Gradient electrode, preparation method thereof and super capacitor

An electrode and gradient technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of unstable electrode structure, easy falling off of active materials, and affecting capacitance performance, so as to reduce pulverization and falling off of active materials , reduce the binder content, improve the specific surface area and microporosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

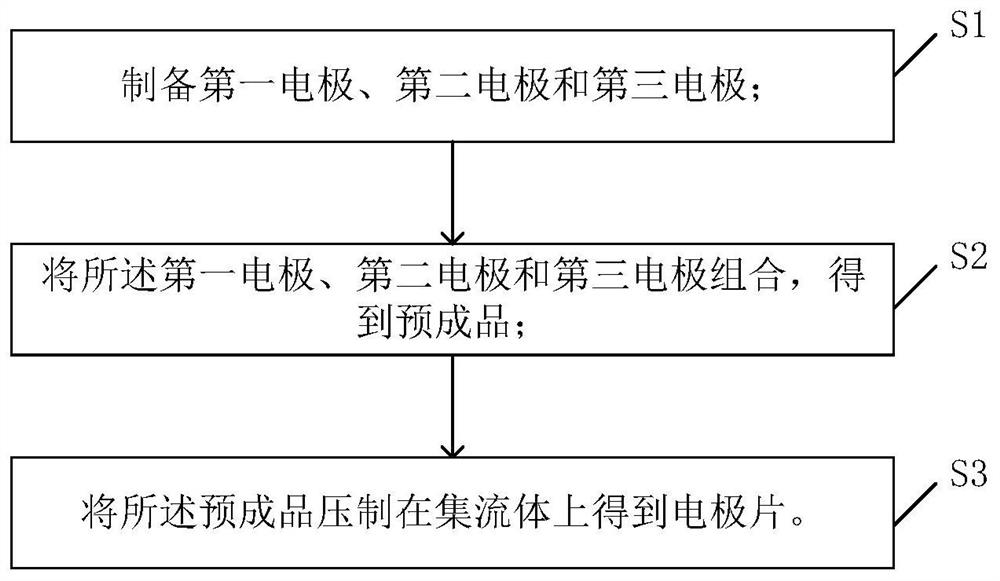

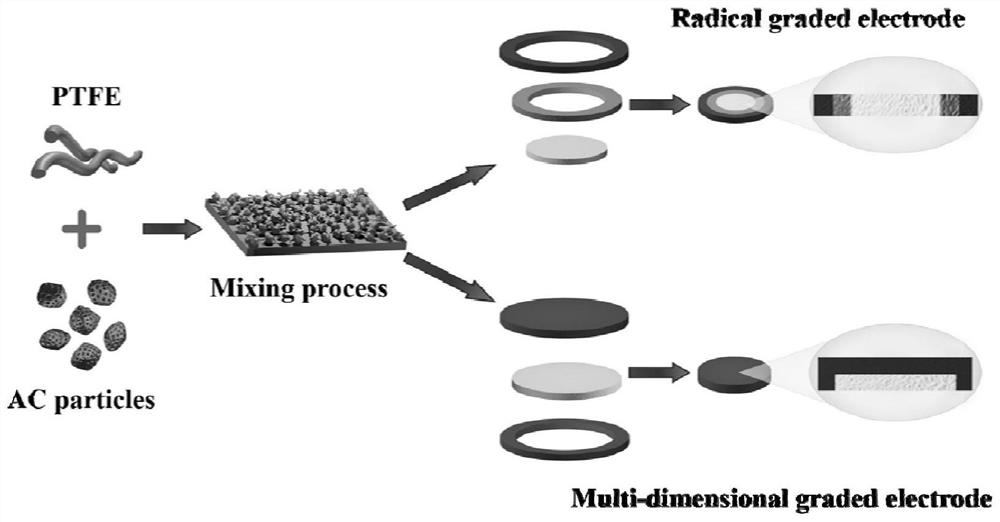

[0036] So, see figure 1 and figure 2 The present invention provides a method of preparing a gradient electrode, including:

[0037] S1: Preparation of the first electrode, the second electrode, and the third electrode;

[0038] Among them, the first electrode, the second electrode, and the third electrode are made of a binder and an active material, and the first electrode, the second electrode, and the third electrode have different adhesive content.

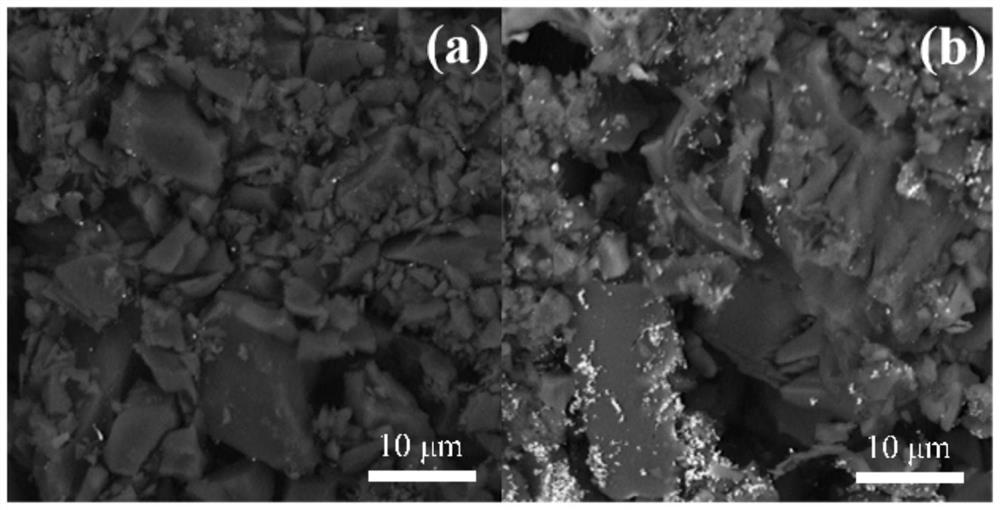

[0039] Specifically, the adhesive is a key portion that maintains the stable electrode structure, which acts on bonding the active material in the current collector to prevent the active substance from falling off from the current fluid. The active substance is a porous carbon material having a high surface area and a large amount of aperture. The adhesive is exemplary, PVDF, PTFE, CMC, but is not limited thereto. Preferably, the binder is PTFE.

[0040] Specifically, the first electrode is a sheet shape, and its shape is exemplary...

Example Embodiment

[0050] Example 1

[0051] (1) Preparation of a circular sheet-shaped first electrode having a PTFE content of 1 wt%, a diameter of 6 mm; a circular ring-shaped second electrode having a PTFE content of 3% by weight, an inner diameter of 8 mm; preparation The ring-shaped third electrode has a PTFE content of 5% by weight, an inner diameter of 8 mm, an outer diameter of 10 mm;

[0052] (2) Set the second electrode to the outer circumference of the first electrode, and the third electrode is arranged on the outer circumference of the second electrode, and the predeterior product is prepared;

[0053] (3) Prefillation is pressed under the pressure of 15 MPa to prepare the electrode sheet.

Example Embodiment

[0054] Example 2

[0055] (1) Preparation of circular sheet-shaped first electrodes having a PTFE content of 3 wt%, a diameter of 6 mm; a circular second electrode having a PTFE content of 4 wt%, an inner diameter of 8 mm; The ring-shaped third electrode has a PTFE content of 5% by weight, an inner diameter of 8 mm, an outer diameter of 10 mm;

[0056] (2) Set the second electrode to the outer circumference of the first electrode, and the third electrode is arranged on the outer circumference of the second electrode, and the predeterior product is prepared;

[0057] (3) Prefillation is pressed under the pressure of 15 MPa to prepare the electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com