Automatic assembling equipment for terminal reverse insertion type connector

A technology for assembling equipment and connectors, which is applied to the assembly/disassembly of contact pieces, fixing/insulating contact components, etc. It can solve the problems of long manual assembly time, high defective rate, and low output, and achieve convenient material number switching , high yield rate, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The invention will be further described in detail below by examples to make those skilled in the art with reference to the specification text.

[0039] It should be understood that, such as "having", "including" and "comprising" as used herein do not exclude presence or addition of one or more other elements or combinations thereof.

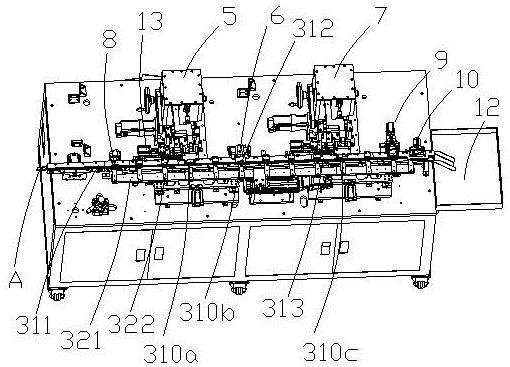

[0040] like Figure 1-3As shown, a terminal reverse insert type connector automated assembly device, including feeding system 1, terminal reverse interpolation system 2, dielectric system 3 and quality inspection mechanism 4;

[0041] The feed system includes a core feed device 110, a first terminal feeder 120, and a second terminal feed device 130;

[0042] The terminal reverse interpolation system includes a first terminal insertion device 5, a flip device 6, and a second terminal insertion device 7 disposed in the direction of the core A. The first terminal feed device is used to reverse the first terminal. The apparatus conveying terminal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com