Blade section line adaptive reconstruction method based on on-machine measurement

A cross-section line and self-adaptive technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems such as the self-adaptive reconstruction method of the blade cross-section line, so as to improve the processing quality and improve the processing quality. Efficiency, the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

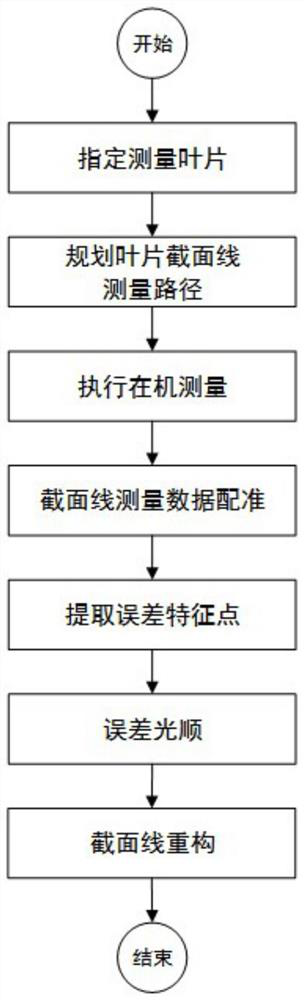

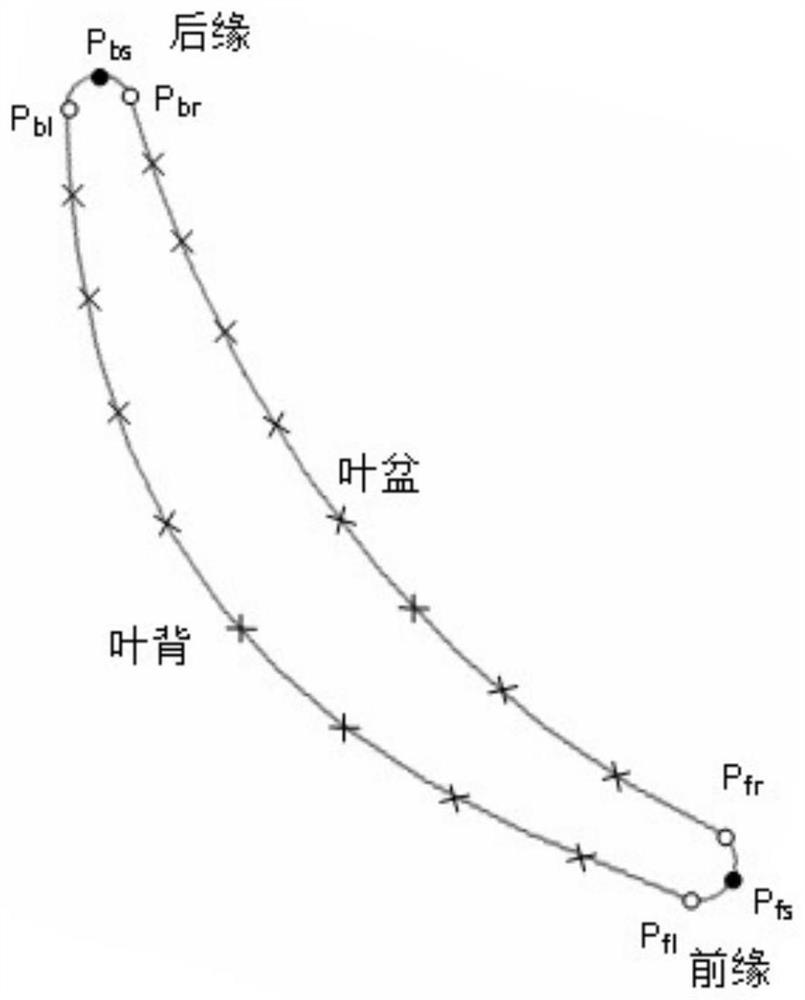

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the figure, an adaptive reconstruction method for blade cross-section lines based on on-machine measurement, an adaptive reconstruction method for blade cross-section lines based on on-machine measurement, and measurement based on blade planning cross-section lines Path, perform on-machine measurement, and register the measurement data, adaptively extract error feature points and error smoothing, calculate section line points, and interpolate to obtain section lines;

[0030] Flowchart of adaptive reconstruction method of blade section line based on on-machine measurement, such as figure 1 shown;

[0031] The steps of adaptive reconstruction of blade section line based on on-machine measurement are as follows:

[0032] 1) Import the overall blisk geometry model in igs or step format, specify the blade surface to be measured, and define it as measurement b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com