Punching device and punching method

A punching device and punching technology, which is applied in the fields of drilling and flushing, and punching devices, can solve problems such as the collapse of the cutting surface ore layer, and achieve the effect of improving the punching effect and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

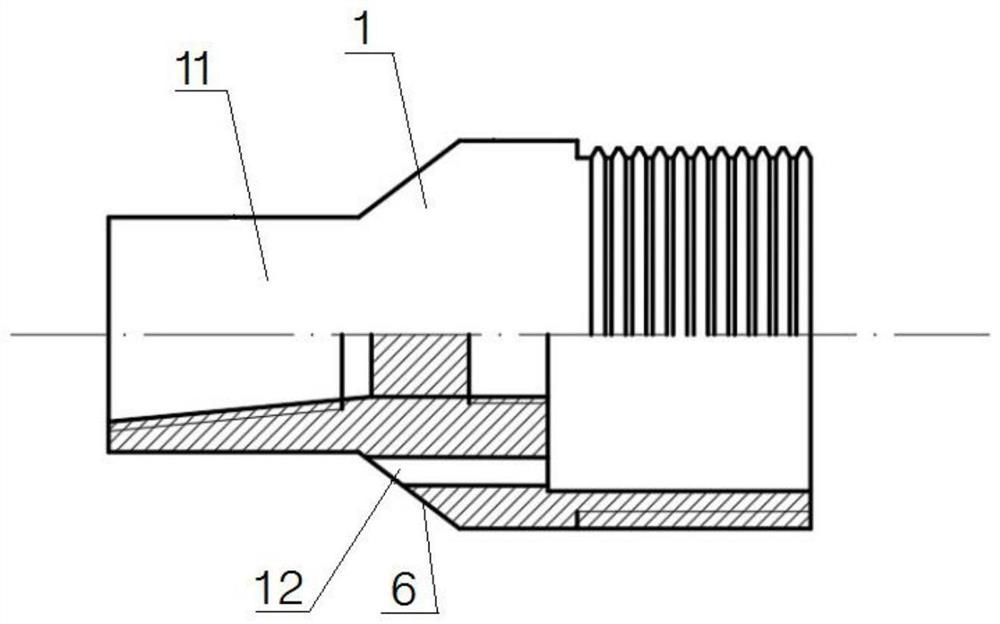

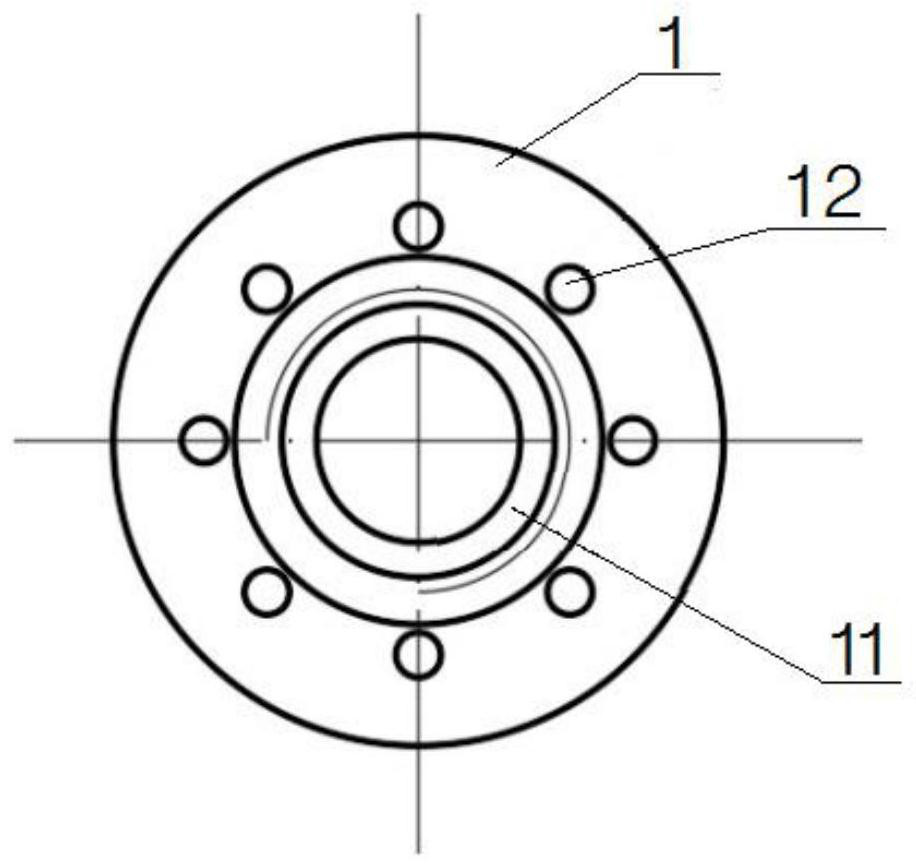

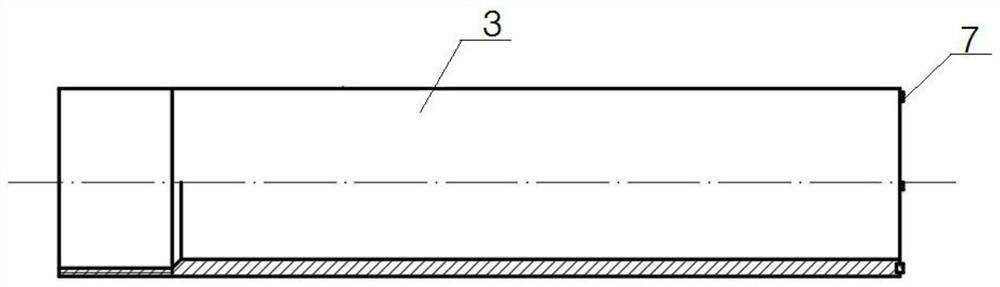

[0053] Such as Figure 1-6As shown, this embodiment provides a punching device 100, specifically a punching device that can satisfy the secondary well-forming process of cutting and constructing filters. It mainly includes an adapter 1, a flushing pipe 2 and an outer Protective tube 3. The adapter 1 is provided with a liquid inlet flow channel 11 and a liquid outlet flow channel 12, and the liquid inlet flow channel 11 and the liquid outlet flow channel 12 are arranged at intervals; one end of the adapter 1 is used to connect with the lowering part. The flushing pipe 2 is connected with the other end of the adapter 1, so as to introduce the punching liquid in the liquid inlet channel 11 into the borehole to be flushed, and perform punching. The outer protective tube 3 is connected to the other end of the adapter 1, and the outer protective tube 3 is sleeved on the outer periphery of the flushing tube 2, and an annular liquid outlet cavity 4 is formed between the outer protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com