Double-yarn air-spliced high-color-fastness polyester staple fiber and preparation method

A polyester staple fiber, high color fastness technology, applied in the dyeing method, fiber treatment, hollow filament manufacturing, etc., can solve the problems of color flowering, accelerated adsorption rate, low color fastness of polyester staple fiber dyeing, etc., to achieve enhanced Fiber elasticity, increase the contact area, and avoid the effect of color and flower problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

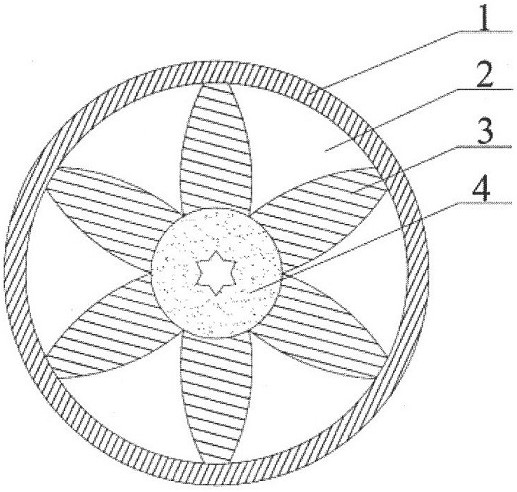

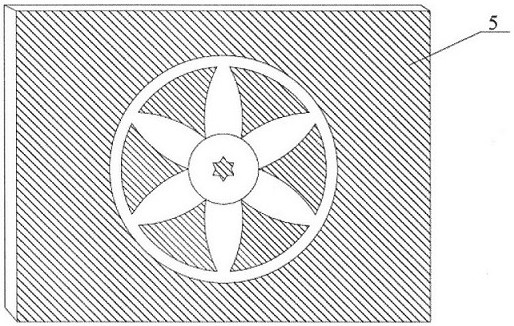

[0025] The invention provides a kind of high color fastness polyester staple fiber and preparation method of double yarn air splicing, refer to figure 1 , the process flow diagram of the preparation process of high color fastness polyester staple fiber of double yarn air splicing provided by a specific embodiment of the present invention, the process comprises the following steps:

[0026] a) Mix and stir dimethyl phthalate, ethylene glycol, polypropylene glycol, and potassium hydroxide, heat up until methanol distills, control the reaction temperature at 170°C to 180°C, and wait for the amount of methanol to be distilled to be 93% of the theoretical amount %~97%, the transesterification reaction is over. Add dipropylene glycol isophthalate-5-sodium sulfonate (1% to 3% of the total mass of dimethyl phthalate), ethylene glycol antimony and Mn(OAc)2 blend system, and introduce sodium sulfonate Dye seat, so as to combine with cationic dyes, introduce the meta-position structure...

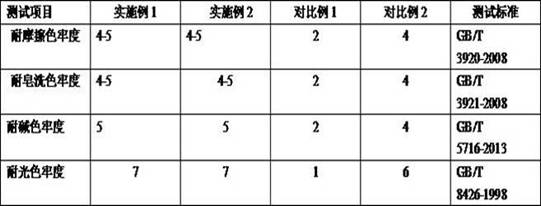

example 1

[0030] a) Mix and stir dimethyl phthalate, ethylene glycol, polypropylene glycol, and potassium hydroxide, heat up until the methanol distills out, control the reaction temperature at 170°C, and wait for the distilled amount of methanol to be 93% of the theoretical amount. The exchange reaction is complete. Add dipropylene glycol isophthalate-5-sodium sulfonate (1% of the total mass of dimethyl phthalate), ethylene glycol antimony and Mn(OAc)2 blend system, and introduce sodium sulfonate dye base, In this way, it combines with cationic dyes, introduces meta-position structure, destroys the regular structure of macromolecules, and makes dye molecules easy to enter polyester. When the temperature of the kettle reaches 230°C, depressurize the system, and gradually raise the temperature of the kettle to 280°C, and control the vacuum pressure below 80 Pa for 1.42 hours. After the reaction is completed, pressurize with nitrogen and discharge the material.

[0031]b) Dry by hot air ...

example 2

[0034] a) Mix and stir dimethyl phthalate, ethylene glycol, polypropylene glycol, and potassium hydroxide, heat up until methanol distills out, control the reaction temperature at 180°C, and wait until the amount of methanol distilled is 97% of the theoretical amount. The exchange reaction is complete. Add dipropylene glycol isophthalate-5-sodium sulfonate (3% of the total mass of dimethyl phthalate), ethylene glycol antimony and Mn(OAc)2 blend system, and introduce sodium sulfonate dye base, In this way, it combines with cationic dyes, introduces meta-position structure, destroys the regular structure of macromolecules, and makes dye molecules easy to enter polyester. When the temperature of the kettle reaches 240°C, depressurize the system, and gradually raise the temperature of the kettle to 290°C, and control the vacuum pressure below 100 Pa for 1.42 hours. After the reaction is completed, pressurize nitrogen and discharge the material.

[0035] b) Dry by hot air flow. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com