Plastic bottle recycling auxiliary device for solid waste treatment

A solid waste and auxiliary device technology, applied in the direction of plastic recycling, recycling technology, presses using rotating pressure members, etc., can solve problems such as insufficient extrusion, large volume, thick thickness, etc., to achieve processing quality assurance, High degree of automation, the effect of slowing down the running speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

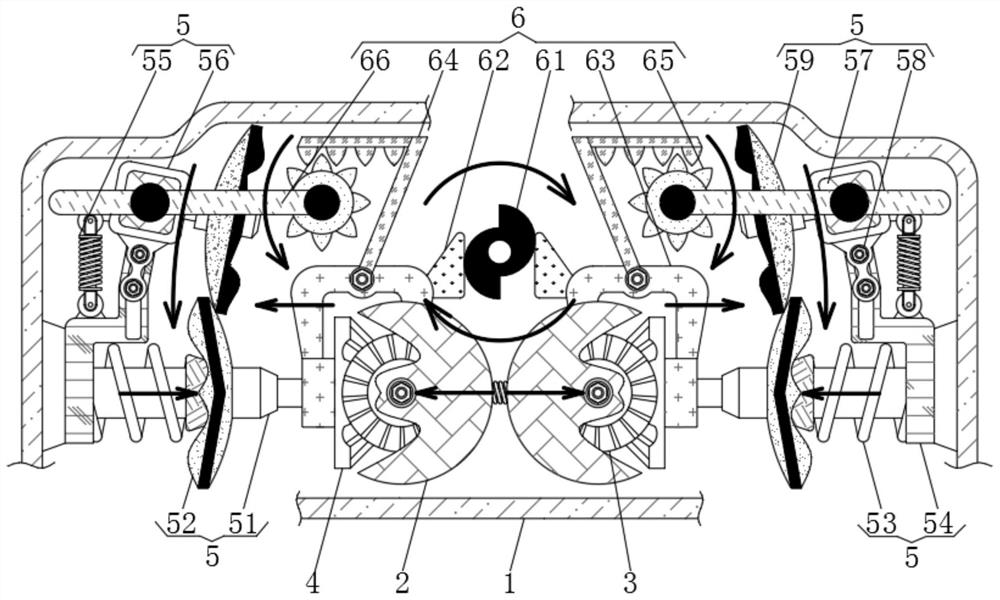

[0024] see Figure 1-3 , a plastic bottle recovery auxiliary device for solid waste treatment, comprising a shell 1, a hot roller 2, a cone wheel 3, a cone wheel 2 4, a drive mechanism 5 and an adjustment mechanism 6.

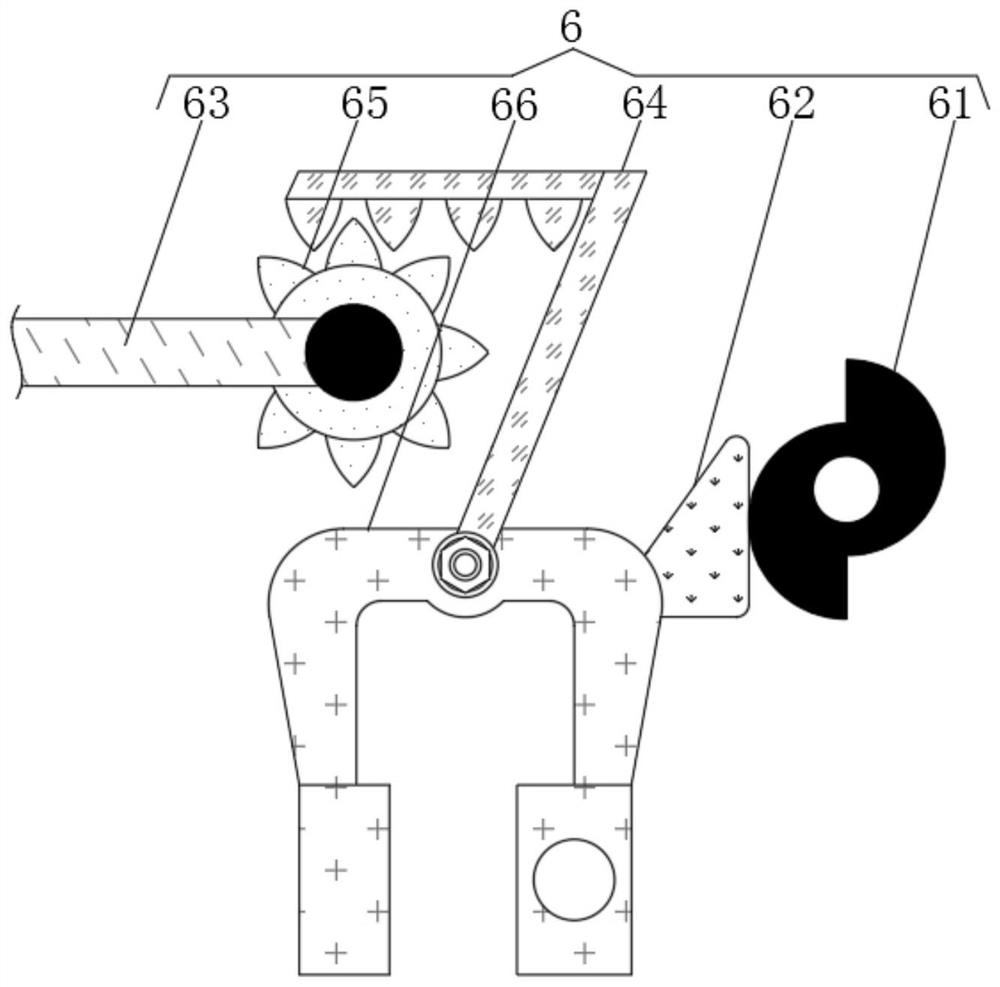

[0025] Adjusting mechanism 6 comprises rotating block 61, and the two ends of rotating block 61 are all movably connected with movable block 62, and the outside of movable block 62 is welded with connecting frame 63, and the top of connecting frame 63 is fixedly connected with movable rod 64, and the bottom of movable rod 64 A gear 65 is rotatably connected, and a connecting rod 66 is welded on the surface of the gear 65. The turning block 61 presents an inverted Z shape. There are two movable blocks 62 with the same specifications. The ends of the two movable blocks 62 that are far away from each other are fixedly connected with a connecting frame 63. Initially, the short axis end of the turning block 61 is in contact with the movable block 62 on its outside. ...

Embodiment 2

[0028] see Figure 1-3 , a plastic bottle recovery auxiliary device for solid waste treatment, comprising a shell 1, a hot roller 2, a cone wheel 3, a cone wheel 2 4, a drive mechanism 5 and an adjustment mechanism 6.

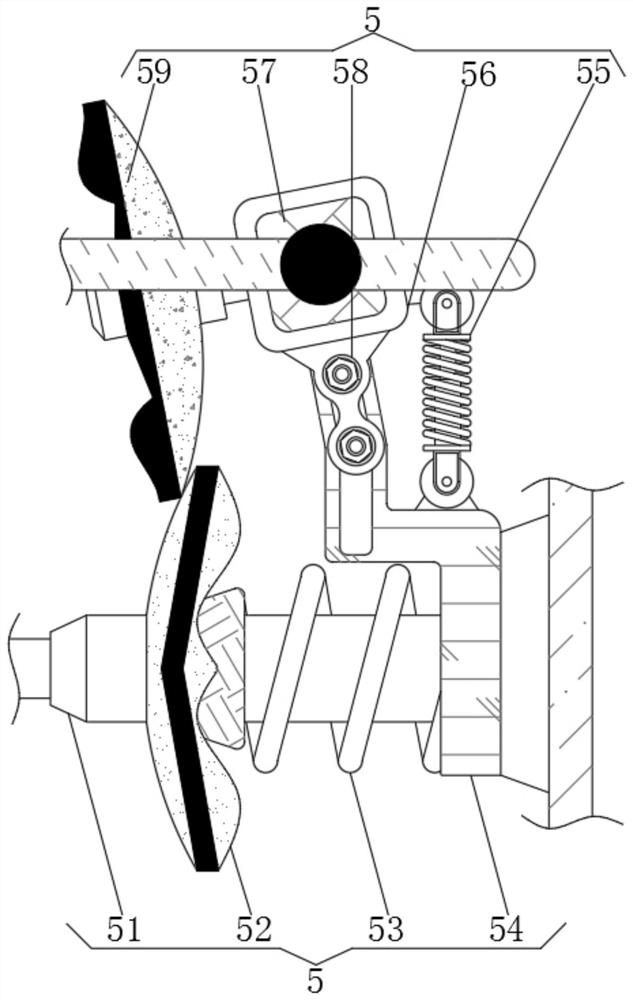

[0029] The driving mechanism 5 includes a telescopic rod 51, the outer tube of the telescopic rod 51 is clamped with a follower plate 52, the outside of the follower plate 52 is provided with a spring one 53, and the side of the spring one 53 away from the follower plate 52 is provided with a clamping plate 54, the top of clamping plate 54 is movably connected with spring two 55, and the surface of clamping plate 54 is slidably connected with clamping frame 56, and the inside clamping of clamping frame 56 is connected with motor 57, and the outside of clamping frame 56 is provided with clamping column group 58, and motor The outer side of 57 is provided with driving disc 59, and the inner bar of telescopic rod 51 is clamped in the through hole of connecting fra...

Embodiment 3

[0032] see Figure 1-3 , a plastic bottle recovery auxiliary device for solid waste treatment, comprising a shell 1, a hot roller 2, a cone wheel 3, a cone wheel 2 4, a drive mechanism 5 and an adjustment mechanism 6.

[0033] Adjusting mechanism 6 comprises rotating block 61, and the two ends of rotating block 61 are all movably connected with movable block 62, and the outside of movable block 62 is welded with connecting frame 63, and the top of connecting frame 63 is fixedly connected with movable rod 64, and the bottom of movable rod 64 A gear 65 is rotatably connected, and a connecting rod 66 is welded on the surface of the gear 65. The turning block 61 presents an inverted Z shape. There are two movable blocks 62 with the same specifications. The ends of the two movable blocks 62 that are far away from each other are fixedly connected with a connecting frame 63. Initially, the short axis end of the turning block 61 is in contact with the movable block 62 on its outside. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com