Combined type current-limiting venturi tube suitable for CVS and machining method of combined type current-limiting venturi tube

A venturi tube and combined technology, applied in the field of machinery, petrochemical equipment, and nuclear power equipment, can solve the problems of reduced flow control accuracy, long replacement cycle, and high pipeline flow rate, so as to avoid leakage risks, ensure service life, and improve processing technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

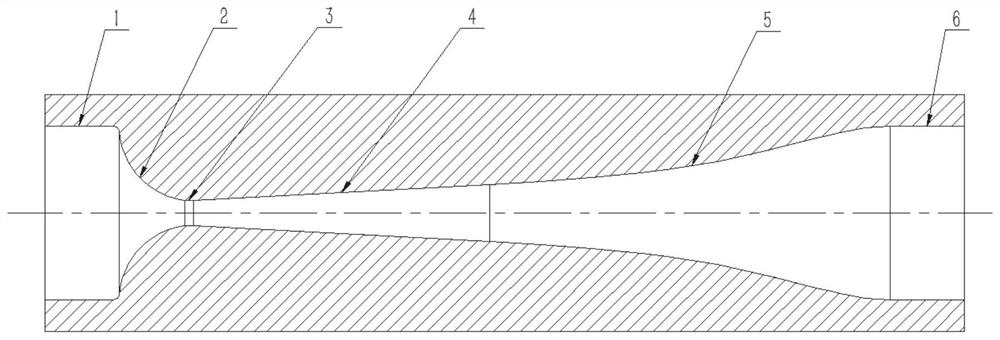

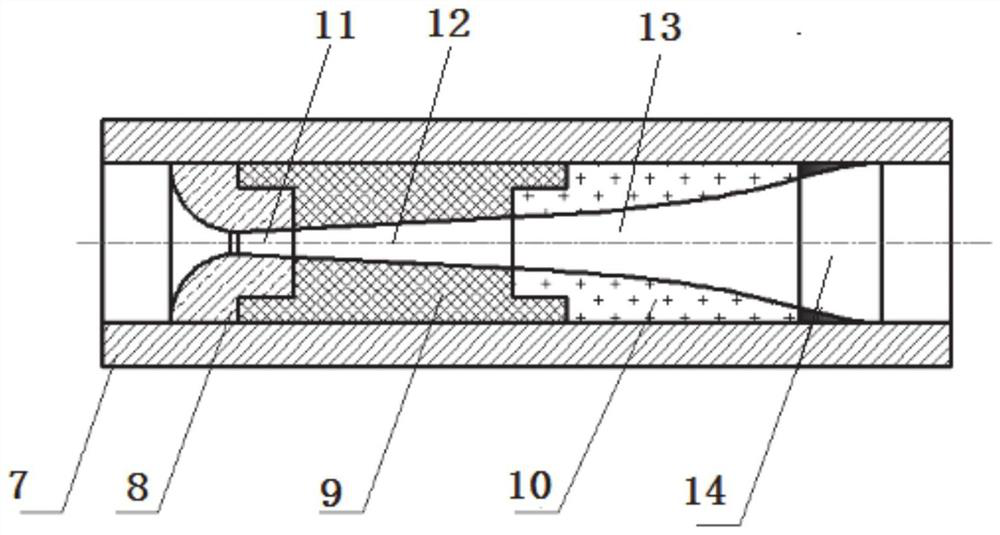

[0048] In a typical embodiment of the invention, reference Figure 1 - Figure 2 As shown, a combination of CVS is limited to the CVS, including the pipe body 7, the pipe body 7 in hollow, along the length direction of the pipe body, is sequentially assembled with assembly section in the pipe. The position of the assembly section can be adjusted in the position of the pipe. The total length of the assembled section is less than or equal to the length of the pipe body 7, so that according to the assembly section, the assembly section can be adjusted and positioned within the length of the pipe main body, and realizes the inlet straight pipe section and The length of the export straight pipe section is adjusted, and the inside of the assembly section forms all or part of the flow passage inside the venturi tube, at least one of the assembly segments can be detachably connected, and the cylindrical tube section of the flow channel inside this segment is 3. Connect the same as the cylin...

Embodiment 2

[0060] The present invention also provides a method of processing a combined current flow cyclonic tube suitable for CVS, such as figure 2 As shown, including the following:

[0061] The first paragraph 8, sections 2 9, and the third segment 10 can be completed in the first segment 8, the second paragraphs, and the third segment 10, using the shaft hole tolerance, to ensure the smoothness of the inner surface hydraulic curve, the pipe body 7 can be processed with inner hole boring, first according to The length of the inlet straight pipe section 1 and the outlet straight pipe section 6 in the pipe body 7 are positioned as the positioning reference, and the first segment is assembled in the second section of the first segment 8, and the first segment is assembled. The other end of the second paragraph is assembled with the third paragraph, and the specific assembly mode is the concave portion of the second segment with the first segment and the convex portion engagement fit.

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com