Steel slag processing technology

A treatment process and technology for steel slag, applied in the field of steel slag processing technology, can solve problems such as occupation of cultivated land, low utilization rate of steel slag, environmental pollution, etc., and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

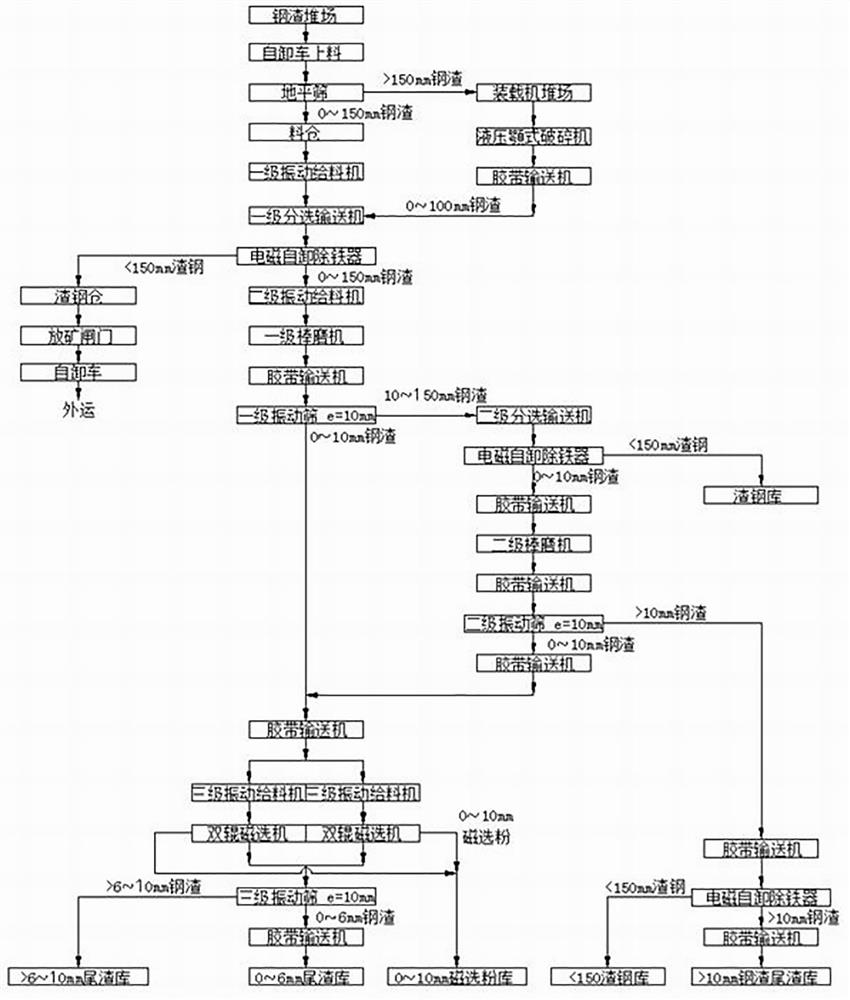

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

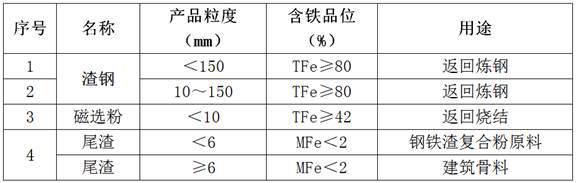

[0021] The steel slag processing technology in this embodiment, combined with the characteristics of the steel slag raw material of a steel factory, is designed to adopt the most advanced rod mill, screening, and magnetic separation equipment in China, so that the metallic iron in the steel slag can be separated and recycled to the greatest extent. TFe≥80% for steel slag larger than 10mm; TFe≥40% for 0-10mm magnetic separation powder. Based on the annual processing of 3.3 million tons of steel slag, 214,500 tons of slag steel and 544,500 tons of magnetic separation powder can be recycled each year. The recovery of metallic iron saves an equal amount of natural resources and the corresponding energy consumption of steelmaking.

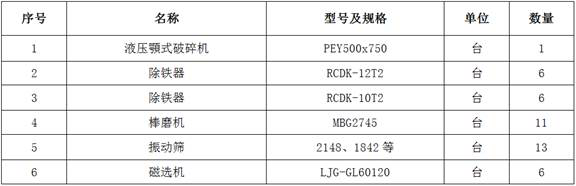

[0022] Main equipment selection:

[0023]

[0024] Product solutions:

[0025]

[0026] Main supporting projects:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com