Dyeing nylon yarn, preparation method thereof and textile product

A technology for textile products and nylon yarns, applied in the field of dyed nylon yarns and its preparation method, and textile products, which can solve the problems of unqualified products and prone to color flowers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

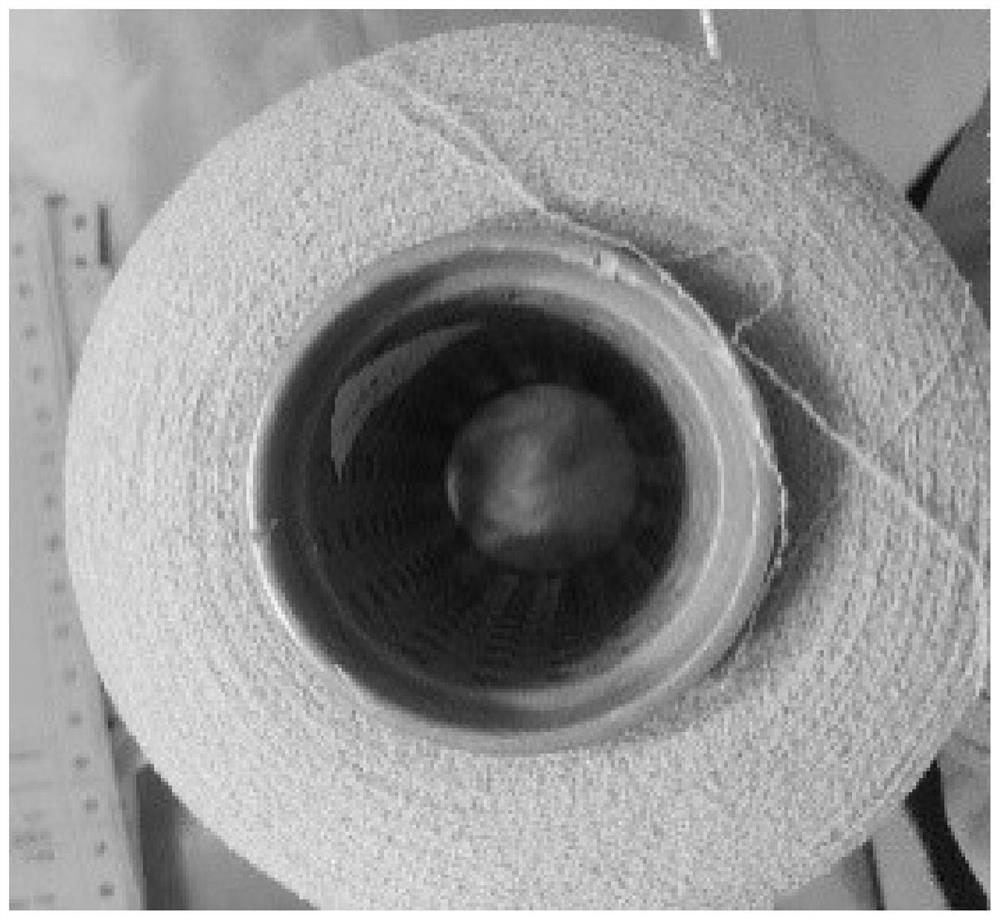

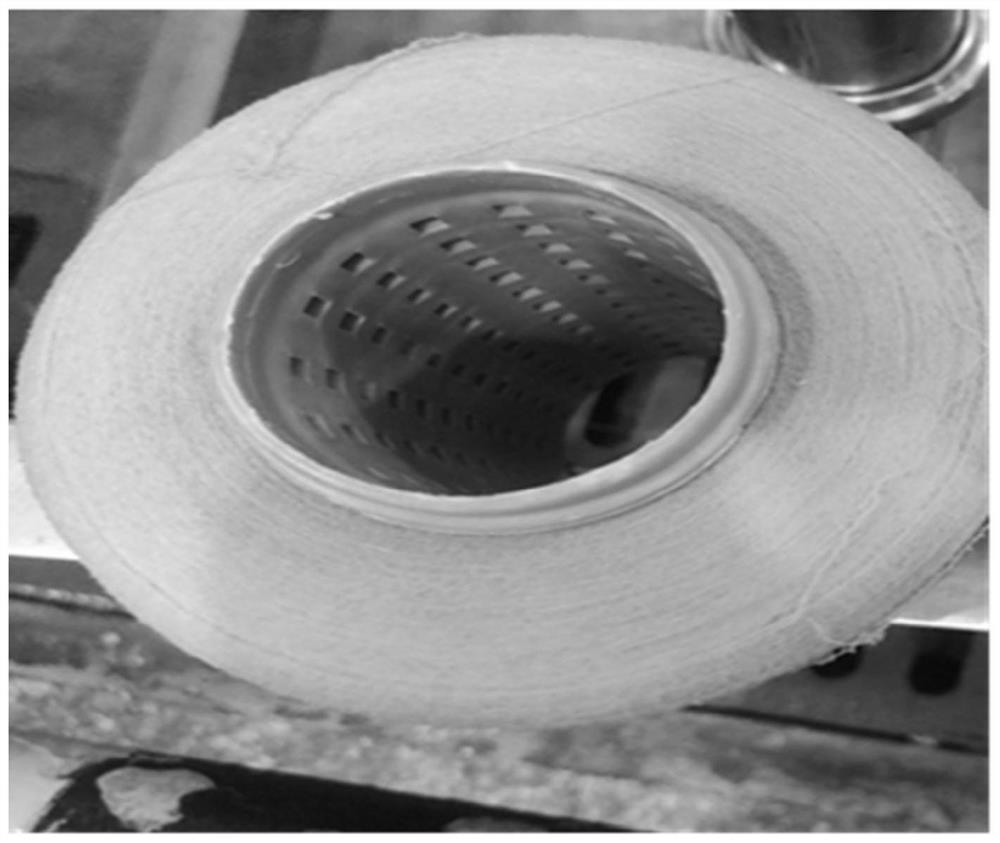

Image

Examples

preparation example Construction

[0034] One embodiment of the present invention provides a method for preparing dyed nylon yarn, which includes the following step S10.

[0035] Step S10, performing scouring treatment on the undyed nylon yarn, and then performing dyeing treatment and soaping treatment in sequence to obtain dyed nylon yarn.

[0036] The above dyeing step includes the following step S11.

[0037] Step S11. Dip the refined nylon yarn in the aqueous solution of ERIOFAST reactive dye at 40°C to 45°C, perform the first dyeing treatment for not less than 15 minutes, and then add calcium chloride to continue for not less than 5 minutes After the second dyeing treatment, add acetic acid and sodium acetate to continue the third dyeing treatment for no less than 5 minutes; then raise the temperature to 55°C-98°C and continue the fourth dyeing treatment for no less than 50 minutes;

[0038] Among them, the OWF of ERIOFAST reactive dyes is less than 1.0%.

[0039] In the preparation method of the above-m...

Embodiment 1

[0090] (1) Dye a cylinder of 70D (40D) nylon elastic cheese in a dyeing cylinder with a diameter of 1800mm, the yarn weight is 425kg, and the liquor ratio is 1:11.

[0091] (2) After the nylon elastic cheese yarn is put into the vat, enter clean water, add refining agent EPDC010.9g / L, heat up to 85°C, refine for 20 minutes, drain, then enter clean water, wash at room temperature for 5 minutes, and then drain.

[0092] (3) Dyeing: advance water, control the temperature at 45°C, and then add the dyes of the following formula: wherein, the total OWF of ERIOFAST reactive dyes is 0.332%.

[0093] ERIOFAST BLUE 3R: 0.18%

[0094] ERIOFAST YELLOW R: 0.08%

[0095] ERIOFAST RED 2B: 0.072%

[0096] At 45°C, dye for 20 minutes first, then add calcium chloride (concentration: 10g / L), continue dyeing for 15min, then add HAC (concentration: 0.5g / L) and NaAC (concentration: 2g / L) ), continue the dyeing process for 15 minutes.

[0097] Then raise the temperature to 55°C and continue the ...

Embodiment 2

[0101](1) Dye a cylinder of 70D (40D) nylon elastic cheese in a dyeing cylinder with a diameter of 1400mm, the yarn weight is 235.2kg, and the liquor ratio is 1:12.5.

[0102] (2) After the nylon elastic cheese yarn is put into the vat, enter clean water, add 1.2g / L refining agent, raise the temperature to 90°C, drain after refining for 20 minutes, then enter clean water, wash with water at room temperature for 5 minutes, and then drain.

[0103] (3) Dyeing: advance water, control the temperature at 45°C, and then add the dyes of the following formula: wherein, the total OWF of ERIOFAST reactive dyes is 0.523%.

[0104] ERIOFAST BLUE 3R: 0.338%

[0105] ERIOFAST YELLOW R: 0.128%

[0106] ERIOFAST RED 2B: 0.057%

[0107] At 45°C, dye for 15 minutes, then add calcium chloride (concentration: 10g / L), continue dyeing for 10min, then add HAC (concentration: 0.3g / L) and NaAC (concentration: 2g / L) ), continue the dyeing process for 10 min.

[0108] Then raise the temperature to 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com