Geoplane calibration device and method based on spherical triangle geometric theory

A laser sweeper, spherical triangle technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of lowering, occupying a large area, unable to calibrate the sweeping error, etc., to improve repeatability, reduce floor space requirements, and improve calibration accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

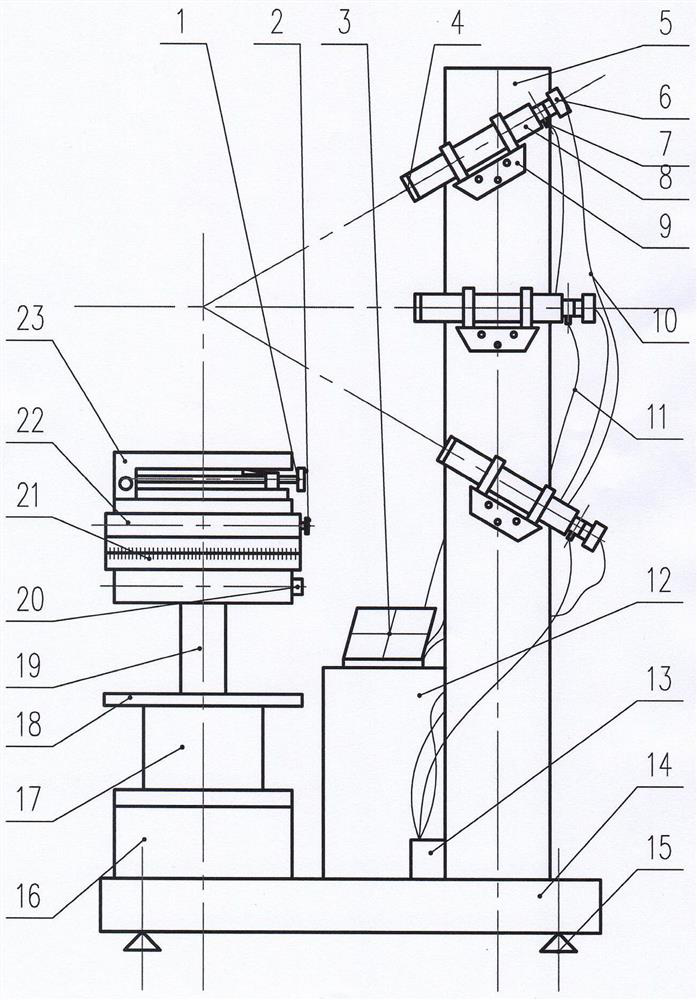

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] When this embodiment is in use, one end of the platform is provided with a lifting workbench, a 360° rotating workbench is fixed on the lifting workbench, and a translation workbench with a stroke of not less than 50mm is set up on the turntable, and the inclination range of the translation workbench is ±2.5mm. ° Slightly inclined workbench; the other end of the platform is equipped with a column, and three supports are installed on the column at three positions symmetrically distributed at 0° horizontally and ±30° inclined, and three long focal length parallel lights are erected on the three supports. The front end of each collimated light tube is equipped with a light-reducing filter group. The focal plane of the light tube is provided with a two-dimensional scale reticle. Behind the reticle is fixed an illuminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com