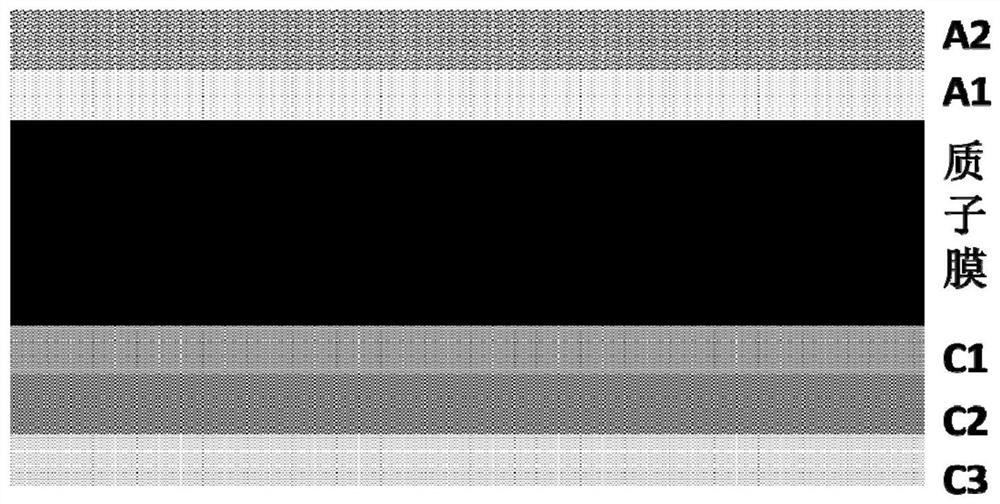

Membrane electrode of gradient proton exchange membrane fuel cell as well as preparation method and application of membrane electrode

A proton exchange membrane, fuel cell membrane technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems of catalyst waste, uneven distribution of catalytic layers, poor utilization, etc., to increase gas transmission channels and reduce interface effects. , the effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

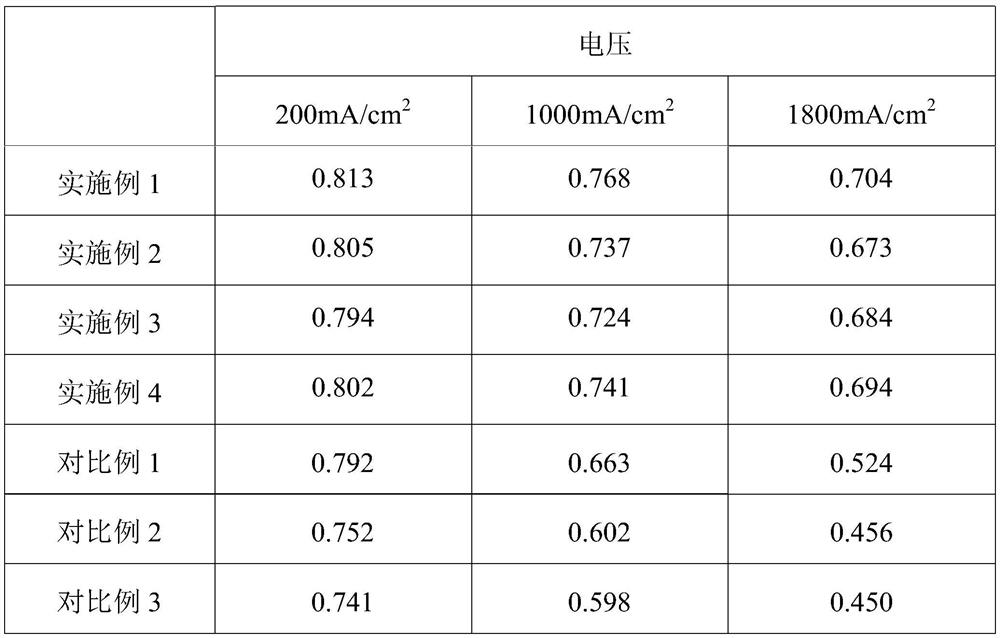

Embodiment 1

[0068] This embodiment provides a gradient proton exchange membrane fuel cell membrane electrode, comprising the following steps:

[0070] (a) Prepare the first layer of catalyst slurry, take by weighing 100mg of platinum-carbon catalyst with a platinum content of 30%, add 25g of deionized water, then add dropwise the solution containing 35mg of ionomer (concentration is 3%, EW value is 800) For the ionomer solution, make carbon: polymer = 1:0.5, add 28 g of isopropanol dropwise after ultrasonication in an ice bath, and mix evenly with ultrasonication in an ice bath. Use a high-speed emulsifying shearing machine to carry out strong dispersion for 40 minutes to obtain the catalyst ink to be sprayed, and the dispersion speed is 20000r / min. Wherein the percentage of platinum in the slurry solid content is 22.2%.

[0071] (b) Prepare the second layer of catalyst slurry, take by weighing 100mg of platinum-carbon catalyst with a platinum content of ...

Embodiment 2

[0078] This embodiment provides a gradient proton exchange membrane fuel cell membrane electrode, comprising the following steps:

[0079] Anode catalyst slurry:

[0080](a) Prepare the first layer of catalyst slurry, take by weighing 100mg of platinum-carbon catalyst with a platinum content of 20%, add 25g of deionized water, then add dropwise the solution containing 96mg of ionomer (concentration is 1%, EW value is 900) For the ionomer solution, make carbon: polymer = 1:1.2, add 28 g of isopropanol dropwise after ultrasonication in an ice bath, and mix evenly with ultrasonication in an ice bath. Use a high-speed emulsifying shearing machine to carry out strong dispersion for 40 minutes to obtain the catalyst ink to be sprayed, and the dispersion speed is 20000r / min. Wherein the percentage of platinum in the slurry solid content is 10.2%.

[0081] (b) prepare the second layer of catalyst slurry, take by weighing 100mg of platinum-carbon catalyst with a platinum content of 3...

Embodiment 3

[0088] This embodiment provides a gradient proton exchange membrane fuel cell membrane electrode, the specific preparation method is as follows:

[0089] Anode catalyst slurry:

[0090] (a) Prepare the first layer of catalyst slurry, take 25mg of platinum-carbon catalyst with a platinum content of 30%, add 25g of deionized water, and then add 24.5mg of ionomer dropwise (concentration is 20%, EW value is 820) For the ionomer solution, make carbon:polymer = 1:1.4, add 28g of isopropanol dropwise after ultrasonication in an ice bath, and mix evenly with ultrasonication in an ice bath. Use a high-speed emulsifying shearing machine to carry out strong dispersion for 40 minutes to obtain the catalyst ink to be sprayed, and the dispersion speed is 20000r / min. The percentage of platinum in the slurry solid content is 15.2%

[0091] (b) prepare the second layer of catalyst slurry, take by weighing 25mg of platinum-carbon catalyst with a platinum content of 20%, add 25g of deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com