Organic glass waste degradation process with high thermal efficiency

A technology of plexiglass and thermal efficiency, which is applied in organic chemistry, preparation of organic compounds, chemical industry, etc., can solve problems such as the tight combination between the inner cavity of aluminum alloy profiles and the inner lining of steel, so as to improve the efficiency of heat utilization and solve the problem of heat utilization low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

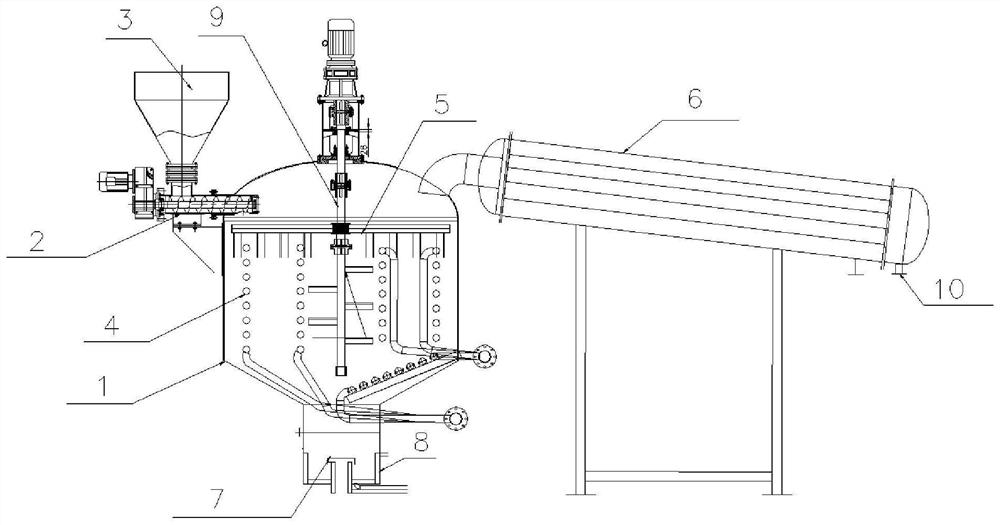

Image

Examples

Embodiment 1

[0040] A process for degrading plexiglass waste with high thermal efficiency, comprising the following steps:

[0041] (1) Put the plexiglass waste into the storage bin after descaling, and transport it into the cracking furnace by a screw conveyor;

[0042] (2) Through the material distributor in the cracking furnace, the organic glass waste is evenly distributed in the cracking furnace, so that the organic glass waste can be more fully contacted with the heating pipe in the cracking furnace;

[0043] (3) The heating tubes are distributed in the pyrolysis furnace in a ring shape, and the heating medium used by the heating tubes is heat transfer oil and molten salt, and the heating medium is heated to 400° C. through the heating medium heater;

[0044] (4) The heating medium circulates in the heating tube, and the heating time is 8 hours. During heating, the plexiglass waste is stirred by a stirrer, so that the plexiglass waste is heated more evenly. The stirring method is con...

Embodiment 2

[0048] A process for degrading plexiglass waste with high thermal efficiency, comprising the following steps:

[0049] (1) Put the plexiglass waste into the storage bin after descaling, and transport it into the cracking furnace by a screw conveyor;

[0050] (2) Through the material distributor in the cracking furnace, the organic glass waste is evenly distributed in the cracking furnace, so that the organic glass waste can be more fully contacted with the heating pipe in the cracking furnace;

[0051] (3) The heating tubes are distributed in the cracking furnace in a ring shape, and the heating medium used by the heating tubes is heat transfer oil and molten salt, and the heating medium is heated up to 420° C. through the heating medium heater;

[0052] (4) The heating medium circulates in the heating tube, and the heating time is 9 hours. During heating, the plexiglass waste is stirred by a stirrer, so that the plexiglass waste is heated more evenly. The stirring method is c...

Embodiment 3

[0056] A process for degrading plexiglass waste with high thermal efficiency, comprising the following steps:

[0057] (1) Put the plexiglass waste into the storage bin after descaling, and transport it into the cracking furnace by a screw conveyor;

[0058] (2) Through the material distributor in the cracking furnace, the organic glass waste is evenly distributed in the cracking furnace, so that the organic glass waste can be more fully contacted with the heating pipe in the cracking furnace;

[0059] (3) The heating tubes are annularly distributed in the cracking furnace, and the heating medium used by the heating tubes is heat transfer oil and molten salt, and the heating medium is heated to 390° C. through the heating medium heater;

[0060] (4) The heating medium circulates in the heating tube, and the heating time is 10 hours. During heating, the plexiglass waste is stirred by a stirrer, so that the plexiglass waste is heated more evenly. The stirring method is continuou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com