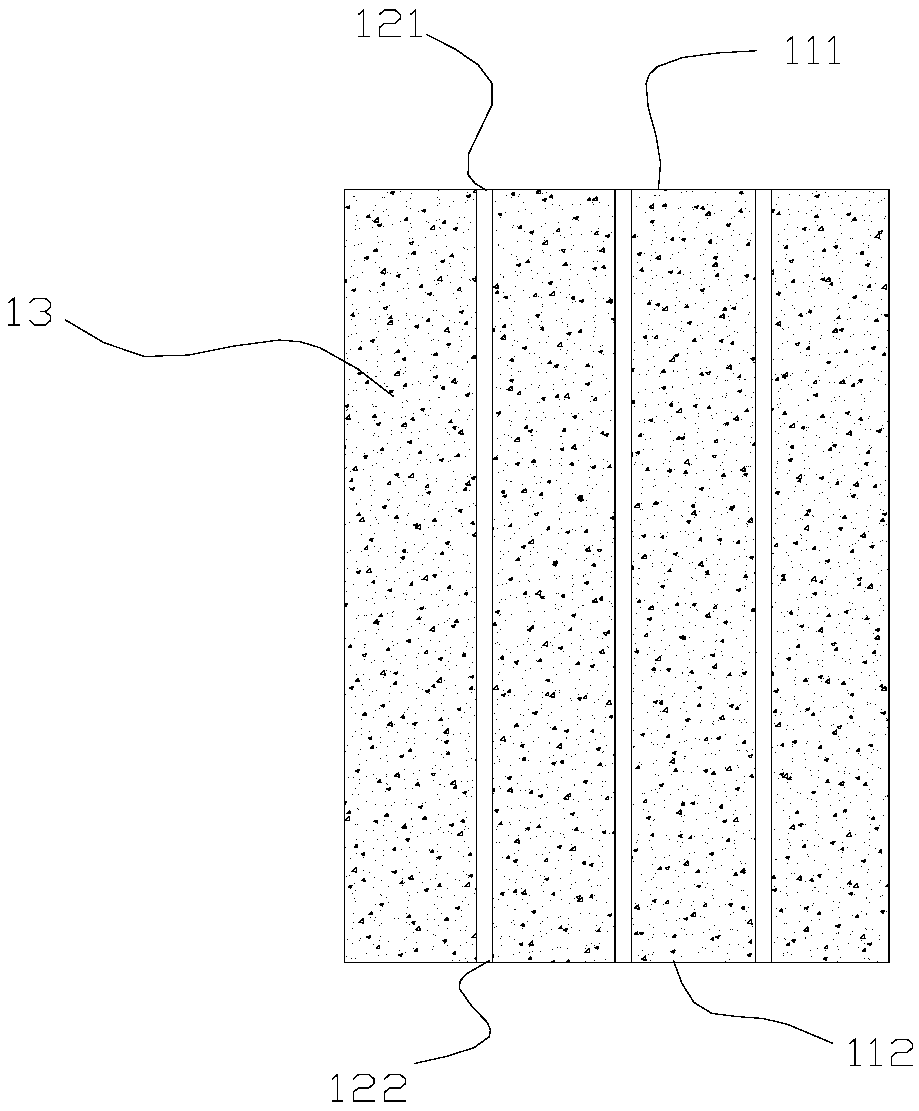

[0028] Such as figure 2 As shown, the present invention discloses a cast aluminum rotor alveolar structure, including an alveolar body, an insulating partition 12 is arranged in the cavity of the alveolar body; The wall 111 is connected or contacted, and the first end surface 121 extends to the second end surface 122 along the length direction of the alveolar body; the second end surface 122 is connected or contacted with the other end wall 112 of the alveolar body, and the bottom of the insulating partition 12 is in contact with the other end wall 112 of the alveolar body. The bottom wall 113 of the alveolar body is connected.

[0029] The present invention compares with figure 1 In the prior art shown, the width of the alveolar body is reduced by arranging an insulating partition 12 inside the alveolar body, according to the Ampere loop theorem It is known that under the condition of constant rotor current, by shortening r, the magnetic induction intensity is increased, ...

Embodiment 2

[0032] Such as figure 2 , 3 As shown, the present invention discloses a cast aluminum rotor alveolar structure, including an alveolar body, an insulating partition 12 is arranged in the cavity of the alveolar body; The wall 111 is connected or contacted, and the first end surface 121 extends to the second end surface 122 along the length direction of the alveolar body; the second end surface 122 is connected or contacted with the other end wall 112 of the alveolar body, and the bottom of the insulating partition 12 is in contact with the other end wall 112 of the alveolar body. The bottom wall 113 of the alveolar body is connected. The number of insulating partitions 12 is an odd number, and several insulating partitions 12 are equidistantly distributed. The central axis of the middlemost insulating partition 12 coincides with the central axis of the alveolar body.

[0033] The electromagnetic torque of the initial non-segmented cast aluminum groove is set to an index of 1...

Embodiment 3

[0039] Such as figure 2 , 3 As shown, the present invention discloses a cast aluminum rotor alveolar structure, including an alveolar body, an insulating partition 12 is arranged in the cavity of the alveolar body; The wall 111 is connected or contacted, and the first end surface 121 extends to the second end surface 122 along the length direction of the alveolar body; the second end surface 122 is connected or contacted with the other end wall 112 of the alveolar body, and the bottom of the insulating partition 12 is in contact with the other end wall 112 of the alveolar body. The bottom wall 113 of the alveolar body is connected.

[0040] The bottom wall 113 of the alveolar body is provided with a slot (not shown in the figure), and the bottom of the insulating partition 12 is engaged in the slot or the bottom wall 113 of the alveolar body is bonded to the bottom of the insulating partition 12 by an adhesive. combine.

[0041] The insulation partition 12 is pre-positione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com