Corn oil-based polyurethane porous material and preparation method thereof

A porous material and corn oil technology, applied in the field of automotive acoustic materials, can solve problems such as heavy pollution and unsatisfactory low-frequency sound absorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

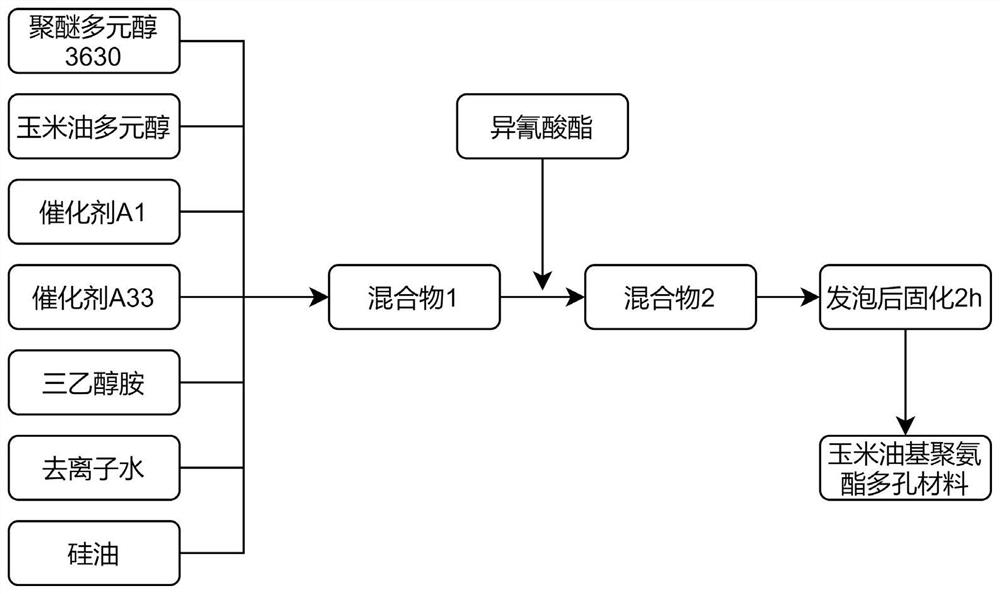

[0039] refer to figure 1 , a method for preparing a corn oil-based polyurethane porous material, comprising the steps of:

[0040] Step 1. Take the following raw materials according to the parts by mass:

[0041] Corn oil polyol: 40∽50 parts, polyether polyol: 50∽60 parts, silicone oil: 0.6 parts, triethanolamine: 2.5 parts, catalyst A1: 0.06∽0.1 parts, catalyst A33: 1.0 parts, deionized water: 2.5 parts Parts, isocyanate: 33∽38 parts;

[0042] Wherein, the hydroxyl value scope of described corn oil polyol is 190~210mgKOH / g;

[0043] Step 2. Put all the raw materials except isocyanate into the container, and use a stirring device to stir at a speed of 1000-1300 rpm for 1 minute to obtain a homogeneous mixture 1, and let it stand for 3-5 minutes;

[0044] Step 3, adding isocyanate and stirring at a rotation speed of 1100-1300 rpm to obtain a mixture 2;

[0045] When the isocyanate is added and stirred, the material begins to undergo a chemical reaction with an exothermic re...

Embodiment 1

[0051] Step 1, take the following raw materials according to the mass fraction:

[0052] Corn oil polyol: 40 parts, polyether polyol: 60 parts, silicone oil: 0.6 parts, triethanolamine: 2.5 parts, A1: 0.07 parts, A33: 1.0 parts, deionized water: 2.5 parts;

[0053] Isocyanate: 35 parts.

[0054] Step 2, put all the raw materials except isocyanate into the container, and use a stirring device to stir at a speed of 1000rpm for 1 minute to obtain a homogeneous mixture 1, and let it stand for 3 minutes;

[0055] Step 3: Add isocyanate and stir evenly at a rotation speed of 1300 rpm with heating to obtain mixture 2;

[0056] Step 4. Pour the mixture 2 into the mold for free foaming, and then put it into a 50°C incubator to cure for 2 hours;

[0057] Step 5, take it out from the incubator and cool to room temperature, then remove the surface crust to obtain a corn oil-based polyurethane porous material.

Embodiment 2

[0059] Step 1, take the following raw materials according to the mass fraction:

[0060] Corn oil polyol: 45 parts, polyether polyol: 55 parts, silicone oil: 0.6 parts, triethanolamine: 2.5 parts, A1: 0.07 parts, A33: 1.0 parts, deionized water: 2.5 parts;

[0061] Isocyanate: 33 parts.

[0062] Step 2. Put all raw materials except isocyanate into the container, and use a stirring device to stir at a speed of 1300 rpm for 1 minute to obtain a homogeneous mixture 1, and let it stand for 3 minutes;

[0063] Step 3, add isocyanate, and stir at a speed of 1200rpm evenly and accompanied by heat generation, the mixture 2 is obtained;

[0064] Step 4. Pour the mixture 2 into the mold for free foaming, and then put it into a 50°C incubator to cure for 2 hours;

[0065] Step 5, take it out from the incubator and cool to room temperature, then remove the surface crust to obtain a corn oil-based polyurethane porous material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com