Device for trapping hydrogen

A technology of degassing device and circulation device, which is applied in the field of quantitative devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

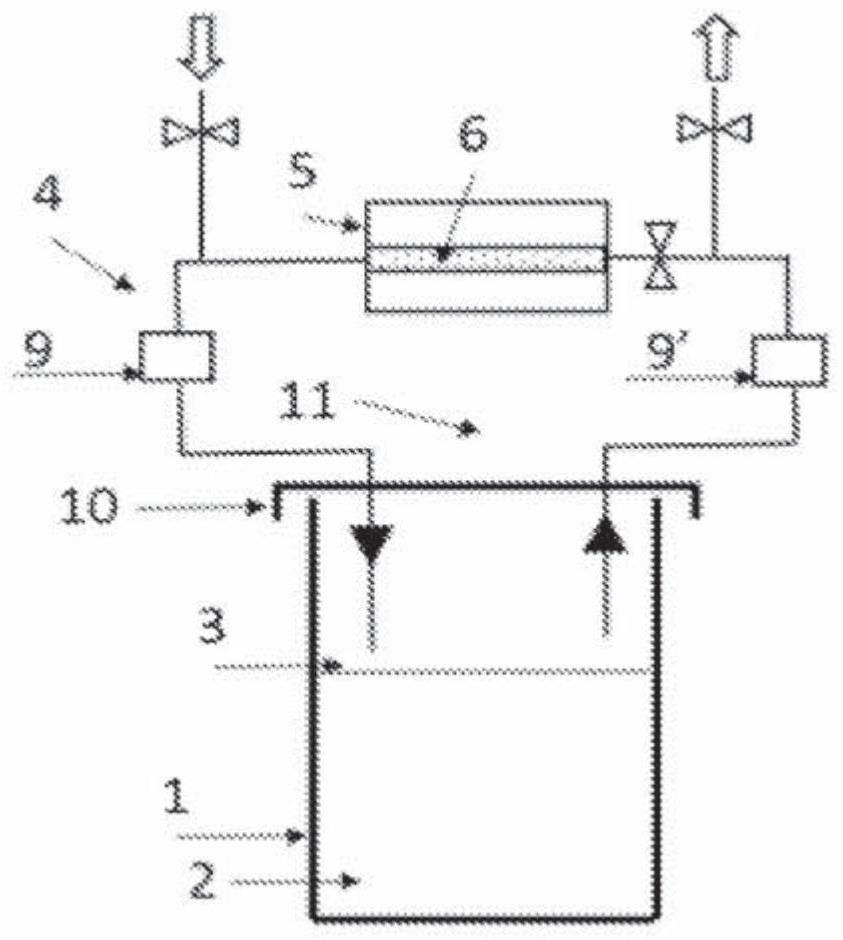

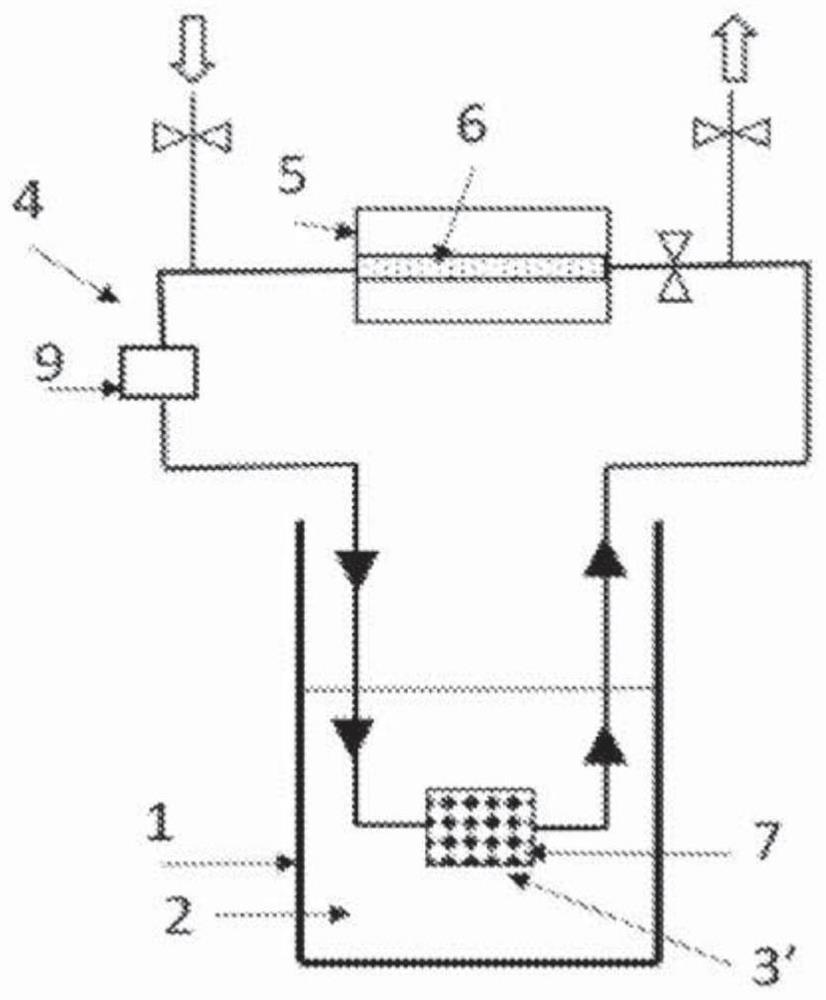

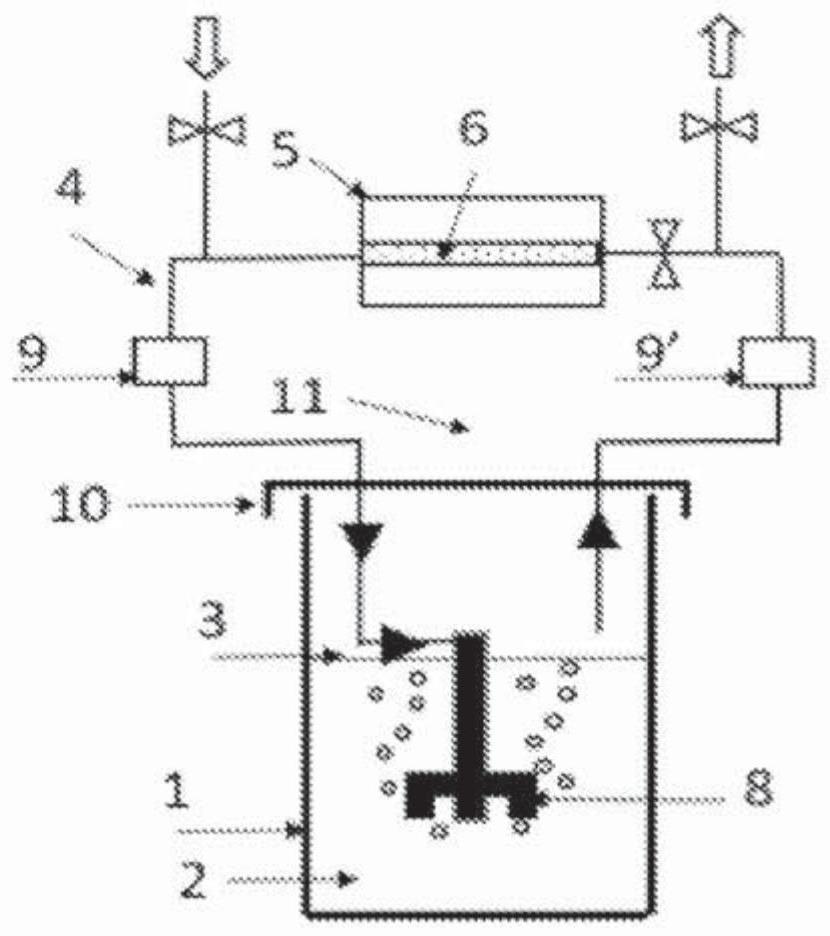

[0056] For the study of liquid metals with passage through ceramic exchangers such as figure 2 The exchange kinetics between the cycle gases used in the configuration of ), the following experiments were carried out.

[0057] 10 kg of an aluminum alloy of type AG5 - consisting of 5% magnesium and 95% aluminum and 5 ppm beryllium - was melted in a graphite clay crucible at a temperature of about 700°C. With the help of a pressure regulator, the industrial argon gas can be used at a flow rate of D Ar Circulation through an exchanger submerged in liquid metal at a regulated pressure of 1.2 bar.

[0058] The exchanger is a porous material made of SiC ceramic foam. Two geometries were tested; the first exchanger had dimensions 50x50x25mm and an apparent exchange surface area of 87.5cm 2 , while the second exchanger has dimensions of 100x100x25mm and an apparent exchange surface area of 275cm 2 . The SiC ceramic foam is drilled to introduce stainless steel tubes for argon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com