Rose, honey milk formula and preparation method thereof

A honey and formula technology, applied in the field of preparation of rose honey milk formula, can solve the problems that it is difficult to meet the growing demands of young consumers, rarely seen in milk rose beverages, and has a single flavor, taste and effect, and achieves good taste and reduced Nutrient loss, good taste and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

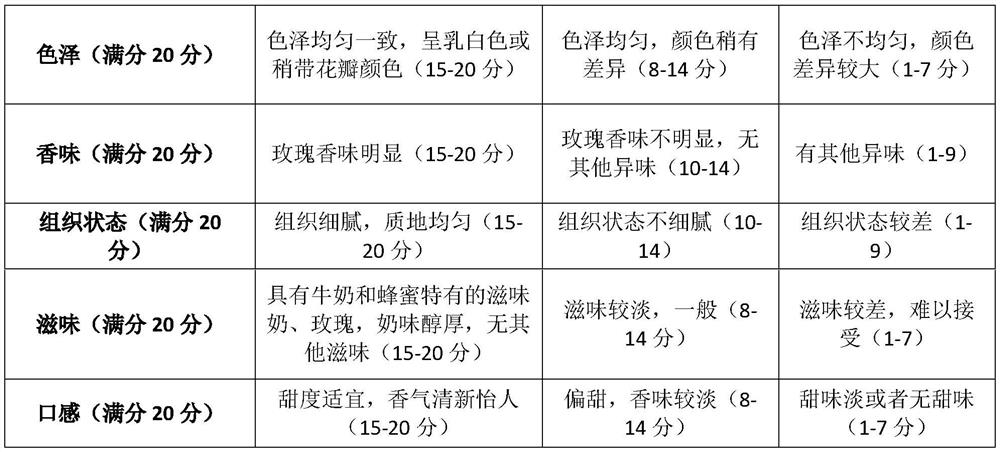

Examples

Embodiment 1

[0025] A rose honey milk formula, calculated in parts by weight, comprising the following raw materials: 80-90 parts of raw milk, 1.5-3 parts of honey, 0.1-0.5 parts of rose sauce, 0.025-0.04 parts of food flavor, mono- and diglycerin fatty acids 0.03-0.05 part of ester, 0.025-0.04 part of sucrose fatty acid ester, 0.035-0.06 part of sodium tripolyphosphate, 0.02-0.03 part of microcrystalline cellulose, 0.015-0.02 part of carrageenan, 0.025-0.04 part of sodium carboxymethyl cellulose , 10-14 parts of pure water.

[0026] A preparation method of rose honey milk formula, comprising the following steps:

[0027] Step S1: select the following substances by weight: 80-90 parts of raw milk, 1.5-3 parts of honey, 0.1-0.5 parts of rose sauce, 0.025-0.04 parts of food flavor, 0.03-0.05 parts of mono- and diglyceride fatty acid esters, 0.025-0.04 parts of sucrose fatty acid ester, 0.035-0.06 parts of sodium tripolyphosphate, 0.02-0.03 parts of microcrystalline cellulose, 0.015-0.02 par...

Embodiment 2

[0033] A rose honey milk formula, calculated in parts by weight, comprising the following raw materials: 80 parts of raw milk, 1.5 parts of honey, 0.1 part of rose jam, 0.025 parts of food flavor, 0.03 parts of mono- and diglyceride fatty acid esters, and 0.03 parts of sucrose fatty acid esters 0.025 parts, 0.035 parts of sodium tripolyphosphate, 0.02 parts of microcrystalline cellulose, 0.015 parts of carrageenan, 0.025 parts of sodium carboxymethyl cellulose, 10 parts of purified water.

[0034] A preparation method of rose honey milk formula, comprising the following steps:

[0035] Step S1: Select the following materials in parts by weight: 80 parts of raw milk, 1.5 parts of honey, 0.1 part of rose sauce, 0.025 parts of edible essence, 0.03 parts of mono- and diglyceride fatty acid esters, 0.025 parts of sucrose fatty acid esters, tripolyphosphoric acid 0.035 parts of sodium, 0.02 parts of microcrystalline cellulose, 0.015 parts of carrageenan, 0.025 parts of sodium carbox...

Embodiment 3

[0041] A rose honey milk formula, calculated in parts by weight, comprising the following raw materials: 85 parts of raw milk, 2.25 parts of honey, 0.3 part of rose sauce, 0.3 part of food flavor, 0.4 part of mono- and diglycerin fatty acid ester, 0.4 part of sucrose fatty acid ester 0.3 parts, 0.05 parts of sodium tripolyphosphate, 0.025 parts of microcrystalline cellulose, 0.15 parts of carrageenan, 0.3 parts of sodium carboxymethyl cellulose, 12 parts of purified water.

[0042] A preparation method of rose honey milk formula, comprising the following steps:

[0043] Step S1: Select the following materials in parts by weight: 85 parts of raw milk, 2.25 parts of honey, 0.3 part of rose sauce, 0.3 part of food flavor, 0.4 part of mono- and diglyceride fatty acid ester, 0.3 part of sucrose fatty acid ester, tripolyphosphoric acid 0.05 parts of sodium, 0.025 parts of microcrystalline cellulose, 0.15 parts of carrageenan, 0.3 parts of sodium carboxymethylcellulose, 12 parts of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com