Rock fracture seepage-temperature coupling visual test system and test method

A technology of rock fissure and test system, which is applied in the field of rock mechanics test, can solve the problems such as the seepage problem and heat conduction problem that cannot be considered, and achieve the effects of controllable monitoring error, high installation accuracy, and safe and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and implementation example the present invention is further described:

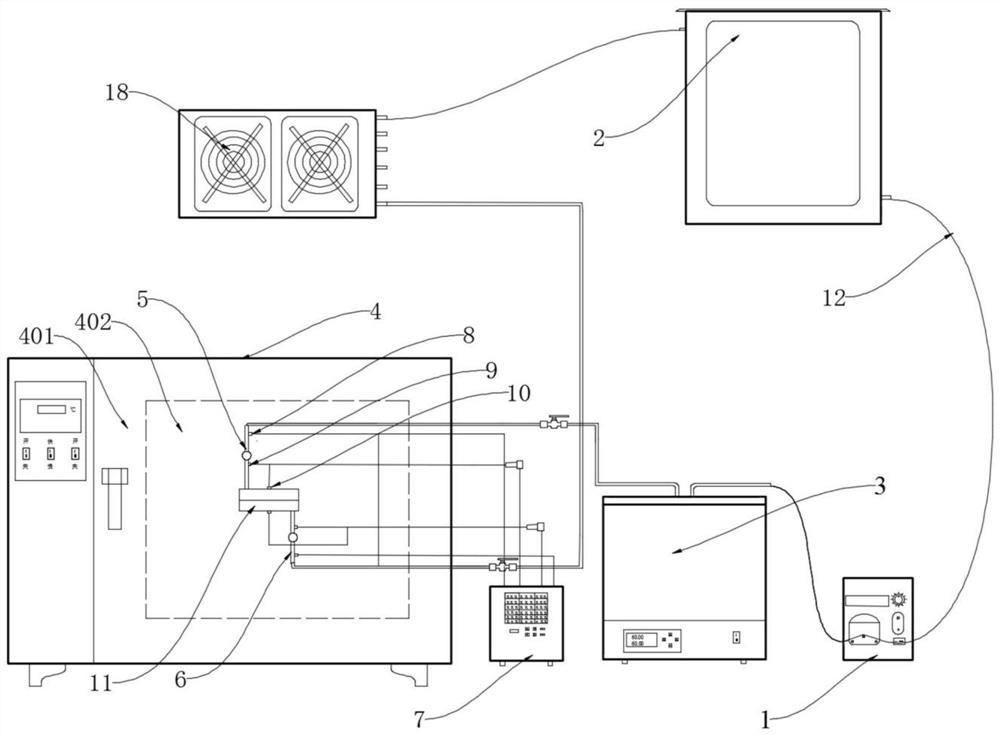

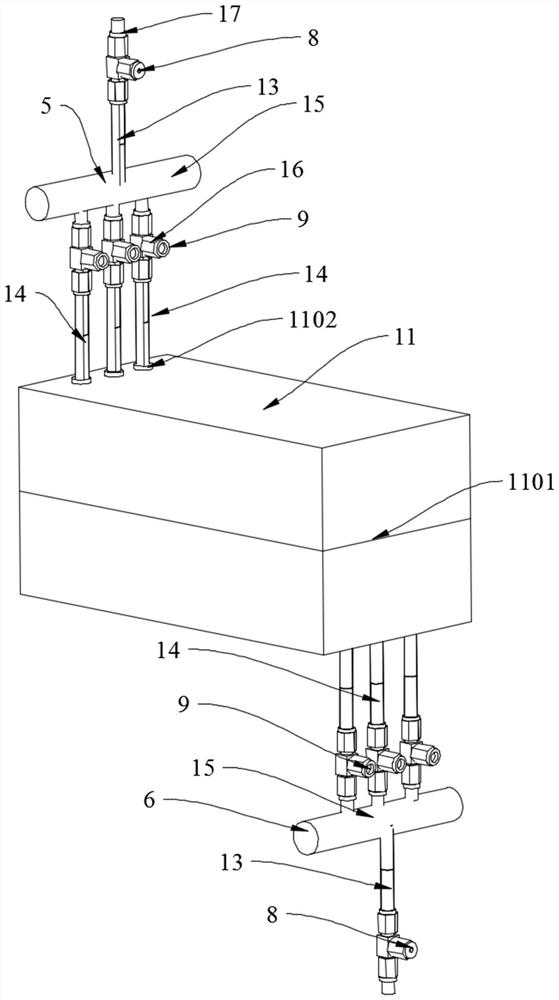

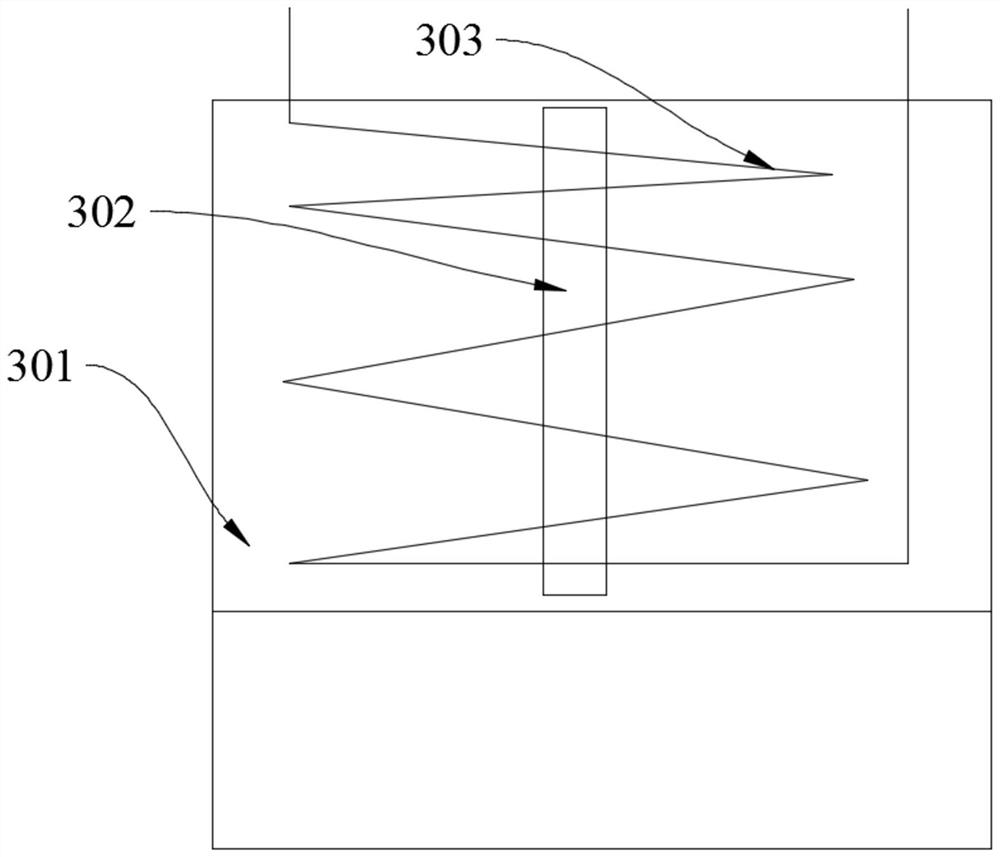

[0046] Such as Figure 1 to Figure 3 As shown, the present invention provides a visual test system of rock fissure seepage-temperature coupling, including a water storage tank 2, a water pump, a liquid preheater 3, a constant temperature box 4, a transmission cross flow pipe, a liquid radiator 18, a data acquisition device and Rock fracture sample 11;

[0047] The rock fissure sample 11 is placed in the incubator 4, and the incubator 4 is provided with at least one transparent window 402 for observing seepage in the fissure; and the downstream transmission fork flow pipe 6, the upstream transmission fork flow pipe 5 is installed on the inflow end of the rock fissure sample 11, the downstream transmission fork flow pipe 6 is installed on the outflow end of the rock fissure sample 11, and each transmission fork flow pipe has A pressure sensor 9 and a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com