Plasma tube with built-in resistor

A plasma tube and resistor technology, applied in the field of ion tubes, can solve problems such as failure of high-voltage oscillating lines to vibrate, decrease in product performance, and poor user experience. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

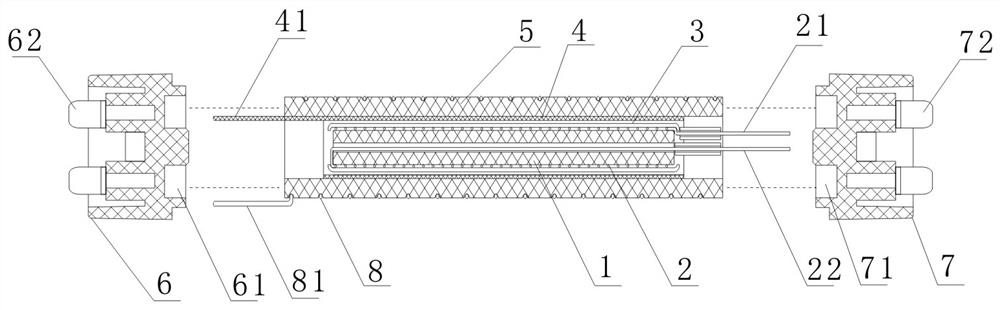

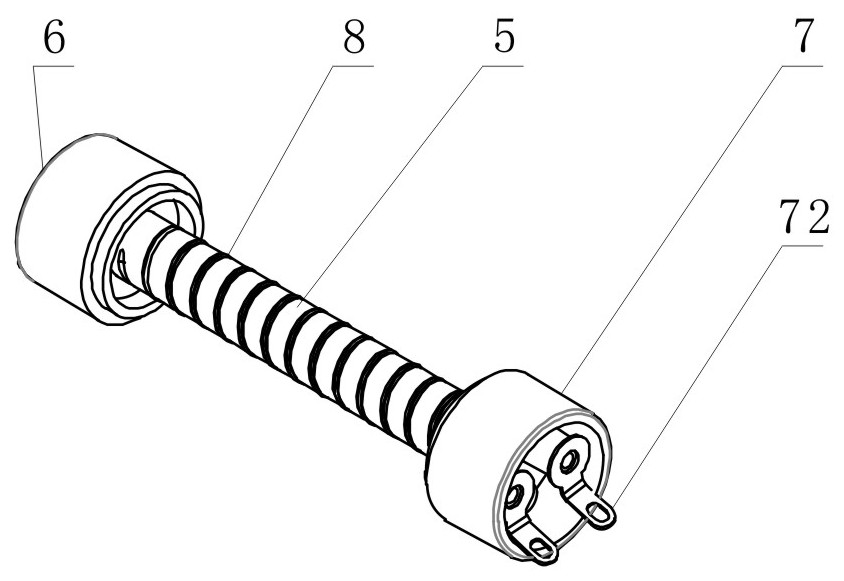

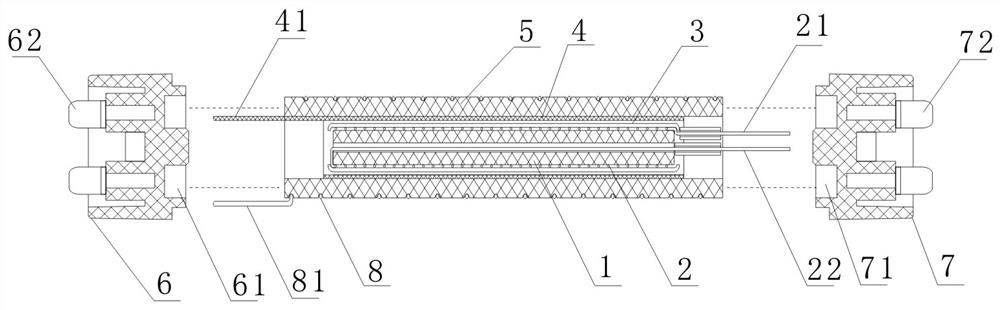

[0028] refer to figure 1 , figure 2 , the present invention includes a heating ceramic tube 1, a heating wire 2, a heat-shrinkable insulating sleeve 3, a stainless steel cylinder 4, an externally threaded ceramic tube 5, a high-voltage joint 6, a low-pressure joint 7 and a tungsten wire 8;

[0029] The heating ceramic tube 1 is a pipe fitting:

[0030] The heating wire 2 is wound by a metal wire into a spiral tube shape, one end of the spiral tube on the heating wire 2) leads to the first electrode 21, and the other end of the spiral tube leads to the second electrode 22;

[0031] The stainless steel cylinder 4 is a cylindrical part formed by curling a thin sheet, and the third electrode 41 is drawn from the thin sheet;

[0032] The externally threaded ceramic pipe 5 is a pipe fitting with a spiral groove on the outer surface;

[0033] The high-voltage joint 6 is in the shape of a circular platform, on which a first socket 61 and two high-voltage electrode pins 62 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com